It is not necessary to remove the engine to remove the cylinder head

To prevent damage to the paintwork of the wings of the body, it is necessary to use a special coating

To prevent damage to the cylinder head, wait until the engine has cooled down before removing it.

When removing the metal cylinder head gasket, be careful not to miss it or damage the contact surface of the block with the head.

When disconnecting a wire, apply force directly to the connector, not the wire.

To avoid incorrect connection, it is necessary to put labels on all wires.

Turn the crankshaft pulley to set the piston of the first cylinder to the top dead center (TDC) position.

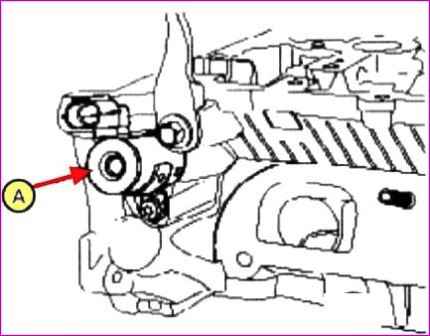

Disconnect the negative and positive terminals (A) from the battery.

Remove the engine cover (A).

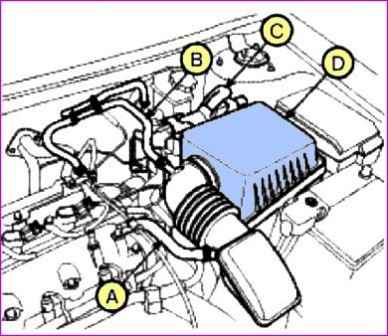

Remove the duct (A).

Disconnect the vent hose (A), vacuum hose (B), ECM connector (C) and remove the air filter assembly.

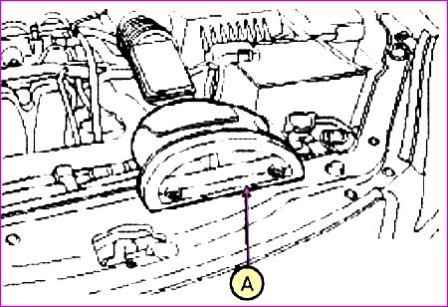

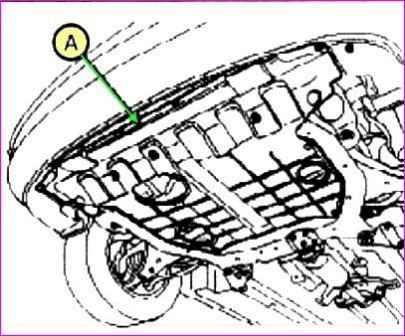

Remove the bottom cover (A).

Unscrew the drain plug and drain the coolant.

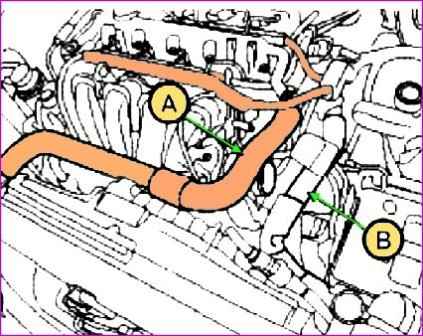

Remove the upper radiator hose (A) and the lower hose (B).

Remove the heater hose (A).

Disconnect the VIS connector (A), OPS(B), knock sensor (C) and A/C switch connector.

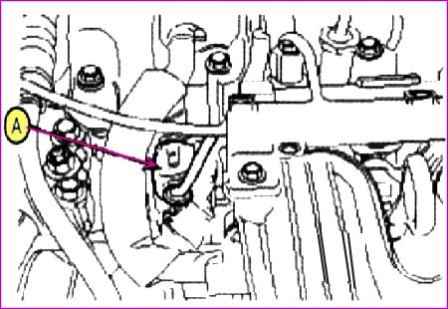

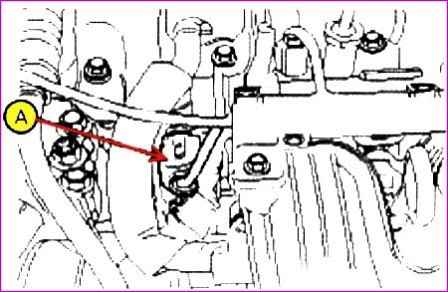

Disconnect the intake valve connector (A).

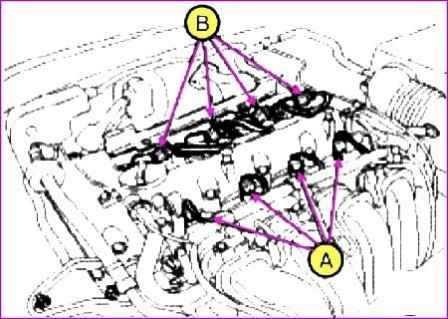

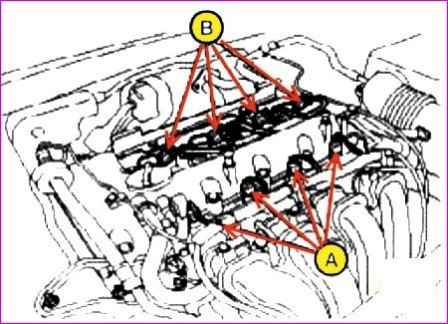

Disconnect the injector connectors (A) and ignition coils (B).

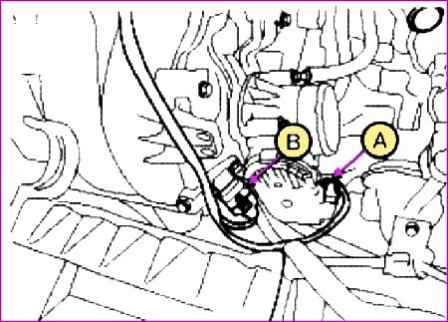

Disconnect the electronic timing control connectors (A) from the absolute air pressure sensor (B)

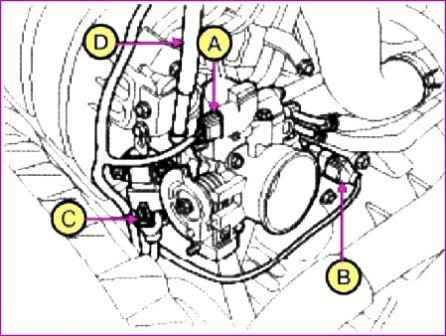

Disconnect the connectors for idle control (A), throttle position sensor (B), and mass air flow sensor (C), then remove the cable.

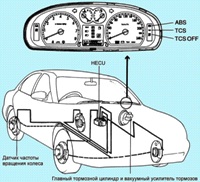

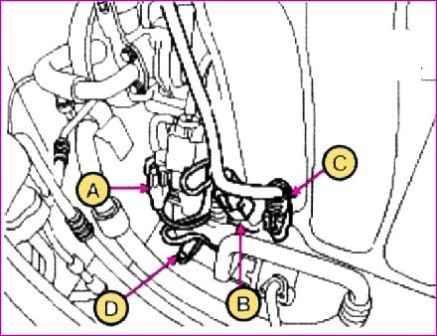

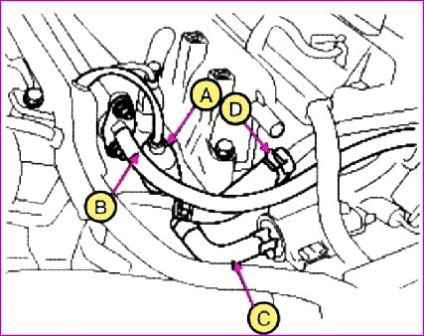

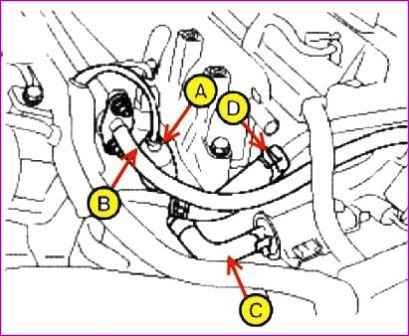

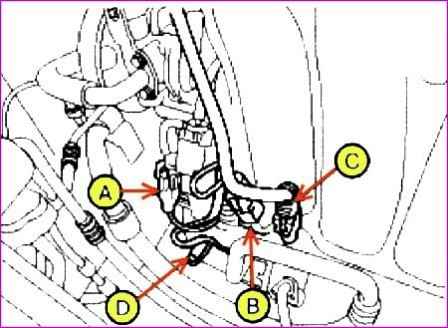

Disconnect the camshaft position sensor (A), fuel hose (B), brake booster vacuum hose (C) and positive crankcase breather hose (D) connectors.

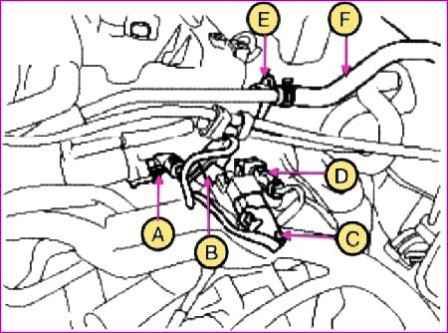

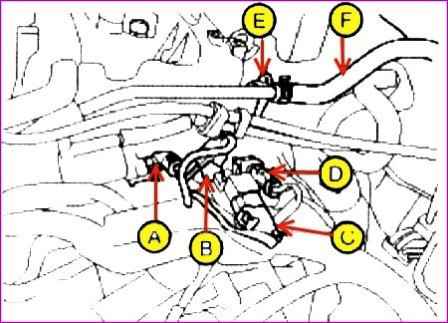

Disconnect the connector from the positive crankcase breather hose (A), electronic ignition timing control (B), capacitor (C), crankshaft position sensor (D), camshaft position sensor (E), and brake booster vacuum hose (F).

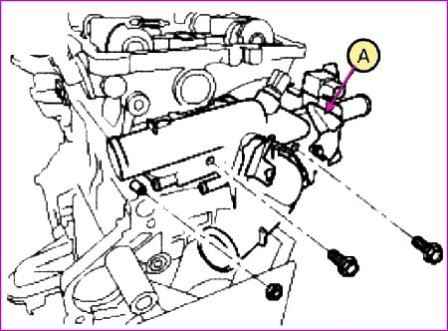

Remove thermostat assembly (A).

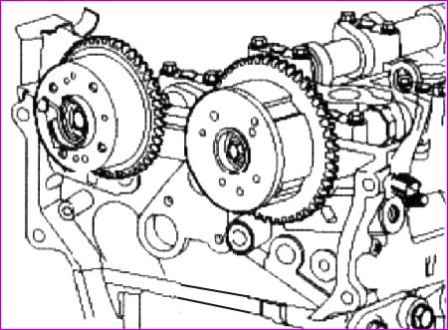

Remove the timing chain.

Remove the intake and exhaust manifolds.

Remove the intake and exhaust sprockets.

Remove the camshaft.

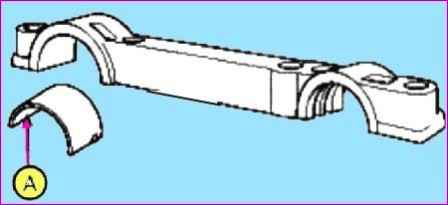

Remove the camshaft bearing front cover (A).

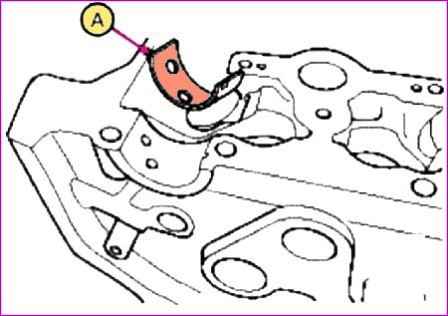

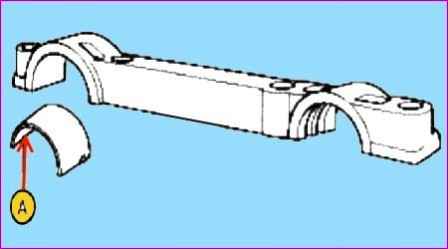

Remove the upper exhaust camshaft bearing (A).

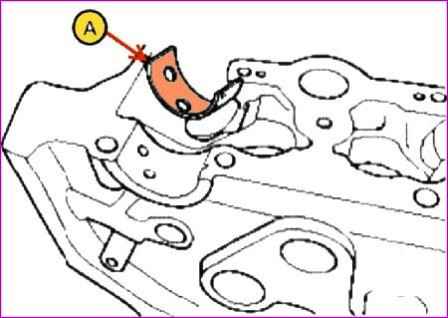

Remove the insert cover (A) as shown.

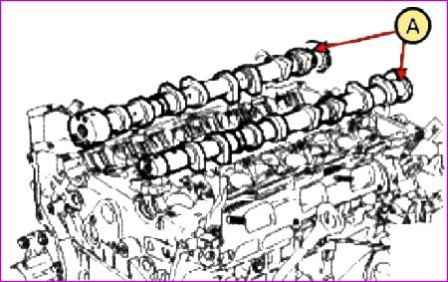

Remove the camshaft (A).

Remove the lower exhaust camshaft bearing (A)

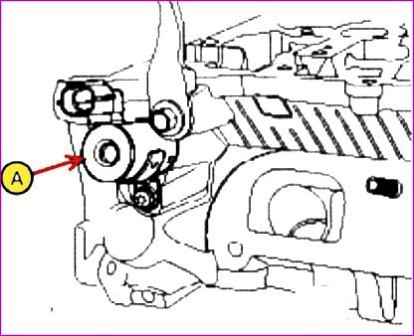

Remove the oil pressure control valve (A)

Remove the exhaust valve.

Remove the cylinder head bolts, then remove the cylinder head.

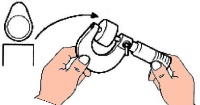

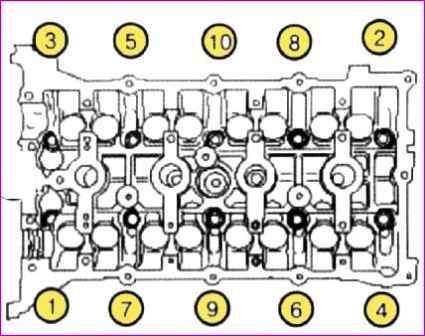

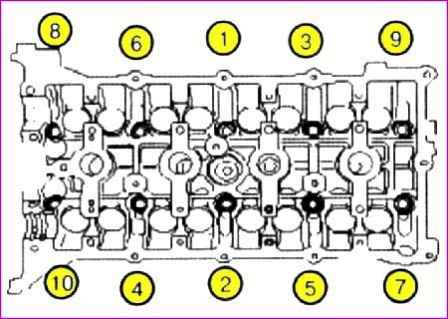

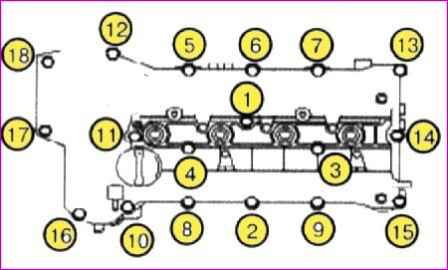

Using the special tool, remove the 10 cylinder head bolts in the order shown in the picture

Incorrect installation may result in damage to the cylinder head.

Remove the cylinder head from the guide pin on the cylinder block and place it on wooden blocks.

Be careful not to damage the contact surfaces of the head and cylinder block.

Remove the cylinder head gasket c.

Installing the cylinder head

Wash all parts before installation.

Always use a new cylinder head gasket and exhaust and intake manifold gaskets

Always use new cylinder head bolts

The cylinder head gasket is metal, you must be careful not to bend it before installing.

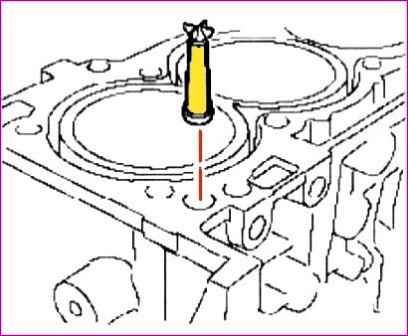

Turn the crankshaft clockwise to set the piston of the first cylinder to the TDC position.

Set filter.

Keep the filter clean

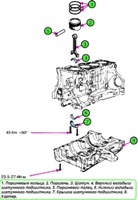

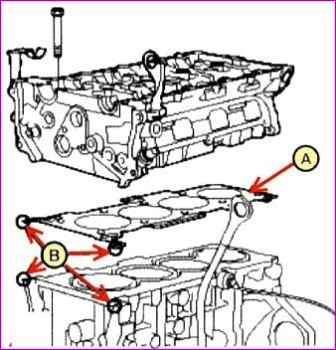

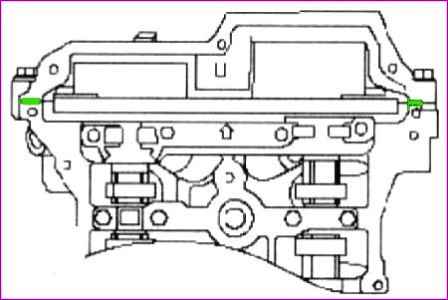

Install the cylinder head gasket (A) on the cylinder block.

Be careful about the installation order.

Apply sealant to mark (B).

After applying the sealant, the block head must be installed within 5 minutes.

Install the block head carefully so as not to damage the gasket.

Install the cylinder head bolts.

Apply a thin coat of engine oil to the threads and under the cylinder head bolt heads.

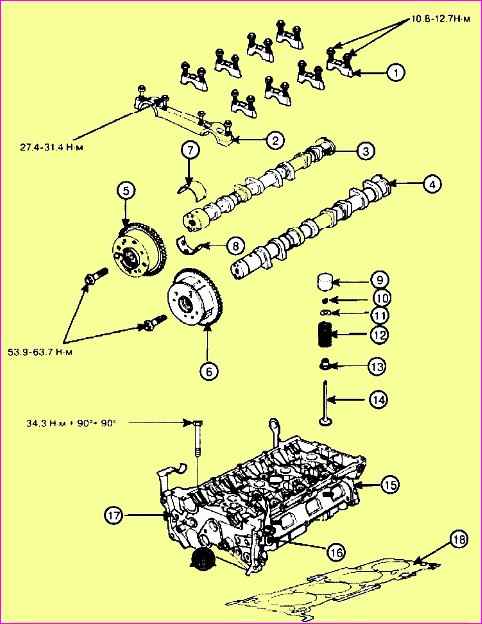

Using a hex wrench, install and tighten the 10 head bolts and washers in the order shown in the figure. Tightening torque: 34.3 Nm + 90˚ + 90˚.

Install the valves. Tightening torque: 9.8 - 11.8 Nm.

Do not damage or drop the valves.

Keep the filter clean.

When the valves are installed on the engine, do not move the engine while holding the valve bracket.

Install camshafts.

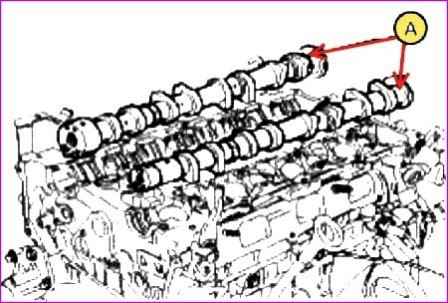

Apply a thin layer of engine oil to the camshaft bearings.

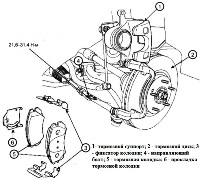

Install the lower exhaust camshaft bearing (A).

Install camshafts (A).

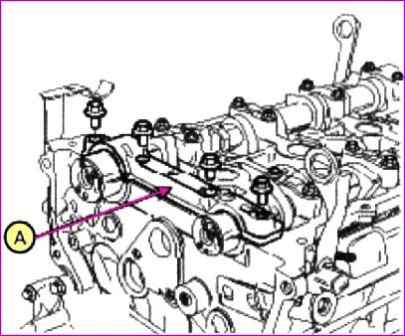

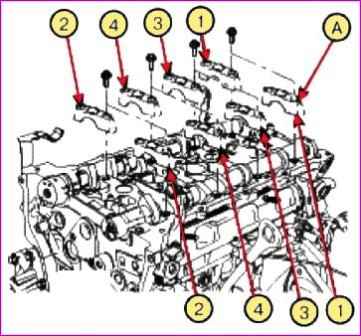

Install the upper exhaust camshaft bearing (A).

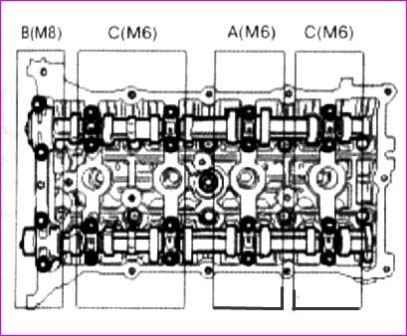

Install the bearing caps in their original position.

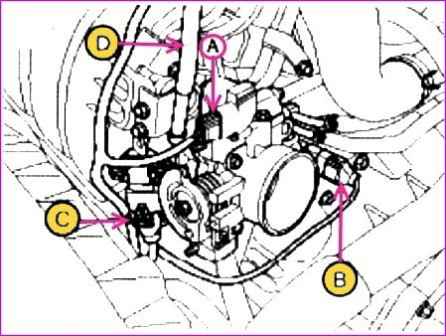

Torque order: group A -> group B - > group C.

Tightening torque:

- step 1: M6: 5.9 Nm, M8: 14.7 Nm,

- step 2: M6: 10.8 - 12.7 Nm, M8: 27.5 - 31.4 Nm.

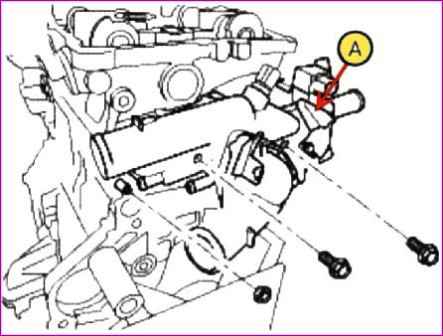

Install the thermostat assembly (A). Tightening torque for bolts and nuts: 18.6 - 23.5 Nm.

First install the thermostat assembly and the water inlet hose to the water pump, then tighten the inlet hose nuts.

Always use new O-rings.

Install the timing chain.

Check valve clearance.

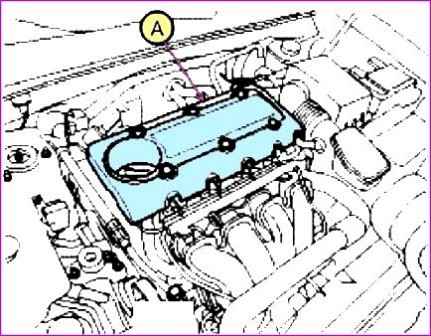

Install the cylinder head cover.

The hardened sealant located on the top surface between the chain cover and the head of the block must be removed before installing the head cover.

After applying sealant, assembly must be completed within 5 minutes. The thickness of the sealant strip is 2.5 mm.

Firing and blowing should be done no more than 30 minutes after installing the lid.

Install the cylinder head bolts as follows:

Tightening torque: step 1: 3.9 - 5.9 Nm, step 2: 7.8 - 9.8 Nm.

Do not reuse the cylinder head gasket.

Install intake and exhaust manifolds.

Connect the connectors of the positive crankcase ventilation hose (A), electronic ignition timing control (B), capacitor (C), crankshaft position sensor (D), camshaft position sensor (E), and brake booster vacuum hose.

p>

Connect the brake booster vacuum hose (D), the positive crankcase ventilation hose (C), the fuel hose (B), the camshaft position sensor (A).

Connect the connectors of the ETC and the absolute air pressure sensor (B).

Connect the connectors for the idle air control (A), throttle position sensor (B) and mass air flow sensor (C), then connect the throttle cable connectors (D).

Connect the injector connectors (A), throttle position sensor (B).

Connect the control valve connector (A).

Connect VIS(A), OPS(B), knock sensor (C) and compressor switch (D) connectors

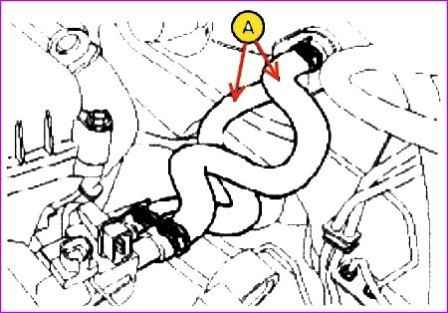

Install the heater hose (A).