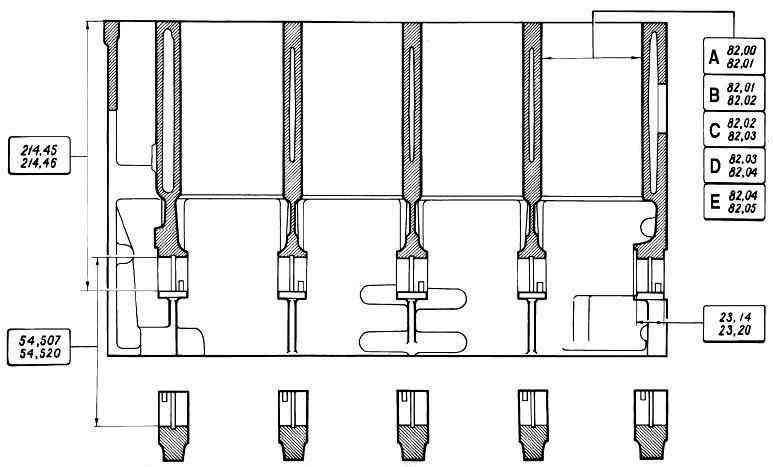

The main dimensions of the cylinder block are given in Figure 1.

Cylinder block cast from special low-alloy cast iron

Cylinder diameters are divided into five classes through 0.01 mm, denoted by the letters A, B, C, D, E.

The cylinder class is stamped on the bottom plane of the cylinder block

It is possible to bore cylinders for repair pistons, increased in diameter by 0.4 and 0.8 mm.

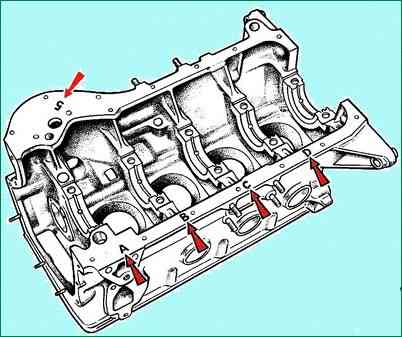

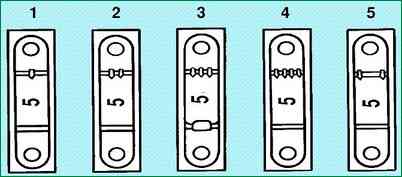

Main bearing caps are machined complete with cylinder block.

Therefore, they are not interchangeable and have risks on the outer surface to distinguish them (Fig. 3).

Checking the technical condition and repair

Wash the cylinder block thoroughly and clean the oil passages.

Blow and dry with compressed air, inspect the cylinder block. Cracks in bearings or other places in the cylinder block are not allowed.

If there is a suspicion that coolant has entered the crankcase, then check the tightness of the cylinder block on a special stand.

To do this, after plugging the holes in the cooling jacket of the cylinder block, inject water at room temperature into it at a pressure of 0.3 MPa (3 kgf / cm 2).

There should be no water leakage from the cylinder block for two minutes.

If oil gets into the coolant, then without completely disassembling the engine, check for cracks in the cylinder block in the areas of the oil channels.

To do this, drain the coolant from the cooling system, remove the cylinder head, fill the cooling jacket of the cylinder block with water and supply compressed air to the vertical oil channel of the cylinder block.

If air bubbles appear in the water filling the cooling jacket, replace the cylinder block.

Check the split plane of the cylinder block with the head using a ruler and a set of feeler gauges.

The ruler is set along the diagonals of the plane and in the middle in the longitudinal direction and across. The flatness tolerance should not exceed 0.1 mm.

Repair of cylinders

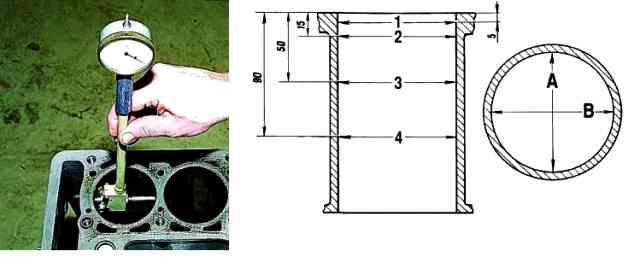

Check if the wear of the cylinders exceeds the maximum allowable - 0.15 mm.

The cylinder diameter is measured by a bore gauge (Fig. 4) in four zones, both in the longitudinal and transverse directions of the engine. A micrometer is used to set the inside gauge to zero.

In the zone of belt 1, the cylinders practically do not wear out. Therefore, by the difference in measurements in the first and other zones, one can judge the amount of cylinder wear.

If the maximum wear value is more than 0.15 mm, bore the cylinders to the nearest repair size, leaving an allowance of 0.03 mm for the honing diameter.

Then honing the cylinders, maintaining such a diameter that when installing the selected repair piston, the estimated clearance between it and the cylinder is 0.025–0.045 mm.

Replacing end caps

Replacing oil channel plugs:

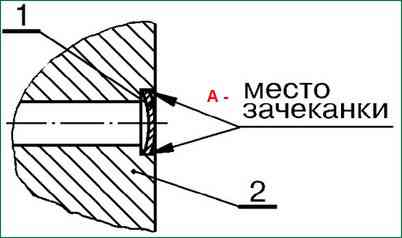

- - drill in the center of the plug 1, figures 5 and 6, a hole with a diameter of 4-5 mm;

- - remove the stub from block 2;

- - deburr, clean and degrease the seating surface under the plug;

- - degrease the new plug;

- - apply anaerobic glue on the seating surface of the cylinder block under the plug (anaerobic glue AN-112);

When installing end cap 1/01586/01:

- - install the plug 1, (Fig. 5), into the hole of the oil channel and upset;

- - mint the fit of the plug;

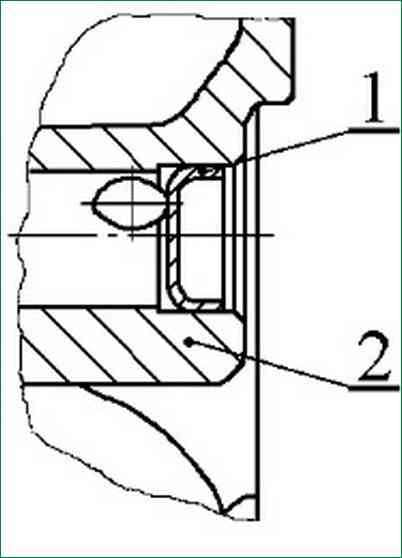

when installing plug 21083-1002046:

- - install the plug 1, (Fig. 6), into the hole in the oil channel and press it in using a mandrel. The pressing depth is provided technologically (mandrel 67.7853-9631).

Replacing the cooling system plugs:

- - drill a hole in the plug with a diameter of 6-7 mm at a distance of 1/4 of its diameter from the edge, as shown in Figure 7;

- - push the plug on the side diametrically opposite to the hole until a gap appears between the inner wall of the cylinder block and the edge of the plug;

- - insert firmware or a technological rod into the hole and remove the plug from the cylinder block;

- - deburr, clean and degrease the seating surface under the plug;

- - degrease the new plug;

- - apply anaerobic glue on the seating surface of the cylinder block under the plug (anaerobic glue AN-112);

- - install a new plug (drill 67.7853-9590 for plugs 00001-0043299-01-0 with a diameter of 40 mm, mandrel 67.7853-9591 for plugs 00001-0043289-01-0 with a diameter of 25 mm, hammer).