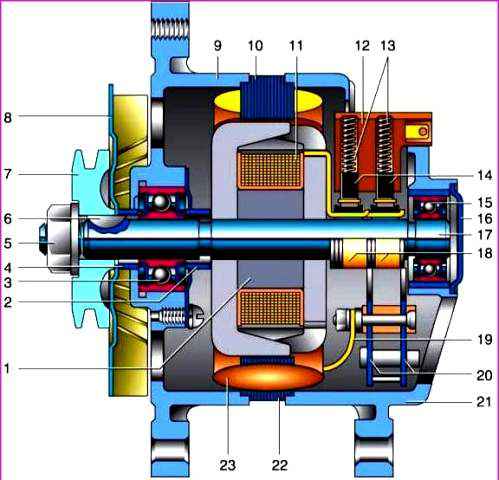

Generator 1601.3701 is a three-phase synchronous electric machine with electromagnetic excitation and built-in silicon diode rectifier

The generator is installed on cars with a ZMZ-402 engine.

The generator rotor is driven from the engine crankshaft pulley by a V-belt.

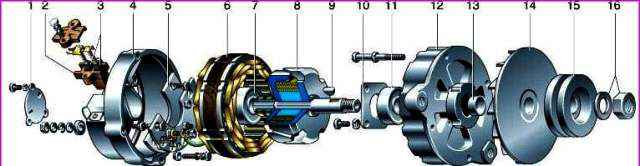

The stator and generator covers are held together with four screws.

The rotor shaft rotates in ball bearings installed in the covers.

The bearings are lubricated for the entire life of the generator.

The rear bearing is pressed onto the rotor shaft and is pressed by the rear cover through a plastic sleeve.

Generator 1601.3701: 1 - rotor; 2 - bushing; 3 - front bearing; 4 - bushing; 5 - nut with washer; 6 - key; 7 - pulley; 8 - impeller; 9 - front cover; 10 - stator; 11 - rotor winding; 12- brush holder; 13 - brush springs; 14 - brushes; 15 - rear bearing; 16 - cover; 17 - shaft; 18 - contact rings; 19 - output of the stator winding; 20 - plates of the rectifier block; 21 - back cover; 22 - a set of stator plates; 23 - stator winding

The front bearing is mounted on the inside of the front cover and secured with a washer and four screws.

In the stator of the generator, there are two three-phase windings made according to the "star" scheme and connected in parallel to each other.

Bridge rectifier, consists of six diodes.

They are pressed into two horseshoe-shaped aluminum holder plates.

The plates are combined into a rectifier unit, fixed inside the back cover of the generator.

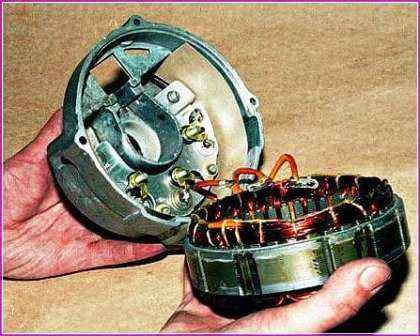

Generator parts 1601.3701:1 - bearing cover; 2 - brush holder; 3 - brushes; 4 - back cover; 5 - rectifier block; 6 - stator; 7 - rear bearing; 8 - rotor; 9 - key; 10 - front bearing cover; 11 - front bearing; 12 - front cover; 13 - thrust bushing; 14 - impeller; 15 - pulley; 16 - nut with washer

The excitation windings of the generator are located on the rotor.

The winding leads are soldered to two copper slip rings on the rotor shaft.

Power is supplied to them through two carbon brushes installed in the brush holder.

The generator works in conjunction with the voltage regulator, which is mounted on the front panel in the engine compartment.

When the regulator fails, it is replaced.

To protect the car's electronic equipment from voltage pulses in the ignition system, as well as to reduce radio interference, a capacitor is connected between the "+" and "ground" of the generator.

The internal windings of the generator and the rectifier unit are cooled by air through the windows in the covers from a centrifugal fan mounted on the rotor shaft.

Technical characteristics of the generator 1601.3701

Nominal voltage 14 V

Maximum current 65 A

Regulated voltage 13-15V

Excitation winding resistance 2.3-2.7 Ohm

Removing and repairing the generator

Disconnect the battery.

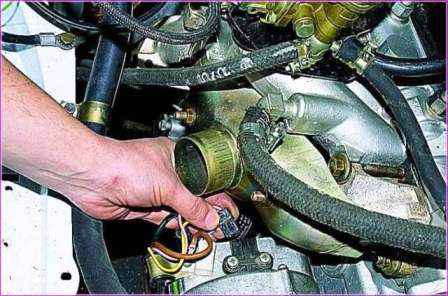

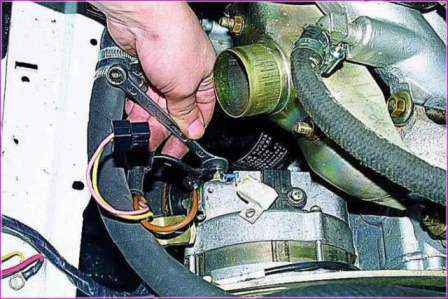

Disconnect the plug from the generator brush holder.

Use a slotted screwdriver to unscrew the screw and release the clamp for attaching the wires to the generator.

Use the key "10" to unscrew the nut and disconnect the wires from the generator.

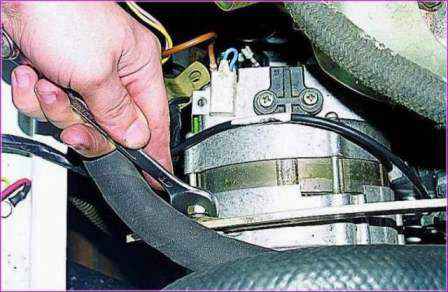

Using the “12” key, unscrew the bolt securing the generator to the tension bar

Remove the bolt together with the washers

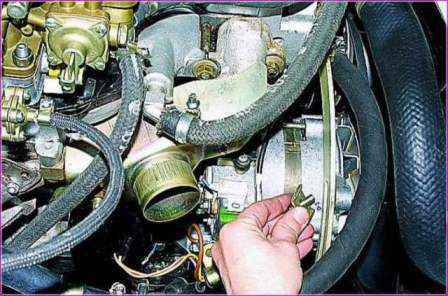

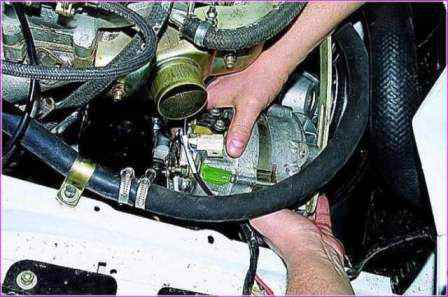

Using the “13” key, we loosen the tightening of the nut securing the bar to the cylinder head (for clarity, the cooling system hose is removed)

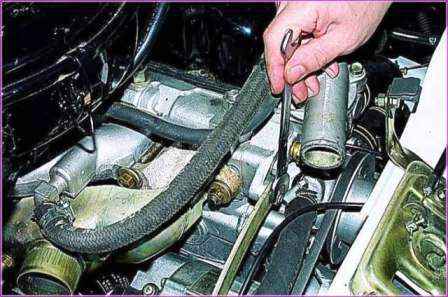

From the bottom of the car, sequentially holding the bolts of the lower mounting of the generator with the “14” key, unscrew the nuts with the “17” key.

Raising the generator up, remove it from the engine.

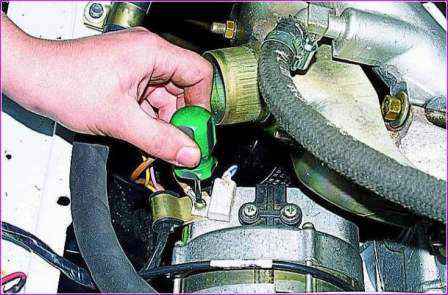

Use the "10" key to unscrew the nut of the contact bolt.

We unscrew the fastening screw and remove the capacitor.

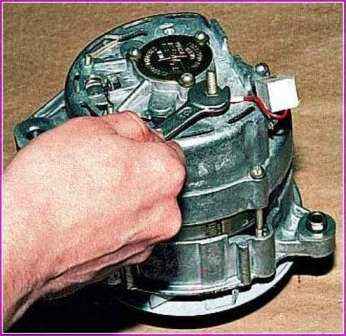

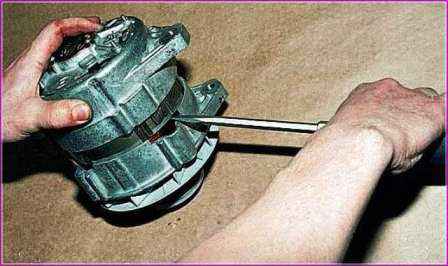

We unscrew the four screws that tighten the generator covers.

Prying off with a screwdriver, remove the back cover assembly with the stator.

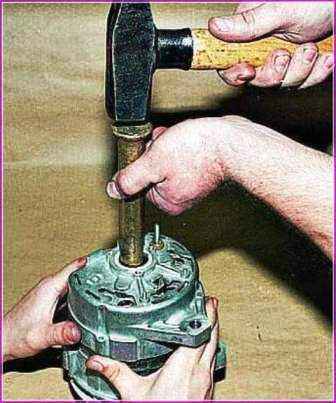

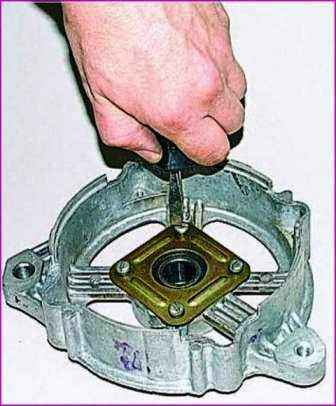

If it is not possible to disassemble the generator in this way, we unscrew the three screws securing the bearing cover.

Holding the generator on the weight of the stator, gently press the back cover with hammer blows through the soft metal mandrel

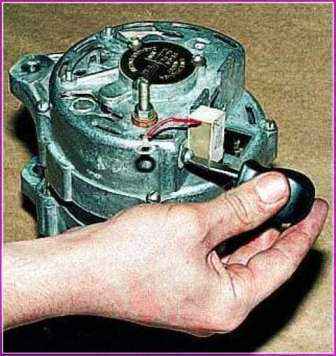

Using the “10” key, we unscrew the three nuts for fastening the leads

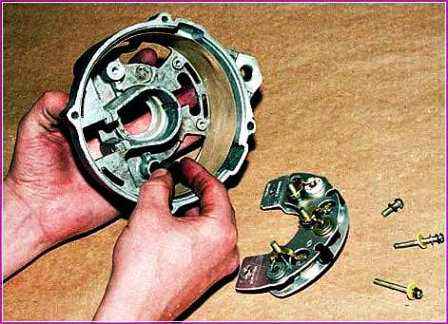

Remove the stator from the cover

Unscrew the nut with the “10” key

Having removed the insulating washer, we take out the contact bolt

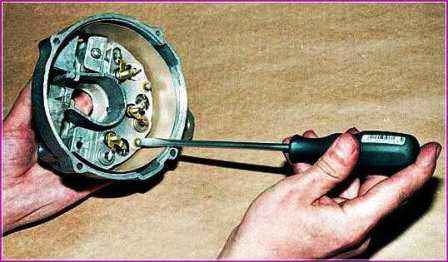

We unscrew the three screws securing the rectifier unit to the cover.

Having removed the block, we remove the insulating sleeve.

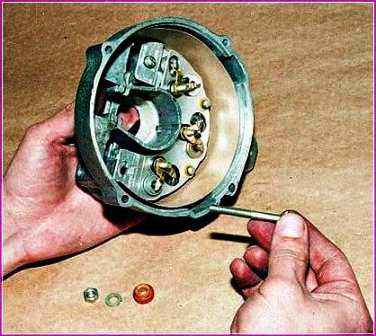

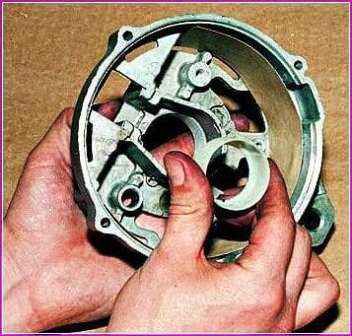

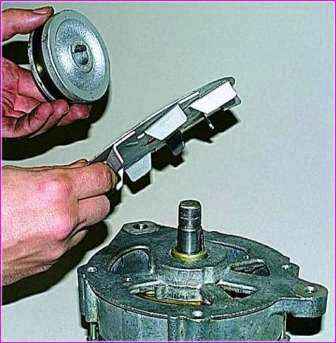

Remove the plastic bearing sleeve from the rear cover of the generator.

Remove two washers.

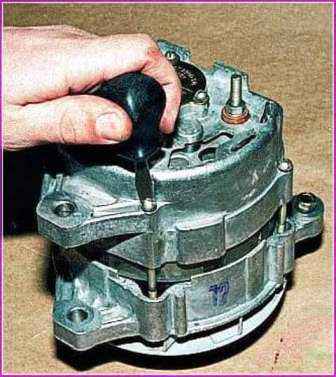

We put the nut on the threaded part of the rotor shaft flush with the end.

Holding the generator on the weight of the impeller, with light blows of a hammer through a soft metal drift, we knock out the pulley.

Having unscrewed the nut, remove the pulley and the impeller.

Knock out the key with a thin chisel or beard.

Remove the thrust sleeve.

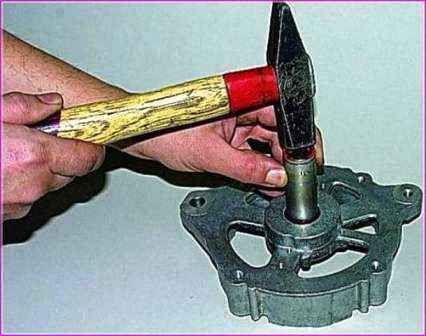

If there is no special puller, we screw the nut onto the shaft flush with the end and with a hammer, through a soft metal drift, knock the shaft out of the bearing.

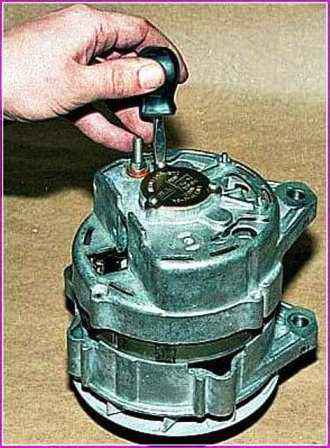

Using a screwdriver, unscrew the four screws securing the front bearing cover

Remove the cover.

We knock out the bearing through the mandrel

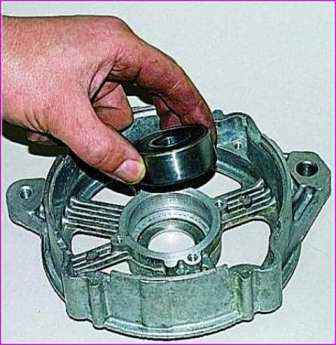

Installing a new bearing.

We press it in through a mandrel or a “36" head.

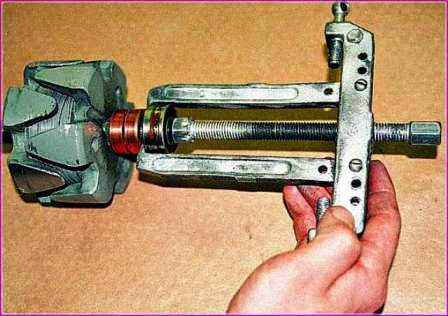

Using a puller, we dismantle the rear bearing from the rotor shaft.

We press in a new bearing with a suitable sleeve, applying force to the inner ring

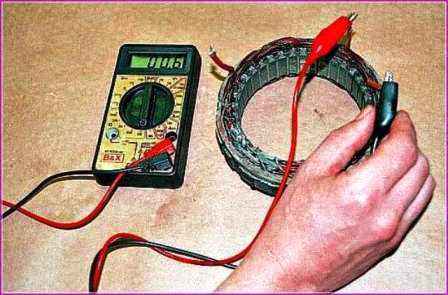

Using an ohmmeter, we check the absence of a short circuit in the stator winding to the case

Check for an open circuit in the stator winding

Check that the rotor winding is not shorted to the housing.

We measure the resistance of the excitation winding of the rotor, which should be in the range of 2.3–2.7 Ohm

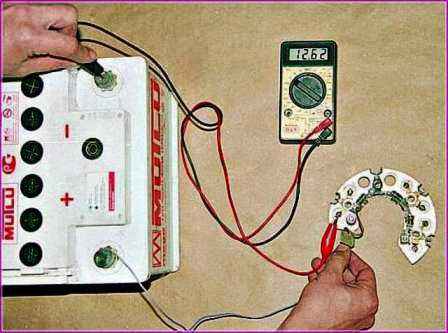

Applying voltage (12 V) of different polarity to the diodes, we check the condition of the rectifier unit

We replace the defective rotor and stator

Valves of the rectifier unit have one-way conduction.

A defective one usually passes current in both directions.

Replacement of individual valves is possible, but they will need to be repressed into a holder - an operation that requires accuracy and skill.

Therefore, in case of failure of its elements, we recommend replacing the rectifier unit as an assembly.

Before assembling, we clean the parts from dirt, oil and coal dust.

Assembling the generator in reverse order