- Removal and installation of an intermediate shaft Niva Chevrolet

- Removal and installation of Niva Chevrolet front wheel drives

- Interruptions in the operation of the Niva Chevrolet engine

- Features of the front suspension Niva Chevrolet VAZ-2123

- Niva Chevrolet brake disc replacement

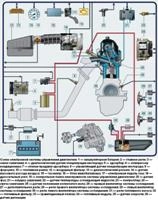

- Brake system VAZ-2123

- Removal and installation of the throttle assembly Niva Chevrolet

- Adjustment and replacement of the Niva Chevrolet throttle cable

- Replacing the parking brake cable Niva Chevrolet

- Removal and installation of the Niva Chevrolet controller

- Replacing the rear suspension shock absorber Niva Chevrolet

- Replacing the ball joint VAZ-2123

- Sensors of the Niva Chevrolet engine management system

- Replacing the front brake caliper Niva Chevrolet

- Setting the valve timing on the labels Niva Chevrolet

- How to replace the cylinder head gasket Niva Chevrolet

- How to replace the cylinder head cover gasket Niva Chevrolet

- Features of the VAZ-2123 power system

- Car body structure Niva Chevrolet

- Instrument cluster VAZ-2123

- The design of the front axle VAZ-2123

- Niva Chevrolet heater motor replacement

- Checking and replacing the Niva Chevrolet fuel pressure regulator

- Bleeding the hydraulic clutch VAZ -2123

- Removal and installation of a combination of devices Niva Chevrolet

- Chevrolet Niva front door repair

- Disassembly and assembly of the transfer case VAZ-2123

- Checking and replacing injectors Niva Chevrolet

- How to adjust the brake regulator VAZ-2123

- The design of the steering VAZ-2123

- Removal and installation of the gearbox VAZ-2123

- Repair and replacement of Niva Chevrolet windshield wipers

- Removal and installation of the front axle gearbox Niva Chevrolet

- How to remove the heating and ventilation control unit VAZ-2123

- Oil change in the front and rear axle Niva Chevrolet

- How to remove the brake drum Niva Chevrolet

- Fuses and relays VAZ-2123

- Replacing the power steering fluid VAZ-2123

- Replacement of the regulator of idling Niva Chevrolet

- No battery charging on Niva Chevrolet