Replace the hub bearing when play appears.

Bearing wear can be identified by increased noise when the vehicle is moving

Operations for replacing a hub bearing with and without ABS are similar. The only difference is the installed speed sensor in the steering knuckle.

Preparing the car for work.

We install the car on a viewing hole or a lift.

In order to unscrew the hub nut, place stops under the wheels.

Usually, the hub nut is tightened with great force, so you need an assistant to apply the brake while unscrewing the nut.

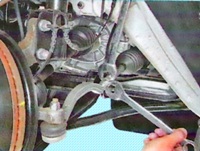

With a head at 32 (Fig. 1), unscrew the wheel bearing nut.

Hang out and remove the wheel.

Remove the front wheel speed sensor (if installed).

Remove the brake disc.

Using the TorxT-30 key, unscrew the three screws securing the brake shield to the steering knuckle and remove the shield.

Disconnect the tie rod end from the steering knuckle

Remove the ball joint pin from the steering knuckle hole

Disconnect the shock absorber from the steering knuckle

Remove the steering knuckle (Figure 2) assembly with the hub from the splined shank of the wheel drive outer hinge housing.

When removing the steering knuckle from the drive, try not to pull the drive shaft out of the CV joint or gearbox.

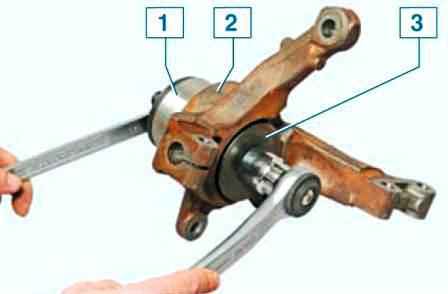

Let the steering knuckle rest on the vise jaws (Figure 3).

By striking the end of the hub through a mandrel or head of the appropriate size

We press out the hub. In this case, the inner ring of the bearing, located closer to the hub flange, remains on the hub.

Use a screwdriver to pry off the protective washer that covers the bearing seal

Remove the washer.

We clamp the hub flange in a vice.

Insert a chisel between the ends of the inner ring of the bearing and the shoulder of the hub.

By striking the chisel with a hammer, we move the inner ring of the bearing along the hub.

Then, in the resulting gap, we insert the grips of the puller and finally press the inner ring of the bearing from the hub.

Using circlip pliers, remove the bearing circlip from the knuckle groove.

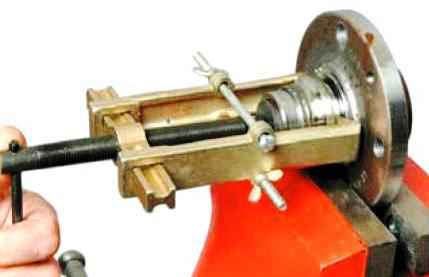

Using a cup puller, we press the bearing out of the collar fist.

The bearing can also be punched out. to do this, we rest our fist on the vise jaws.

By striking the end of the outer ring of the bearing through a mandrel or head of a suitable size, we press the bearing out of the knuckle.

Before installing a new bearing, we clean the mounting hole in the steering knuckle and the groove for the retaining ring.

Using a file, we clean the nicks from the chisel on the hub.

Before pressing the bearing, we put the adjusting ring of the wheel speed sensor into the hole of the steering knuckle (with the tabs centering the ring - inside the fist).

Orient the ring in the knuckle hole so that the speed sensor holder on the ring 1 (Figure 13) is located in the knuckle groove 2 (shown on the assembled hub assembly for clarity).

After installing the cup puller screw with the support washer, insert a new bearing into the knuckle hole.

On a vehicle with ABS, install the bearing so that its dark-colored shield (made of magnetic material) faces the wheel speed sensor mounting ring.

Figure 15 shows the details of the hub assembly.

We press the bearing, applying force through the puller cup to the end of the outer ring of the bearing, while the puller washer should rest on the steering knuckle (Figure 16).

After pressing the bearing, we install a retaining ring in the groove of the fist.

Then we press the hub into the bearing.

When pressing the hub, the puller cup must rest on the end face of the bearing inner ring (Figure 17).

Further assembly and installation of the hub assembly is carried out in the reverse order.