The engine power system includes elements of the following systems:

- fuel supply system, including a fuel tank, an electric fuel pump module, pipelines, hoses, a fuel rail with injectors and a fuel pressure pulsation compensator;

- - air supply system, consisting of an air filter, an air supply sleeve and a throttle assembly;

- - a fuel vapor recovery system, including an adsorber, an adsorber purge valve and connecting pipelines.

The functional purpose of the fuel supply system is to ensure the supply of the required amount of fuel to the engine in all operating modes.

The engine is equipped with an electronic control system with multiport fuel injection.

In the system of distributed fuel injection, the functions of mixture formation and dosing of the air-fuel mixture supply to the engine cylinders are separated:

- injectors carry out metered injection of fuel into the intake pipe, and the amount of air required at each moment of engine operation is supplied by the throttle assembly

This control method makes it possible to ensure the optimal composition of the combustible mixture at each particular moment of engine operation, which allows you to get maximum power with the lowest possible fuel consumption and low exhaust gas toxicity.

The electronic engine control unit controls the fuel injection system to the ignition system, which continuously monitors the engine load, the vehicle speed, the thermal state of the engine, and the optimal combustion process in the cylinders using appropriate sensors.

A feature of the Toyota Camry injection system is the synchronous operation of the injectors in accordance with the valve timing (the engine control unit receives information from the phase sensor).

The controller turns on the injectors in series, not in pairs, as in asynchronous injection systems.

Each nozzle is activated through 720º of crankshaft rotation.

In starting and dynamic modes of engine operation, an asynchronous method of fuel supply is used without synchronization with the rotation of the crankshaft.

The main sensor for the fuel injection system is the oxygen concentration sensor in the exhaust gases (lambda probe).

It is installed in the engine exhaust manifold, combined with an exhaust gas converter (catcollector), and together with the engine control unit and injectors forms a control loop for the composition of the air-fuel mixture supplied to the engine.

Based on the signals from the sensors, the engine control unit determines the amount of unburned oxygen in the exhaust gases and accordingly evaluates the optimal composition of the air-fuel mixture entering the engine cylinders at any given time.

Having fixed the deviation of the composition from the optimal 1:14 (fuel and air, respectively), which ensures the most efficient operation of exhaust gas catalytic converters, the control unit changes the composition of the mixture using injectors.

Since the oxygen concentration sensor is included in the feedback circuit of the engine control unit, the air-fuel ratio control loop is closed.

A feature of the Toyota Camry engine management system is that, in addition to the control sensor, a second diagnostic oxygen concentration sensor is installed (in the exhaust pipe of the exhaust system).

By the composition of the gases that have passed through the converter, it determines the efficiency of the engine control system.

If the engine control unit, based on information received from the diagnostic oxygen concentration sensor, detects an excess of exhaust gas toxicity that cannot be eliminated by calibrating the control system, it turns on the engine malfunction warning light in the instrument cluster and stores an error code in memory for subsequent diagnostics.< /p>

The fuel tank is welded, stamped, installed under the floor of the body in its rear part and attached with two clamps so that fuel vapors do not enter the atmosphere, the tank is connected by a pipeline to the adsorber of the fuel vapor recovery system.

The fuel tank is fitted with a heat shield.

An electric fuel pump is installed in the flange hole in the upper part of the tank, on the left there are nozzles for connecting the filling pipe and the ventilation hose from the fuel module, including a fuel filter, pump and pressure regulator, fuel is supplied to the fuel rail mounted on the engine intake pipe.

From the fuel rail, fuel is injected into the intake pipe by injectors

The fuel lines of the power system are combined, in the form of interconnected steel and plastic pipelines, as well as rubber hoses.

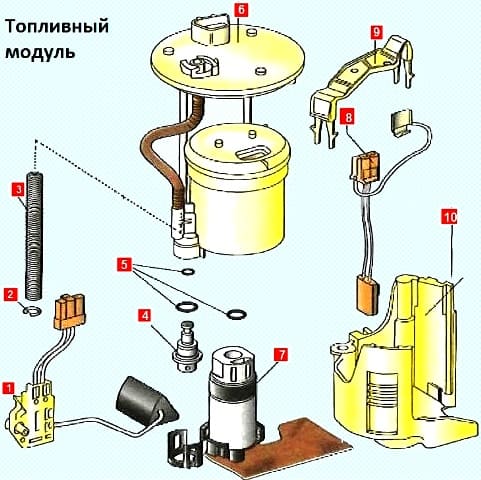

The fuel pump 7 is submersible with an electric drive, rotary type, with a mesh filter-fuel receiver is included in the fuel module.

The module is installed in the fuel tank, which reduces the possibility of vapor locks, since the fuel is supplied under pressure, and not under vacuum

The fuel pump supplies fuel from the fuel tank through the fuel line to the fuel rail at a pressure of 304-343 kPa.

The fuel filter is full-flow, structurally integrated with the body 6 of the fuel module. If the filter becomes clogged, the housing assembly must be replaced.

Fuel rail 2, which is a hollow tubular part with holes for installing injectors 1 and a compensator 3 for fuel pressure pulsations, serves to supply fuel to the injectors and is mounted on the cylinder head.

The nozzles and the pressure pulsation compensator are sealed in their sockets with rubber rings.

The injector rail assembly is inserted with injector shanks into the holes of the cylinder head and secured with two nuts.

The nozzle is designed for metered injection of fuel into the engine cylinder and is a high-precision electromechanical valve in which the shut-off valve needle is pressed against the seat by a spring.

When an electrical impulse is applied from the control unit to the electromagnet winding, the needle rises and opens access to the fuel to the nozzle holes - fuel is supplied to the engine intake channels.

The amount of fuel injected by the injector depends on the duration of the electric pulse.

In the holes of the cylinder head, the nozzles are sealed with rubber rings.

The fuel pressure pulsation compensator is installed at the end of the fuel rail and serves to maintain a constant fuel pressure in the rail when it drops sharply in the fuel line, caused, for example, by a significant increase in fuel consumption during intensive acceleration of the car.

The air filter is installed on the left side of the engine compartment on a special bracket.

Filter element made of non-woven material, flat, with a large filter surface area.

The filter is connected by a rubber corrugated air inlet sleeve to the throttle assembly

In order to reduce the noise of the air inlet to the air filter intake and air the inlet sleeve is connected to resonators specially selected in shape and volume.

The throttle assembly, which is the simplest control device, is mounted on the inlet flange of the intake pipe and attached with screws.

The throttle assembly is used to change the amount of main air supplied to the engine intake system.

A molded rubber sleeve is put on the inlet pipe of the throttle assembly, fixed with a clamp and connecting the throttle assembly to the air filter.

The throttle assembly includes a throttle position sensor and a throttle stepper motor.

There is no mechanical connection between the throttle assembly and the throttle control pedal

The so-called "electronic" throttle control pedal transmits information about the degree of depression on the pedal to the electronic engine control unit, which, in turn, taking into account the vehicle speed, gear engaged, engine load and engine speed, opens the throttle valve to the required corner