External signs of the need to remove bearings for troubleshooting are:

- – increased noise during wheel rotation;

- - the impossibility of adjusting to achieve the nominal clearance in the bearings.

You will need: a wrench for wheel nuts, a hammer, a screwdriver, wrenches "for 13", "for 17", a torque wrench, firmware (beard), a mandrel for pressing the stuffing box, kerosene, Litol-24 grease, a container for washing parts .

We carry out work on a viewing ditch or a lift.

Hang out the front of the car and remove the wheel.

Disconnect the caliper from the pad guide and tie them with wire to the upper arm.

We unscrew the adjusting nut of the hub bearings (see Checking and adjusting the clearance in the hub bearings).

Remove the taper bushing.

With a chisel, we unbend the edge of the locking plate of the nut of the front fastening of the lever to the steering knuckle.

Similarly, unlock the rear fastening nut.

Using a 19 spanner wrench, unscrew the nut of the rear fastening of the lever to the steering knuckle.

Similarly, unscrew the front fastening nut.

Remove the lock plate.

Having removed the lever from the bolts, we take it away from the steering knuckle.

Disconnect the brake hoses from the steering knuckle.

Disconnect the fastening of the upper and lower ball joints from the levers (see Removing the upper ball joint, and Removing the lower ball joint).

Remove the steering knuckle assembly with ball bearings, hub assembly and brake disc from the splines of the front wheel drive outer hinge housing.

Disconnect the steering knuckle and the hub with the brake disc.

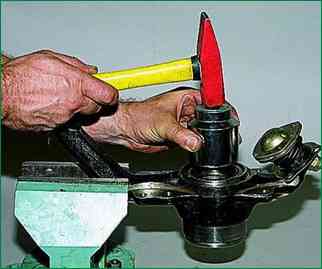

If it is difficult to separate the parts, we clamp the steering knuckle in a vise and knock out the hub with a soft metal drift

Now you can remove the bolts securing the lever to the steering knuckle

To separate the hub and the brake disc, screw the nut onto the stud and knock out the stud

Having unscrewed the nut, we take out the stud. Dismantle other studs in the same way

Disconnect the hub and the brake disc.

We use a chisel to knock down the dirt ring.

Use the key "10" to unscrew the bolt securing the protective cover

Remove the cover

To dismantle the oil seals and hub bearings, we clamp the steering knuckle in a vise.

Pry off the gland with a screwdriver and take it out.

Retrieve the ring.

We take out the inner ring of the outer bearing with the cage and rollers.

Similarly, we take out the oil seal, ring and inner ring of another (inner) bearing with a cage and rollers

With a beard we knock out the outer ring of the outer bearing and take it out.

Similarly, we knock out the outer ring of the inner bearing.

We assemble in the reverse order.

Before installing the bearings, we clean the inner cavity of the steering knuckle from old grease.

We press in the outer rings of the bearings with a suitable piece of pipe.

We put 40 g of Litol-24 grease into the cavity of the steering knuckle and into the bearing separators.

We press the seals with a suitable piece of pipe.

By installing the dirt a solid ring, with a chisel we press the metal of the ring into the groove of the steering knuckle in several places.

Having connected the brake disc to the hub, we press in the studs with a soft metal drift

The stud heads with the milled surface should face the cylindrical surface of the brake disc.

So that the bolts securing the lever to the steering knuckle do not fall out when it is installed on the car, we screw nuts on them.

Having inserted the shank of the outer joint of the drive into the splines of the hub, we mount the steering knuckle

At the end of the assembly, we adjust the clearance in the bearings (see Checking and adjusting the clearance in the hub bearings)