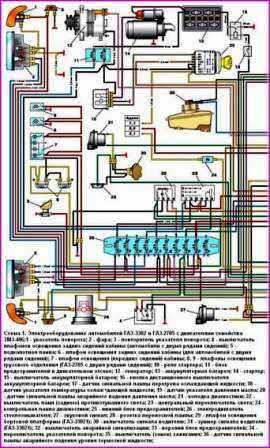

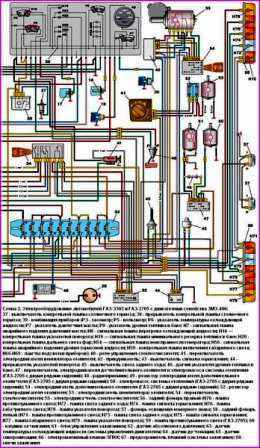

The scheme for a more detailed study consists of two parts

Electrical equipment failures are due to the simplest causes, such as corrosion of connector contacts, fuse failure, fuse blown, or relay damage

Visually check the condition of all fuses, wiring, and connectors in the circuit before proceeding to a more detailed check of the health of its components.

When using diagnostic tools for troubleshooting, carefully plan (in accordance with the attached electrical diagrams) where and in what sequence the device should be connected in the loop for the most effective troubleshooting.

The main diagnostic tools include an electrical circuit tester or voltmeter (you can also use a 12-volt test lamp with a set of connecting wires), an open circuit indicator (probe) that turns on the lamp with its own power source and a set of connecting wires.

In addition, you should always have a set of wires in the car for starting the engine from an external power source (the battery of another car), equipped with crocodile clips.

As already mentioned, before starting to check the circuit using diagnostic equipment, determine the connection points from the diagrams.