Initial alternator express test can be performed directly on the vehicle

Checking the generator on vehicles with a ZMZ-402 engine

For cars with ZMZ-4025 and ZMZ-4026 engines, generators 16.3701 or 191.3701 are installed that are not equipped with a built-in voltage regulator.

These generators work in conjunction with an external transistor voltage regulator type 13.3702-01 or 50.3702, which has electronic protection against short circuit in the generator excitation winding circuit.

It is more convenient to do the work together.

We start the engine, let it run for a few minutes, then, pressing the "gas" pedal, we bring the crankshaft speed to 3000 min –1 .

Turn on consumers: high beam headlights; heater fan; wiper; alarm.

In this mode, we measure the voltage at the battery terminals, which should be higher than 12 V.

If this is not the case, the generator windings are faulty (open or short circuit), the voltage regulator with the brush assembly, the contact rings are oxidized or oily, the brushes are worn out or “stuck”.

In order to make sure that the voltage regulator is malfunctioning, we turn off all consumers except for the side light and measure the voltage at revolutions of 1000-1200 min -1, which should be in the range of 13.8-14.5 V .

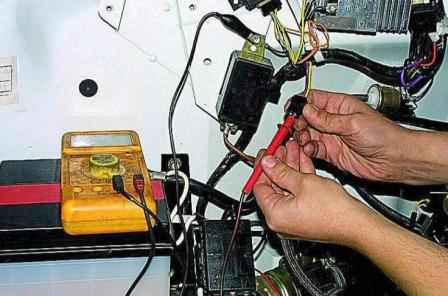

To check the excitation circuit of the generator, disconnect the connecting block from the regulator.

We attach a voltmeter or a test lamp to the “W” terminal of the block, and to the body of the voltage regulator.

Turn on the ignition

If there is no voltage (the lamp is off), one of the following malfunctions is possible:

- - violation of the contact of the excitation winding with slip rings; breakage of the excitation winding;

- - "hanging" of brushes in the channels of the brush holder; burning, oxidation and severe wear of the slip rings of the rotor.

Checking the alternator on vehicles with engines of the ZMZ-405, ZMZ-406 type

On engines of the ZMZ-406 and ZMZ-405 families, generators 9422.3701 or 5122.3771 with built-in integrated voltage regulators are installed.

We start the engine, let it run for a few minutes, then, pressing the "gas" pedal, we bring the crankshaft speed to 3000 min –1 .

Turn on consumers: high beam headlights; heater fan; wiper; alarm.

We measure the voltage at the battery terminals, which should be higher than 12 V.

If this is not the case, the generator windings are faulty (open or short circuit), the voltage regulator with the brush assembly, the excitation winding rings are oxidized or oily, the brushes are worn out or “hung”.

In order to make sure that the voltage regulator is malfunctioning, we turn off all consumers except for the side light and measure the voltage at 1000-1200 min -1 , which should be in the range of 13.5-14.2 V .

The removed voltage regulator can be checked as follows.

We connect a lamp between the brushes (21-35 W, 12 V).

We connect +12 V to the “D” terminal, and “minus” to the “ground” terminal.

The lamp should be on, and when the source voltage rises within 13.5–14.2 V, it should go out.

If the lamp is on in both cases, replace the regulator.

Checking the diodes of the rectifier unit and additional diodes.

In case of failure of its elements, we recommend replacing the rectifier unit as an assembly.

It is possible to replace individual diodes, however, they will need to be repressed into a holder - an operation that requires accuracy and skill.