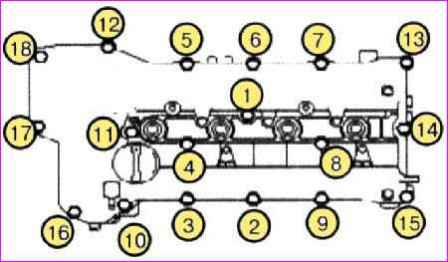

Removing the timing drive

Disconnect the negative cable from the battery.

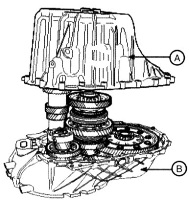

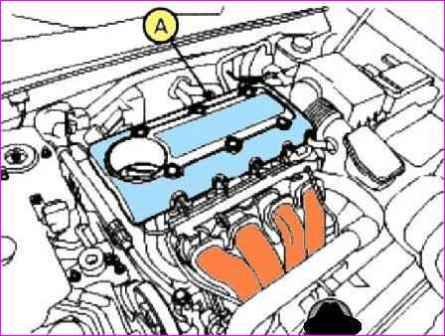

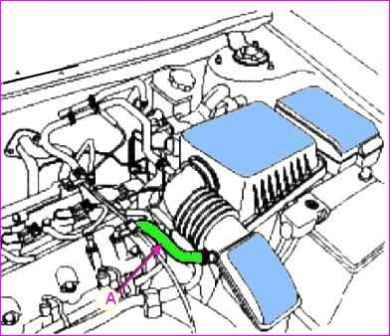

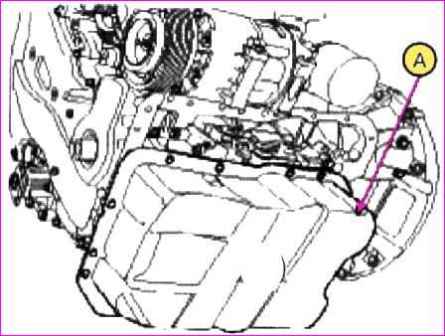

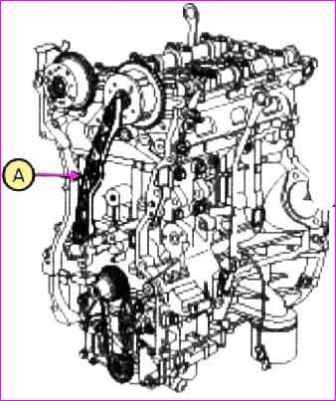

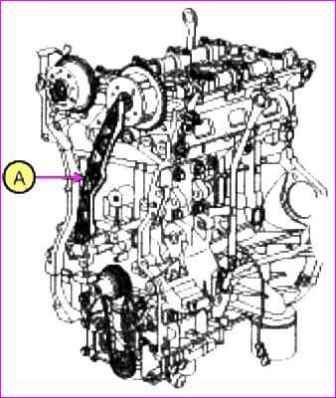

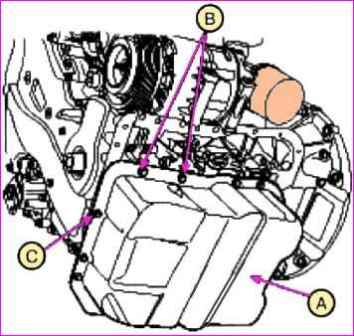

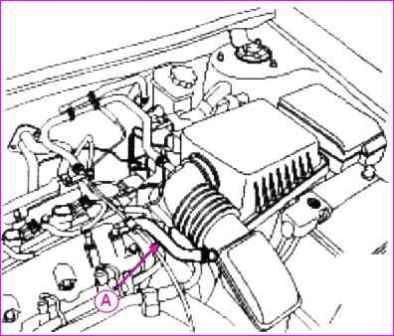

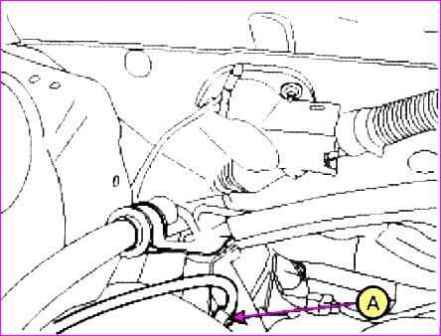

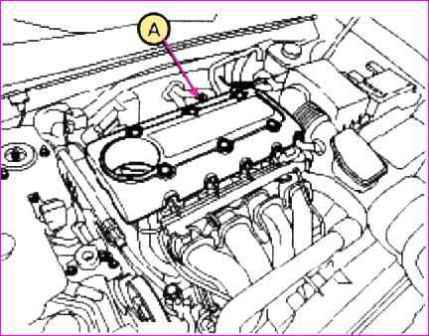

Remove the engine cover (A).

Remove the front right wheel.

Remove the side cover.

Set the piston of cylinder No. 1 to TDC/compression.

Drain the engine oil, then jack up the oil pan.

NOTE:

Install a wooden block - between the jack and the oil pan.

Remove the engine mount.

Remove the accessory drive belt.

Remove the pulley and the drive belt tensioner. (Left-hand thread idler pulley bolt)

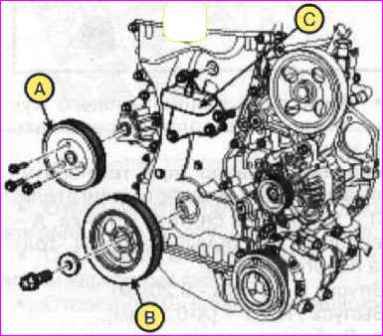

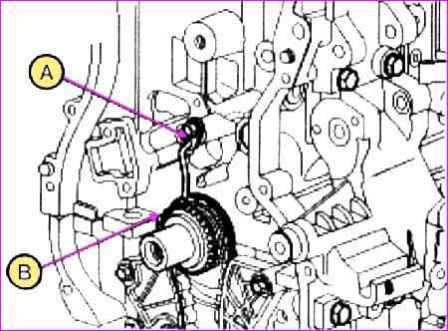

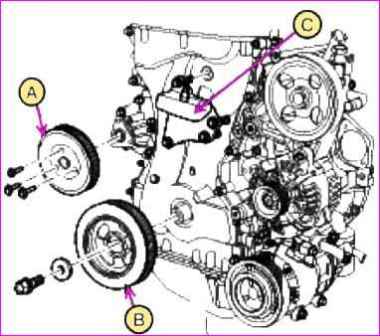

Remove the water pump pulley (A), crankshaft pulley (B), and engine support bracket (C).

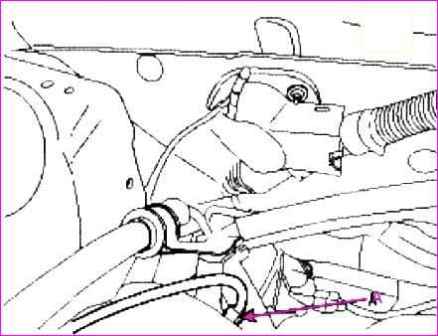

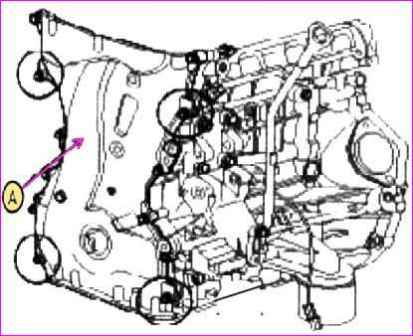

Disconnect the OSU cable connector (A).

Disconnect the ventilation hose.

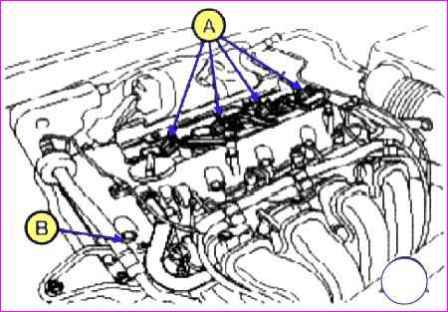

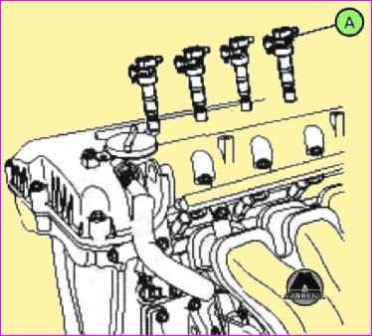

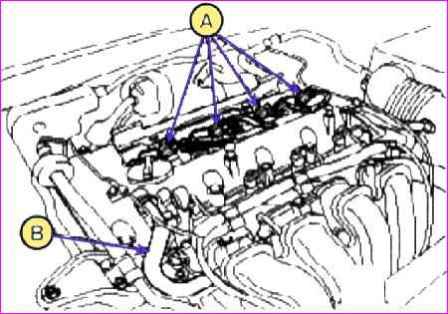

Disconnect the ignition coil connector (A) and the DCS hose (B).

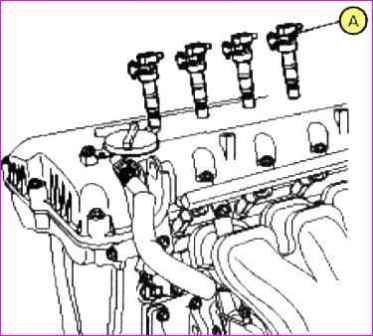

Remove the ignition coils.

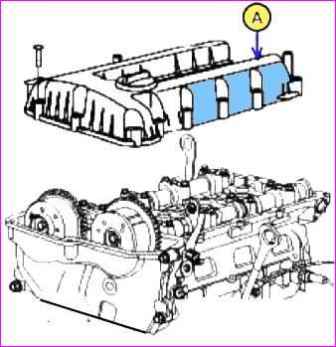

Remove the cylinder head cover

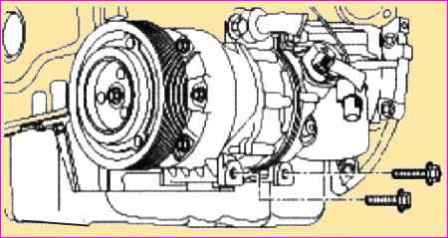

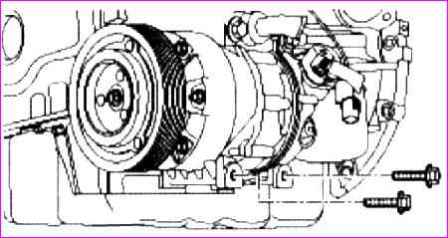

Remove the A/C compressor bottom bolts

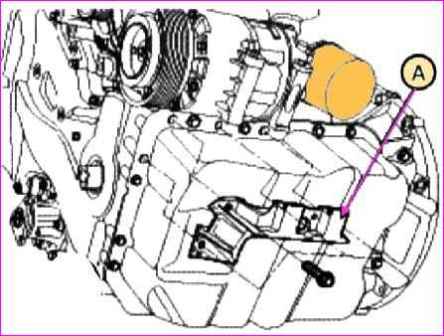

Remove the compressor mounting bracket.

Remove the mounting bolts and remove the oil pan.

Do not damage the contact surfaces of the cylinder block and oil pan.

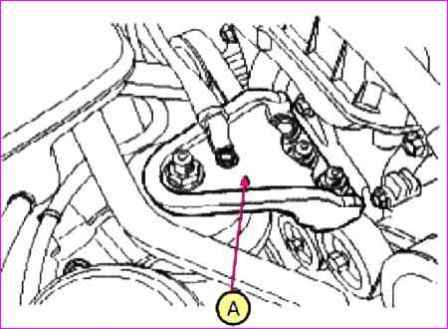

Remove the timing chain cover (A) carefully aligning between the head and the cylinder block.

Do not damage the contact surfaces of the cylinder block, cylinder head and timing chain cover.

The crankshaft key should be flush with the mating surface of the main bearing cap.

As a result, the piston of cylinder No. 1 will be at TDC, compression stroke.

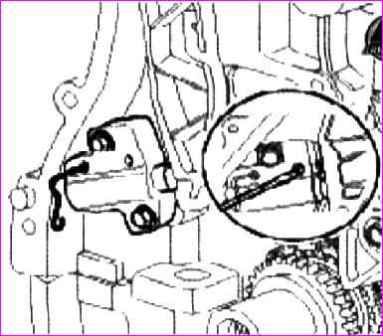

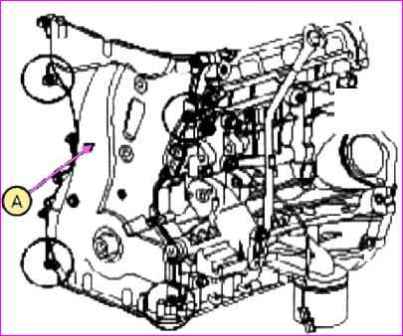

Install the locking pin after moving the chain tensioner rod into the housing as shown.

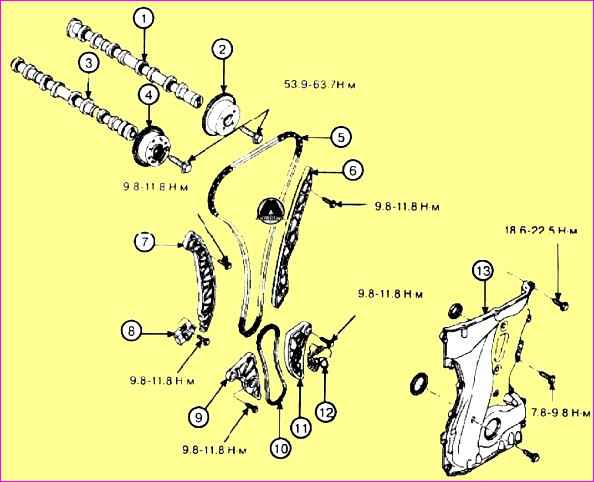

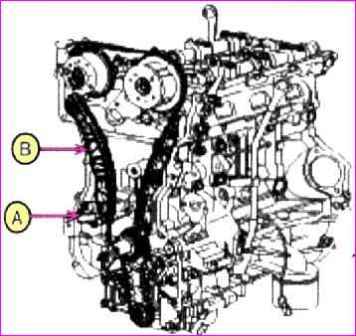

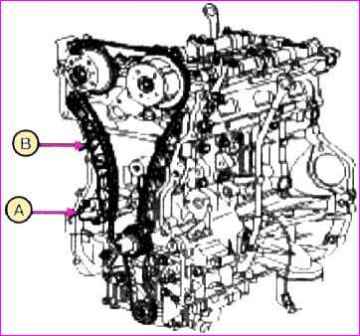

Remove the chain tensioner (A) and chain tensioner lever (B)

Remove the timing chain.

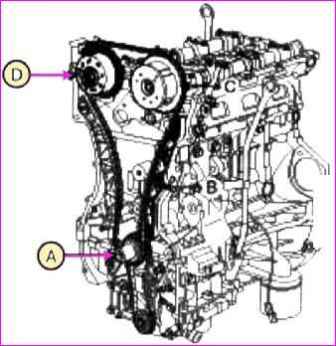

Remove the chain guide (A).

Remove the timing chain oil sprayer (A).

Remove the crankshaft drive chain sprocket (B).

Remove the balance shaft chain

Installing the timing drive

Install the crankshaft drive chain sprocket.

Install the chain oil sprayer (A) (see illustration above). Tightening torque 7.8 - 9.8 Nm.

Install the crankshaft so that the wrench is flush with the mating surface of the main bearing cap.

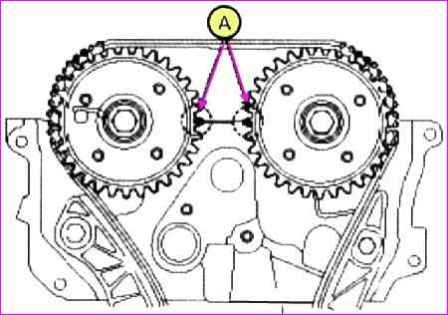

Position the intake and exhaust camshafts so that the TDC marks on the intake and exhaust sprockets are flush with the top surface of the cylinder head.

As a result, the position of the piston of cylinder No. 1 will be at TDC, compression stroke.

Install the timing chain guide (A). Tightening torque: 9.8 - 11.8 Nm.

Install the timing chain.

To install the chain without slack between each shaft (camshaft and crankshaft), follow the procedure:

Crankshaft sprocket (A) -> timing chain guide (B) -> CVVT intake sprocket assembly (C) -> CCVT release sprocket assembly (D).

The marks of each sprocket must match the marks of the timing chain (colored) when installing the chain.

Install the chain tensioner lever (B). Tightening torque 9.8 -11.8 Nm.

Install the timing chain auto-tensioner (A) and remove the installed stud. Tightening torque 9.8 - 11.8 Nm.

After turning the crankshaft 2 turns clockwise (front view), mark as shown.

Install the timing chain cover.

Using a gasket clip, remove the old material from the surface of the gaskets.

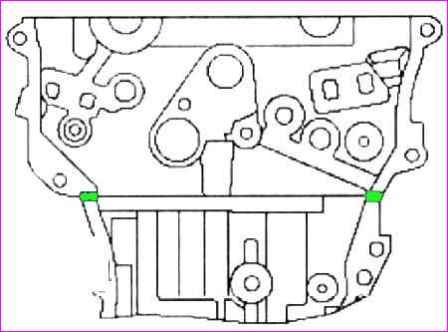

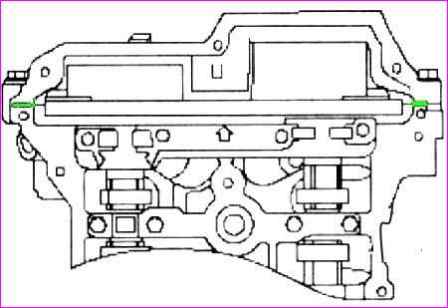

The sealing points on the chain cover, cylinder head, cylinder block and ladder frame must not come into contact with oil and ETC.

Before assembling the chain cover, liquid sealant must be applied to the gap between the head and the cylinder block.

Parts should be assembled within 5 minutes of sealant application. Band width 3 mm.

The timing pin of the cylinder block and the timing chain cover hole must be used according to the chain cover assembly order to be in the correct position. Tightening torque: M6 : 7.8 - 9.8 Nm, M8 : 18.6 - 22.5 Nm.

Firing and blowing the timing chain cover must be carried out no later than 30 minutes after assembly.

Install oil pan

Using a gasket scraper, remove the old material from the surface of the gaskets.

Before assembling the oil pan, a liquid sealant must be applied between the cylinder block and pan joint surfaces.

When applying sealant, be careful not to let the sealant get inside the oil pan.

After assembling, wait at least 30 minutes before filling the engine with oil.

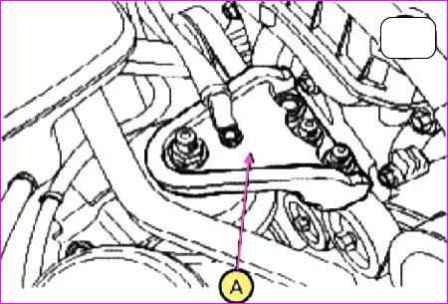

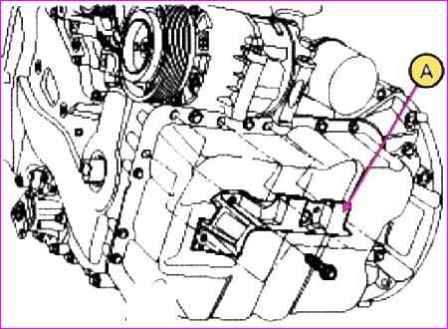

Install the compressor mounting bracket (A). Tightening torque: 19.6 - 23.5 Nm

Tighten the lower compressor mounting bolts. Tightening torque: 19.6 - 24.5 Nm.

Install the cylinder head cover.

Excess sealant extruded from the top surface of the chain cover and cylinder head must be removed prior to installing the cylinder head cover.

After applying the sealant, assembly must be completed within 5 minutes. Band width 2.5 mm.

The firing and blowing of the cylinder head must be carried out no later than 30 minutes after assembly.

Tighten the cylinder head cover bolts as follows:

- Step 1: tightening torque 3.9 - 5.95 Nm

- Step 2: Tightening torque 7.8 - 9.8 Nm

Do not reuse the cylinder head gasket

Install the ignition coils (A). Tightening torque: 3.9 - 5.9 Nm.

Connect the ignition coil connector (A) and hose

Connect the ventilation hose (A).

Connect the exhaust valve connector (A).

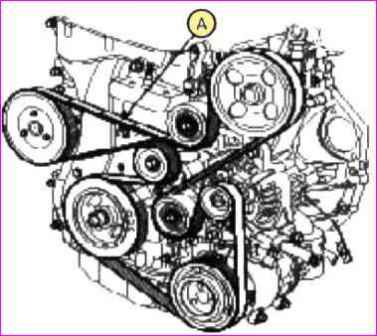

Install the engine mount bracket (C). Tightening torque: M10: 39.2 - 44.1 Nm, M8: 19.6 - 24,5 Nm.

Install the crankshaft pulley (B). Tightening torque: 166.6 - 176.4 Nm.

Use the flywheel retainer to install the crankshaft pulley bolt, then remove the starter.

Install the water pump pulley (A). Tightening torque: 7.9 - 9.8 Nm.

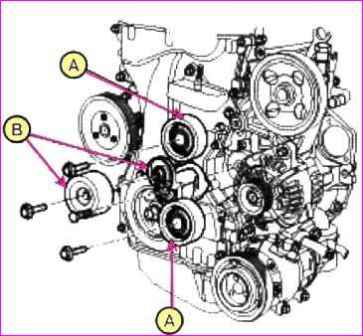

Install the drive tensioner (B). Tightening torque: 63.7 Nm.

NOTE:

Left-hand thread tensioner pulley bolt.

Install the roller (A). Tightening torque: 53.9 - 63.7 Nm.

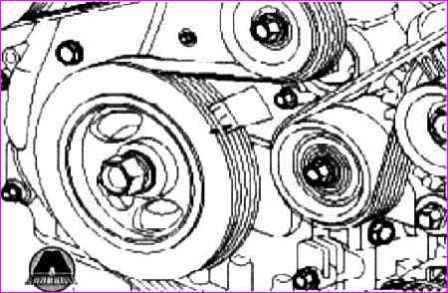

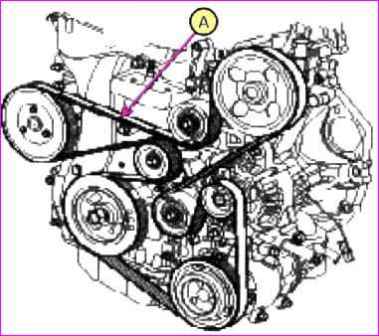

Install the drive belt (A) like this:

Crankshaft pulley -> air conditioner pulley -> alternator pulley ->roller pulley -> power steering pump pulley -> roller pulley -> water pump pulley -> tensioner pulley.

Rotate the auto-tensioner lever clockwise while moving the auto-tensioner bolt with a wrench.

Install the engine mount bracket (A). Tightening torque: 63.7 - 83.4 Nm.

Install the side cover. Tightening torque: 8.8 - 10.8 Nm.

Install the front right wheel. Tightening torque: 88.3 - 107.9 Nm.

Replace the engine cover (A).

Connect the negative cable to the battery.

Checking the technical condition of timing parts

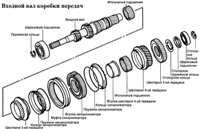

Sprockets, hydraulic tensioner, chain guide and tensioner arm

Check the camshaft and crankshaft drive sprocket teeth for excessive wear, chipping, and breakage. If necessary, replace the sprockets with new ones

Inspect the chain contact surface at the tensioner arm and guide for excessive wear and damage. If necessary, replace with new ones.

Check the stroke of the hydraulic tensioner plunger and the smoothness of its movement.

If any defects are found, replace the tensioner assembly.

Accessory drive belt and pulleys

Check the intermediate pulley for oil contamination, as well as for excessive wear and damage.

If defects are found, replace with a new one.

Check the drive belt for excessive wear. If necessary, replace with a new one.

Check the pulleys for vibration while rotating. If necessary, replace the pulley with a new one.