We remove the gearbox during partial or complete repairs, also when replacing the clutch mechanism

We work together on the inspection ditch

Be careful, the box weighs about 32kg!

Drain the oil (see How to change the oil in the gearbox of a Gazelle car).

Disconnect the driveline from the gearbox (see Inspection and removal of the driveshaft of the Gazelle car).

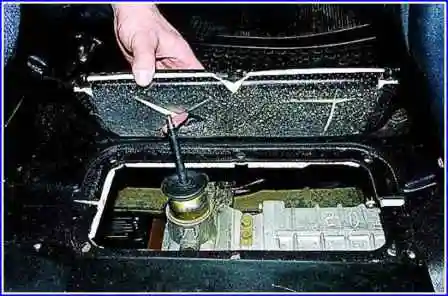

From the cab, prying with a slotted screwdriver, we raise the corrugated cover of the gear lever

Use a screwdriver or a beard to pry off the locking sleeve.

Remove the upper part of the lever together with the cover.

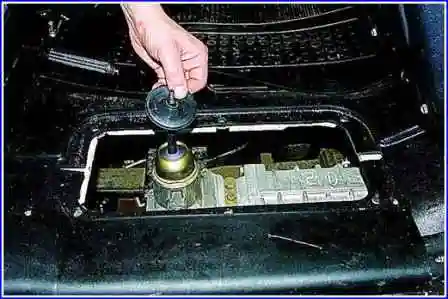

We open the sectors of the spacer sleeve with two screwdrivers, and remove the sleeve

Remove the rubber cushion

Remove the locking sleeve

For the convenience of subsequent assembly, we install the parts of the upper arm into its inner cavity in the reverse order of removal and fix them with a locking sleeve.

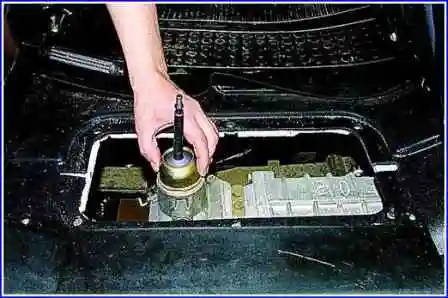

Use a screwdriver to unscrew six screws

Remove the floor seal.

Remove the protective cover.

Turn off the cap with your hand or pliers

Remove the lever

From the bottom of the car, disconnect the speedometer drive cable and the wires of the reverse light switch from the gearbox.

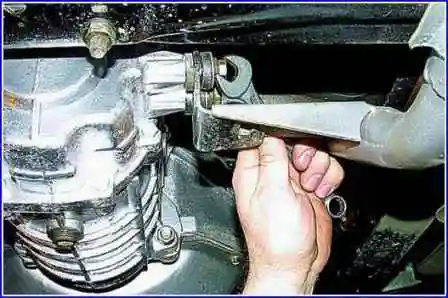

Holding the bolt of fastening of the receiving pipes with the key "12", with the key "14" unscrew its two nuts.

Using the “14” key, we unscrew the two bolts securing the bracket to the gearbox.

Remove the bracket together with the rubber washers.

Using the “19” key, we unscrew the four nuts securing the gearbox to the clutch housing.

We install an emphasis under the power unit or put a bar between the head of the block and the shield of the engine compartment

We unscrew the two nuts securing the gearbox to the cross member and remove the cross member.

Carefully rocking and shifting the box back, remove it.

We install the gearbox in the reverse order, lubricating the splines of the input shaft with SHRUS-4 grease.