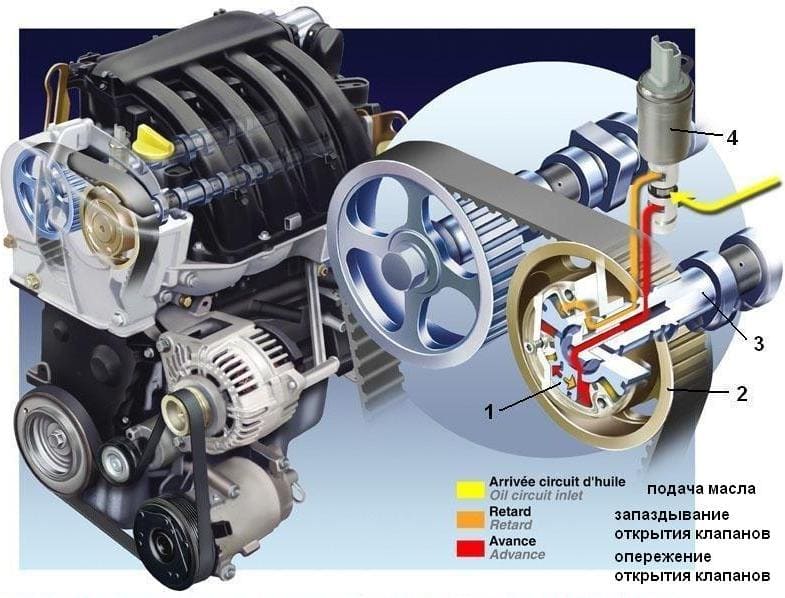

The phase regulator is designed to change the valve timing

To improve the filling of the cylinders with the working mixture in all modes, the K4M and F4R engines are equipped with an inlet camshaft phase regulator (Fig. 1).

Shifting the closing timing of the intake valves optimizes the filling of the cylinders depending on the speed of the crankshaft.

The result is increased torque at medium loads and power at high engine speeds.

Under these conditions, the later closing of the intake valves provides an additional portion of the fuel mixture due to its high speed.

On the contrary, at a low rotational speed, the inertia of the charge is small.

Earlier closing of the exhaust valves avoids poor filling of the cylinders and loss of torque due to the displacement of part of the fresh charge of the mixture.

The higher the engine speed, the later the intake valves should close.

Phase regulator operation modes (k4m engine)

Oil is supplied to the phase regulator through a solenoid valve mounted on the cylinder head (Fig. 2).

The valve is energized in the form of a variable signal of the degree of cyclic opening (amplitude 12 V and frequency 250 Hz), which allows oil to be supplied to the mechanism, and thus change the phase angle.

The ECU supplies the solenoid valve with an alternating signal of the degree of cyclic opening, the magnitude of which is proportional to the required phase shift.

The phases change smoothly from 0 to 43° along the angle of rotation of the crankshaft.

The camshaft dephaser solenoid valve is controlled under the following conditions:

- - no malfunction of the crankshaft speed sensor;

- - no malfunction of the camshaft position sensors;

- - no malfunctions in the injection system;

- – after starting the engine;

- - when the engine is not idling with the accelerator pedal released;

- - the threshold value of the injection profile, which is set taking into account the load and the crankshaft speed, has been received;

- – coolant temperature within 10–120°С;

- - increased engine oil temperature.

Backup Modes:

- - return of the phase regulator to its original position;

- – zero phase shift.

When the solenoid valve is locked in the open position, the engine idles unsteadily, the pressure in the intake manifold is increased, and the engine is noisy.

Operation and control of the phase regulator (f4r engine)

The phase control is disabled or is controlled by the injection computer via a solenoid valve mounted on the cylinder head cover (fig. 3).

When the crankshaft speed is between 1500-4300 min-1, the computer supplies power to the solenoid valve.

When 4300 min–1 is exceeded, the solenoid valve is de-energized.

At the same time, the position of the phase regulator mechanism contributes to filling the cylinders at a high crankshaft speed.

In this position, the locking plunger blocks the mechanism.

At speeds up to 1500 min–1, no voltage is applied to the solenoid valve.

The mechanism is blocked by a plunger.

From the moment power is applied to the solenoid valve at a crankshaft speed of more than 1500 min–1, under the action of oil pressure, the shut-off plunger moves away and releases the mechanism.

In the initial position, the solenoid valve is closed.

The valve opens the oil passage to control the phase regulator under the following conditions:

- - no malfunction of the wheel speed sensor start shaft;

- - no malfunction of the camshaft position sensors;

- - no malfunctions in the injection system;

- – after starting the engine;

- – the engine is not idling;

- - battery voltage is higher than 11.4 V;

- - coolant temperature above 30°С;

- – engine speed is 1500–4300 min–1;

- - load greater than 87% (approximately 900 Mbar).

When the solenoid valve is locked in the open position, the engine idles unstable, the pressure in the intake manifold is increased.

The replacement of the phase regulator is described in the article - How to replace the phase regulator of a 2.0l Renault Megane 2 engine