Removing the crankshaft

Remove the oil sump and crankcase gasket.

Remove the oil pump.

Remove the fan drive belt.

Remove the alternator drive belt.

Remove the sprocket cover.

Install the piston of the 1st cylinder at TDC. compression stroke.

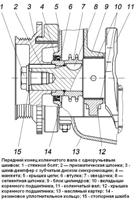

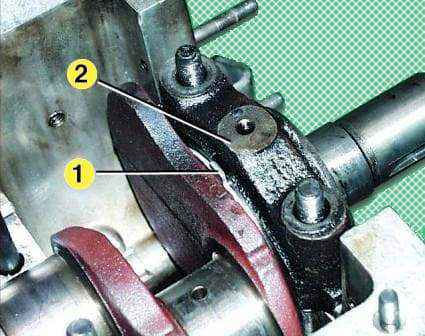

Using a puller, press the sprocket 1 off the end of the crankshaft. Remove thrust washer 2.

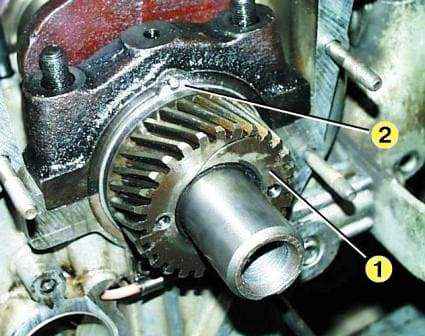

Unscrew the four nuts 1, having previously bent the edges of the locking plates 2, and remove the flywheel 3, removing it from the bottom of the clutch housing.

If you do not need to remove the pistons from the cylinders, you can not remove the cylinder head, just unscrew the nuts of the connecting rod bolts, remove the connecting rod caps and carefully slide the pistons into the cylinders.

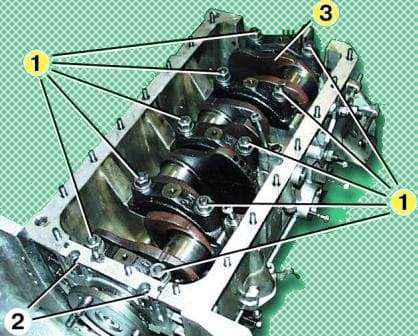

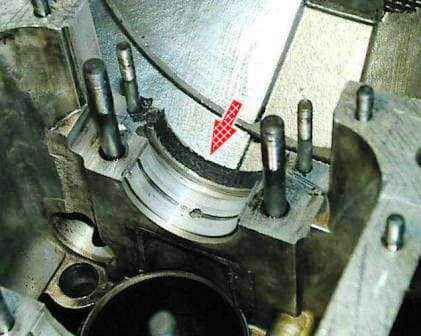

Remove nuts 1 and bolts 2 and remove main bearing caps.

Since the lids are tight, knock them down with gentle hammer blows.

Remove the crankshaft 3 from the main bearing beds.

Remove the second thrust washer from the end of the crankshaft.

Remove the main bearing shells from the main bearing beds and caps.

It is easier to remove the liners if you move them with a screwdriver so that the end of the liner protrudes above the edge of the bed.

Crankshaft troubleshooting and repair

Rinse all parts with gasoline and dry.

Inspect the crankshaft. If it has cracks, it must be replaced.

Remove the plugs, clean, rinse with gasoline and blow out the crankshaft oil channels with compressed air.

Put on the plugs and tighten to 38–42 Nm (3.8–4.2 kgf m).

If there are minor marks on the main and connecting rod journals, scratches, scuffs, or the ovality of the journals exceeds 0.01 mm, the journals must be ground to the repair size.

After grinding, the necks must be polished.

Brush the sharp edges of the chamfers of the oil channels with an abrasive cone.

After grinding, rinse the shaft and blow out the oil passages with compressed air.

After grinding the crankshaft journals, it is necessary to install the main and connecting rod bearing shells of the appropriate repair size.

Inspect the main bearing shells.

If they have marks, scuff marks, scratches, delaminations, inclusions of solid particles, etc., replace the liners.

Inspect the flywheel.

If the teeth of the flywheel crown are damaged, there are scuffs, scratches, etc. on the surface adjacent to the clutch disc, replace the flywheel.

If the flywheel is cracked, it should also be replaced.

In the hole of the crankshaft on the flywheel side, the input shaft toe bearing, closed type, is pressed in.

Inspect the bearing, if defects are found (large play, jamming, damage to protective rings, etc.), press it out of the crankshaft using a puller.

Press the new bearing flush with the bottom edge of the chamfer of the hole in the crankshaft.

Inspect the crankshaft oil seal in the camshaft cover.

If the oil seal is damaged (tears, tears, heavy wear of the working edge, etc.), it must be removed from the cover with a screwdriver and a new one must be pressed in.

If the vehicle has a high mileage, it is recommended to replace the oil seal.

Replace the packing of the rear crankshaft seal in bed main bearing and in the holder.

Remove the old packing and put in a new one about 120 mm long.

Cut the ends of the stuffing so that it protrudes 0.5–1.0 mm above the plane of the bed and the holder.

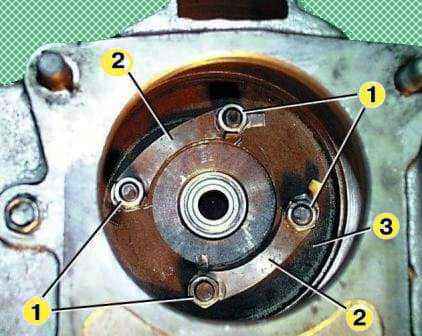

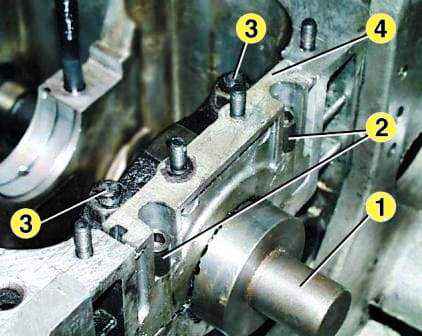

Compress the packing, to do this, put a mandrel 1 in the bearing bed, install the holder 4 and the main bearing cover and tighten the nuts 3 and bolts 2.

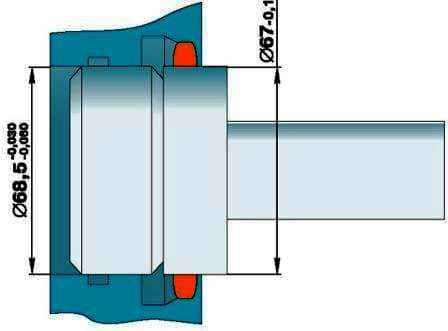

The dimensions of the mandrel are shown in the figure.

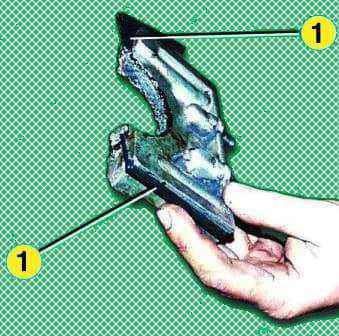

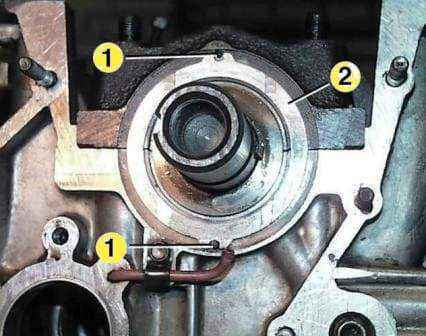

Check the condition of the rubber seals 1 in the stuffing holder.

If they have lost their elasticity, cracked, torn, etc., the seals must be replaced.

Installing the crankshaft

Install the crankshaft in the reverse order of removal, taking into account the following:

Before installing, lubricate the crankshaft main and connecting rod journals, main bearing shells and thrust washers with engine oil and put the rear thrust washer on the front end of the crankshaft with an anti-friction layer against the crankshaft web.

When installing the cover 2 of the first main bearing, the protrusion of the rear thrust washer 1 must fit into the groove of the cover 2.

Install front thrust washer 2 on pins 1, anti-friction layer facing out.

The spacer between the crankshaft gear and the front thrust washer is installed with a chamfer in the hole towards the thrust washer.

After installing the crankshaft gear, measure its axial clearance, which should be between 0.125–0.325 mm.

The gap is measured between the end of the rear thrust washer and the crankshaft web, while the shaft must be pressed to the limit towards the flywheel.

Tighten the nuts of the main bearing caps to a torque of 100–110 Nm (10–11 kgf m), while applying Unigerm-9 sealant to the threads of the nuts.

Tighten the flywheel mounting nuts to a torque of 76–83 Nm (7.6–8.3 kgf m) and lock by bending the edge of the locking plate onto the face of the nut.

Crank the crankshaft before connecting the connecting rods. It should rotate easily, without jamming.