The vehicle's fuel assembly consists of a high pressure fuel pump unit, a fuel tank, fuel injectors and fuel connecting pipes (fuel lines)

The functional purpose of the fuel supply system is to ensure the supply of the required amount of fuel to the engine in all operating modes

The engine is equipped with an electronic control system with multiport fuel injection

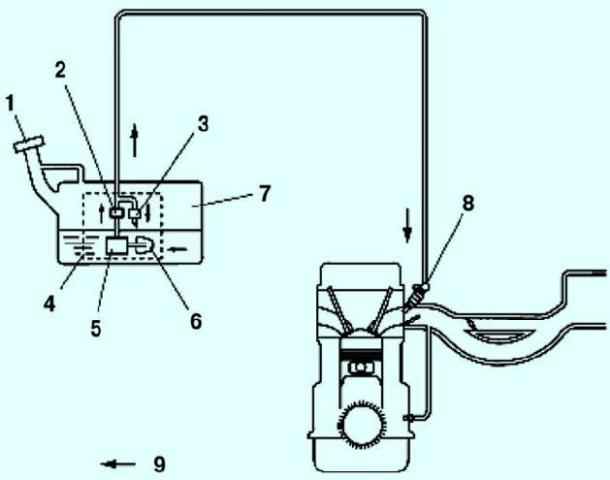

From the fuel tank, the fuel pump delivers fuel under pressure to the fuel line, from where it enters the cylinders through injectors. The nozzles dose and spray the fuel.

When voltage is applied to the solenoid winding, the needle rises, passing fuel.

The amount of fuel is determined by the duration of the pulse during which the nozzle is open.

The fuel then flows back into the fuel tank through two metal tubes located under the bottom of the vehicle.

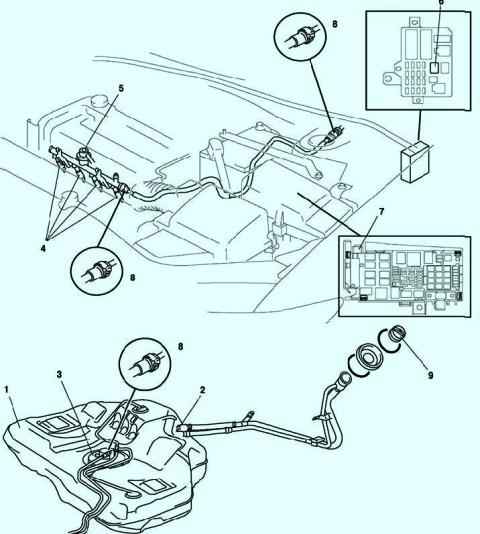

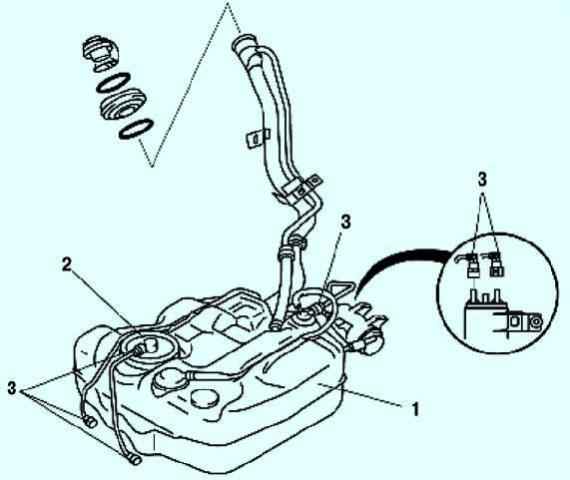

The fuel pump is installed in the fuel tank (fig. 1).

Checking the tightness of the fuel lines

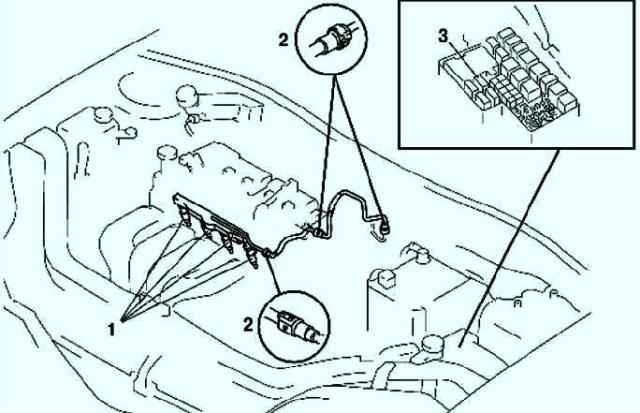

Inspect the connection of the pressure pipe to the fuel rail

Inspect the connection of the injectors to the fuel rail

Inspect the fuel lines of the fuel tank and their attachment to the underbody

If cracks, abrasions, or leaks of fuel are found, replace damaged fuel lines. Also replace damaged fasteners.