We replace the auxiliary drive belt on a car equipped only with power steering every 60 thousand km or after 4 years (whichever comes first) regardless of its condition, on other cars - after 120 thousand km or after 6 years

We perform work on a viewing ditch or overpass.

Depending on the vehicle configuration, there are three options for auxiliary drive schemes:

- - with power steering and air conditioning;

- - with power steering, without air conditioning;

- - without power steering and air conditioning.

We recommend checking the condition of the belt at every maintenance.

The belt must be replaced if cracks, tears and delamination of rubber from the fabric base are found on it.

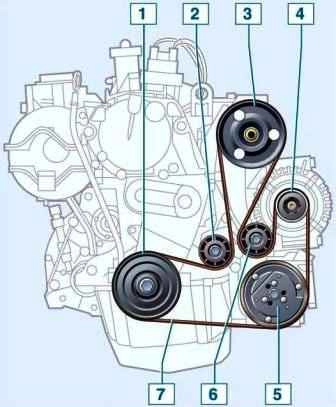

Option 1 (with power steering and air conditioning)

The belt tension of a car with power steering and air conditioning is adjusted automatically by the tensioner.

To replace the belt, remove the right mudguard of the engine compartment.

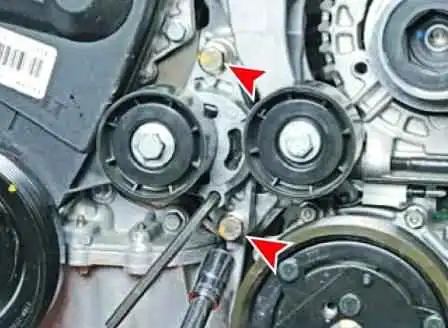

To loosen the belt tension, from the bottom of the car we put a spanner wrench or a 1Z head on the tension roller mounting bolt and turn the roller bracket clockwise, overcoming the spring force of the tensioner, until the hole in the roller bracket and the recess in the device body are aligned (for clarity shown with removed engine).

We fix the roller bracket by inserting a hexagon 6 or a rod with a diameter of 6 mm into its hole and a recess in the body of the tensioner.

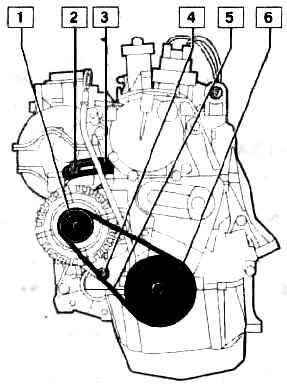

Scheme of the drive of auxiliary units of a car with power steering and air conditioning:

Remove the accessory drive belt.

Marking of the drive belt for auxiliary units of a car with power steering and air conditioning - 5K 1747 (five-wedge, 1747 mm long).

When replacing the belt, the idler and idler rollers must also be replaced.

To replace the support roller with a ring wrench or a 1Z head, unscrew its fastening bolt

Remove the bolt with the protective cover of the roller

Remove the support roller.

We also remove the tension roller.

To replace the tensioner, turn off the two bolts securing the tensioner housing with a 13 head and remove the tensioner yours is assembled with a roller.

Install the removed parts in reverse order.

Before mounting the belt, the idler pulley bracket must be turned clockwise and locked.

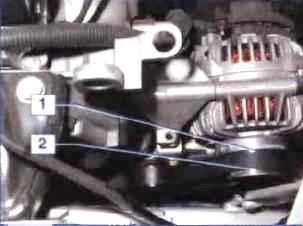

We lay the belt on the pulleys so that it is shifted to their outer edge 1, and the inner stream of pulleys 2 remains free

When installing the belt, we lay it on the pulleys and wind it under the tension and support rollers in accordance with the drive diagram.

The drives of auxiliary units, the generator, the air conditioning compressor and the power steering pump are six-stranded, and the drive belt is five-wedge.

After installing the belt, slightly turning the tension roller with a wrench, remove the latch.

Then, with an 18 head with a ratchet, turn the crankshaft clockwise three turns for the bolt securing its pulley to achieve the correct position of the belt.

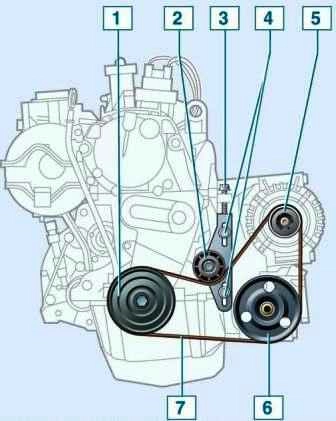

Option 2 (with power steering, without air conditioning)

Checking the tension of the belt of auxiliary units of a car with power steering and without air conditioning, the manufacturer recommends using a special tool (tensometric tester).

Given that the belt may need to be changed on the way (for example, if it breaks), away from the service, we will show a method in which you can approximately estimate the belt tension.

Excessive belt tension leads to premature failure of the belt and idler, as well as accessory bearings.

Remove the right mudguard of the engine compartment.

From the bottom of the car with your thumb, press the belt in the middle between the pulleys of the power steering pump and the crankshaft.

With a pressing force of 10 kgf, the deflection of the belt should be 6-8 mm.

To tension the belt, loosen the two bolts 4 fastening the tension roller bracket and turn the adjusting bolt 3 clockwise.

Having tightened the belt, we tighten the bolts of the tension roller.

To replace the belt, loosen the bolts 4 fastening the tension roller bracket and turn the adjusting bolt 3 counterclockwise a few turns.

Release the tension of the belt, remove it from the pulleys.

Marking of the drive belt for auxiliary units of a car with power steering and without air conditioning - 5K1110 (five-wedge, 1110 mm long).

When replacing a belt, the tensioner pulley must also be replaced.

Install the accessory drive belt in reverse order.

The pulleys for the drive of auxiliary units, the generator and the power steering pump are six-stranded, and the drive belt is five-wedge.

We lay the belt on the pulleys so that it is shifted to the inner edge of the 1 pulleys, and the outer stream of the pulleys 2 remains free.

Adjust the tension of the belt.

Option 3 (without power steering and air conditioning)

To check the tension of the alternator drive belt on a car without power steering and without air conditioning, press the belt with your thumb in the middle between the alternator and crankshaft pulleys.

With a pressing force of -10 kgf, the deflection of the belt should be 6-8 mm.

To tension the belt, remove the right mudguard of the engine compartment.

Weaken bolt 4 of the lower fastening of the generator and bolt 2 of fastening the generator to the tension bar.

Moving the generator away from the engine block with a mounting blade, we tighten the belt.

Tightening the alternator mounting bolts

When replacing the belt, loosen its tension and remove the belt from the crankshaft and generator pulleys.

The marking of the alternator drive belt on a car without power steering and without air conditioning is 4RK718 (four-wedge, 718 mm long).

Install the alternator drive belt in reverse order and adjust its tension.