In case of loss of power, increased fuel consumption or increased oil consumption, it is necessary to check the compression in the engine cylinders

Warm up and stop the engine to normal operating temperature.

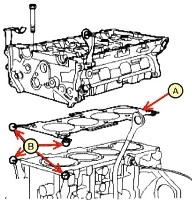

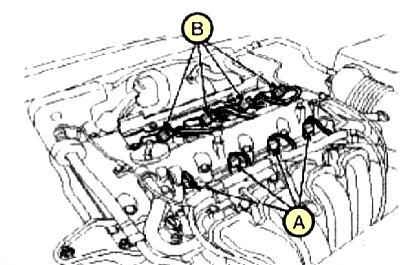

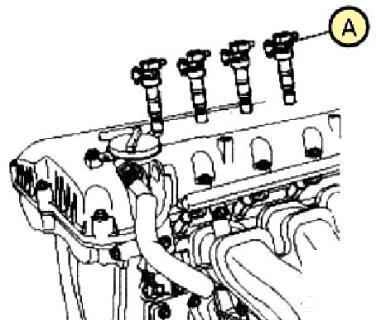

Disconnect ignition coil connectors (B) and injectors (A).

Remove nozzles (A)

Unscrew the spark plugs. Using a 16 mm special wrench, unscrew 4 candles.

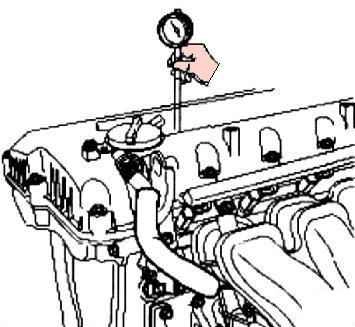

Check compression in each cylinder.

- - install the compression tester in the spark plug hole.

- - fully open the throttle.

- - cranking the crankshaft and starting the engine, measure the compression

Make sure the battery is fully charged to ensure 200 rpm.

Compression testing should be done in as little time as possible.

Repeat the above operations for each cylinder.

Standard compression value: 1.283 kPa.

Minimum allowable value: 1.135 kPa.

The difference between the compression of each of the cylinders: no more than 100 kPa.

If there is insufficient pressure in one or more cylinders, pour a small amount of engine oil through the spark plug hole into the cylinder and repeat steps 1 to 3.

If the compression has increased, then the compression rings are damaged or the piston has increased wear.

If the compression pressure has not changed, then the valve seats are probably damaged, or the valve does not sit properly.

It could also be a damaged cylinder head gasket.

Return the spark plugs.

Install ignition coils.

Connect the connector of the injector and the ignition coil.