The cylinder block is cast from gray cast iron and is made in the form of a monoblock with the crankcase part lowered below the crankshaft axis

Between the cylinders in the upper part there are channels made in the casting for the passage of coolant.

There are five main bearing seats at the bottom of the block.

Ductile iron main bearing caps are machined with the cylinder block and are therefore not interchangeable.

On the bottom surfaces of the 1st, 2nd and 4th covers, their numbers are embossed for correct installation.

When installing the covers, the locking grooves for the liners in the cylinder block and in the covers should be located on one side.

Blocks with holes in the cylinder walls, with cracks on the upper plane of the block and on the ribs supporting the main bearings, with holes in the water jacket and crankcase are to be rejected.

As a result of natural wear, the cylinders in the block acquire the shape of an irregular cone along the length, and an oval along the circumference.

The wear reaches the greatest value in the upper part of the cylinders against the upper compression ring, when the piston is at TDC, the smallest is in the lower part, when the piston is at BDC.

Cylinders and pistons are divided into five size groups A, B, C, D, E.

The cylinder group letter is inked on the left outer side of the block opposite each cylinder.

All cylinders in one block should, as a rule, be machined to the same repair size with a tolerance of +0.036...+0.072 mm from the face value, except when it is required to remove shallow scratches on the cylinder mirror (within the magnification cylinder diameter by 0.10 mm), only defective cylinders can be repaired here.

In cases where only a limited number of pistons are available, it is recommended to calculate the nominal diameter for each cylinder based on the actual size of the piston skirt diameter intended to work in this cylinder, and machine cylinders to this size with the following machining tolerance .

Deviations from the geometrically correct shape of the cylinders should be located within the tolerance field of the size group for the cylinder diameter.

The tightness of the cooling jacket is checked by pressing.

To do this, you need to plug all the holes in the block, except for one, to which compressed air is supplied. The block is lowered into a bath of water and compressed air is supplied at a pressure of 1.5 atm.

Air bubbles will come out in damaged areas.

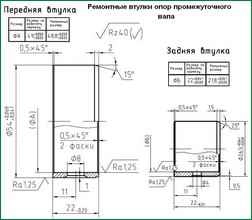

Repair of the bushings of the intermediate shaft supports consists in replacing them with standard or repair bushings, of increased thickness, depending on the wear of the mounting holes in the cylinder block and subsequent boring of the inner hole of the bushings to a standard or repair size, depending on the wear of the intermediate shaft bearing journals.

Make repair bushings from anti-friction alloy.

Standard bushings should be replaced with repair bushings also when they loosen or turn.

Before installing the intermediate shaft supports, remove the tube.

When installing repair bushings, ensure that the holes of the oil channels match.

Bore the intermediate shaft bearings in one setting to ensure alignment. Press the new tube onto the anaerobic sealant.

The intermediate shaft journals are ground to the repair size in case of wear exceeding the maximum allowable.

If the holes for the oil pump drive are worn more than allowed, bore the holes to the repair size for the repair bushings.

Make repair sleeves from gray cast iron with an outer diameter of 21 mm and a length: lower - 17 mm, upper - 30 mm.

Press the repair bushings, drill a through hole for oil supply Ø 3.5 mm in the upper bushing through a hole with a conical thread, which enters the oil line of the cylinder block, and machine the holes in the bushings to the nominal size.

Machining the mounting holes of the cylinder block for the bushings and the holes of the bushings should be done in one installation.

Damage to threaded holes, in the form of nicks or stripped threads of less than two threads, is repaired by threading with a tap of normal size.

Threaded holes with wear or thread breaks of more than two threads are repaired by cutting threads of an increased repair size, threading new screw drivers and then threading them to a normal size or installing threaded spiral inserts, the latter method of repair is the most effective and less laborious.

Controlled parameters during the repair of the cylinder block, pistons, connecting rods and intermediate shaft

*tolerance of 0.036 mm is divided into 3 groups - through 0.012 mm

* 0.010 mm tolerance is divided into 4 size groups - 0.0025 mm each