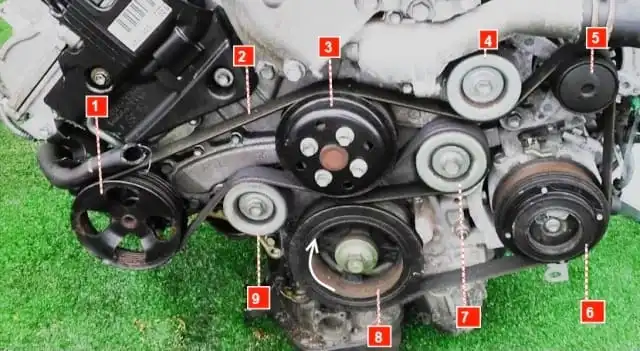

Auxiliary units: generator, water pump, power steering pump and air conditioning compressor of the 2GR-FE engine are driven by a V-ribbed belt

Constant tension is ensured by the automatic tensioner

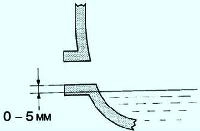

The tension of the auxiliary drive belt is checked by pressing a finger on the belt branch between the pulleys of the water pump and the power steering pump

When pressed with a force of 100 N (10 kgf), the belt deflection should be 4-6 mm.

If the belt is loose, the automatic tensioner must be replaced

The belt should be replaced if it is cracked, the ribs are missing, or the belt is worn to the point where the fibers are exposed

To replace the belt you need:

Remove the decorative engine cover

Remove the right front wheel

Remove the right front wheel liner

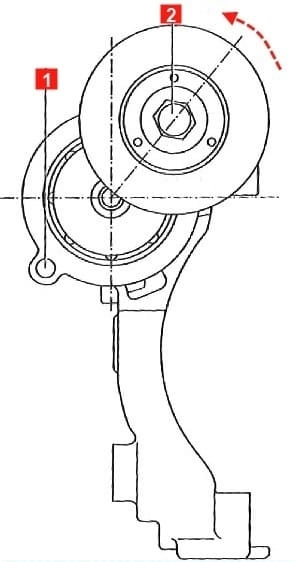

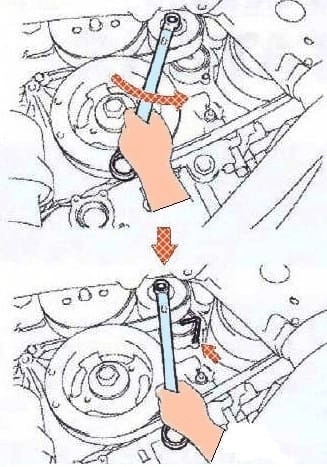

Putting the wrench on the hexagon 2 of the tensioner roller axis, turn the tensioner lever in the direction indicated by the arrow until hole 1 in the lever aligns with the hole in the tensioner bracket

We fix the tensioner lever in this position by inserting a rod of a suitable diameter into the holes (you can insert a 5 mm hex wrench)

Remove the accessory drive belt

Installing the new belt

Turn the poly V-belt tensioner counterclockwise and remove the retainer from the holes

Turn the crankshaft three turns and make sure that the belt is in the correct position in the pulley streams

Install all removed parts in reverse order