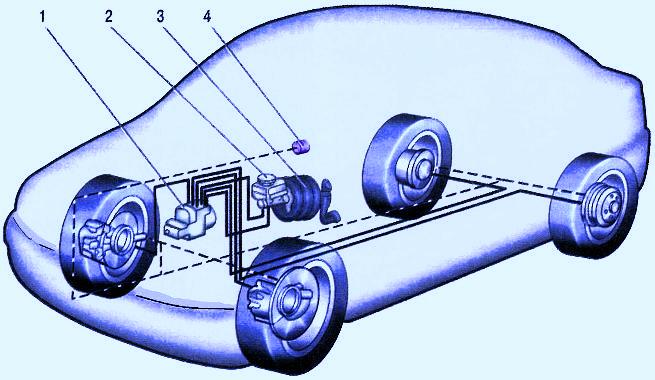

The anti-lock braking system (ABS) consists of an electronic control unit (ECU), wheel speed sensors, a hydraulic unit 1 (fig. 1) with hydraulic solenoid valves, an electrically driven return pump and a warning light 4 in the instrument cluster

ABS is used to regulate the pressure in the brake mechanisms of all wheels when braking in difficult road conditions, preventing the wheels from blocking.

The system provides the following benefits:

- - obstacle avoidance with a higher degree of safety, including during emergency braking;

- - reduction of the braking distance during emergency braking while maintaining roadholding and controllability of the car, including when turning.

In the event of a system failure, a function is provided to maintain operation in case of system failures.

The electronic control unit (ECU) receives information about vehicle speed, direction of travel and road conditions from wheel speed sensors.

Based on this information, the control unit determines the optimal wheel braking mode, changing the flow sections of the circuits using the electromagnetic valves of the hydraulic unit, anticipating the moment of blocking the slowing wheel, which prevents it from blocking.

If the system expects a wheel to be blocked, it instructs the appropriate valve to isolate the fluid supply to that wheel's slave cylinder from the brake master cylinder.

If a wheel's speed continues to decrease relative to the other wheels, the ABS system returns the brake fluid back to the master cylinder, reducing braking.

If all four wheels decelerate equally, the return pump will shut off and all solenoid valves will open again, allowing the brake master cylinder to act on the slave cylinders normally.

This cycle can repeat up to ten times per second.

The activation of the solenoid valves and the return pump creates pulsations in the hydraulic drive of the brake system, they are transmitted to the brake pedal, thereby signaling to the driver that the ABS is working.

The solenoid valves in the circuits of the brake mechanisms of the front wheels act on their working cylinders independently, on each separately, while the solenoid valve of the circuits of the brake mechanisms of the rear wheels acts on both working cylinders of the mechanisms simultaneously.

Because the braking system is diagonally split, a separate mechanical plunger valve in the hydraulic block separates the hydraulic output of the rear solenoid valve into two separate circuits.

In order to prevent false signals from affecting the system, a built-in safety loop monitors all signals entering the ECU.

If a false signal is received or the voltage in the on-board electrical network is insufficient, the system is automatically turned off, the ABS deactivation warning lamp in the instrument cluster lights up.

In this case, the normal operation of the brake system is preserved, however, when driving on a slippery road, you need to be extremely careful, since the distribution function of the system is violated (the function of equalizing the pressure in the brake mechanisms of the front and rear wheels) and there is a possibility of skidding the car when braking.

If there is a malfunction in the ABS system, contact a service station, as special equipment is required to diagnose and repair it.

The hydraulic brake system is integrated into a single unit with metal pipes and hoses.

The system is filled with a special brake fluid of at least DOT-4 class, which must be replaced periodically.