If oil leakage is detected from under the front crankshaft oil seal, it must be replaced

Before replacing the oil seal, make sure that the crankcase gas recirculation system is not clogged

Rinse crankcase ventilation parts (oil separator, hose).

Of course, if the car has a high mileage and its overhaul is already suitable, then the oil seal is easier to replace with the engine removed during the repair.

Let's consider replacing the oil seal when the engine is on the car.

We install the car on a viewing ditch or on a lift.

Remove the mudguards of the engine compartment.

Remove the radiator of the engine cooling system.

After that, from the bottom of the car with a 13 key, unscrew the two bolts securing the spacer of the radiator frame to the lower cross member of the frame

With a 13 head, we unscrew the two bolts securing the spacer to the radiator frame amplifier

We unscrew the two bolts securing the spacer to the upper cross member of the radiator frame

Squeezing the antennae of the wire harness holder with pliers, remove the wire harness holder from the spacer hole and remove the radiator frame spacer.

Without the radiator frame spacer, it is more convenient to dismantle the accessory drive belts.

Remove the crankshaft position sensor so as not to damage it. To do this, disconnect the block of wires from the sensor

Use a Phillips screwdriver to unscrew the sensor mounting screw

Remove the sensor from the tide hole of the timing cover

Remove the drive belts for the air conditioning compressor and auxiliary drive.

We turn on the fifth gear of the gearbox and brake the wheels with a hand brake.

With a 38 head, unscrew the pulley fastening nut

Finally unscrewing the nut

Remove the pulleys from the toe of the crankshaft

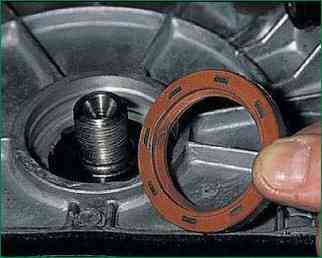

Pry off m screwdriver gland

Remove it from the socket of the timing cover

Having lubricated the working edge of the oil seal with engine oil, we press the oil seal with a suitable tool head or a piece of pipe

If you need to disconnect the drive pulleys:

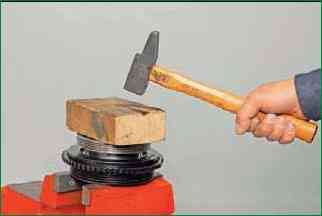

Installing the pulleys on the extended vise

Through the holes in the pulley, evenly using a drift and a hammer, we strike at the end of the air conditioning compressor pulley

Disconnecting the pulleys

We press the drive pulleys with a wooden spacer