Interpreting states

ET018 - Request to turn on the air conditioner

Diagnostic hints

There must be no current or stored faults.

The ECM does not "see" the request to turn on the A/C.

Using a universal contact board, check for an open and short circuit in the circuit:

-ECU, terminal "46" - terminal "5" of the air conditioning control unit.

Troubleshoot if necessary.

If the problem persists, diagnose the air conditioning system.

Repeat conformity check after troubleshooting.

ET054 - Idle speed control

Diagnostic hints

There must be no current or stored faults.

Pay attention to the correspondence between parameters PR145 Engine speed and PR190 Idling speed setpoint.

Check the connection and condition of the idle speed control connector.

Troubleshoot if necessary.

Measure and compare the value of the resistance of the idle speed control stepper motor with the value given in the article Diagnostic codes and troubleshooting methods for the ECM Lada Largus "Additional information".

Replace the idle speed control if necessary.

Using a universal contact board, check for an open and short circuit in the circuit:

- - ECM, terminal "12" - terminal "B" of the idle speed control;

- - ECU, terminal "41" - terminal "A" of the idle speed control;

- - ECU, terminal "42" - terminal "C" of the idle speed control;

- - ECU, terminal "72" - terminal "D" of the idle speed control.

Troubleshoot if necessary.

At low idle, check:

- - operation of the fuel mixture composition control system;

- - check the air supply system for contamination;

- - engine oil level

- - clearances in the valve drive mechanism and setting the valve timing;

- - ignition system (see p. Additional information in the article Diagnostic codes and troubleshooting methods for ECM Lada Largus);

- - injectors;

If no remarks are found, replace the idle speed control.

If the idle speed is too high, check:

- - engine oil level;

- - operability of the absolute pressure sensor;

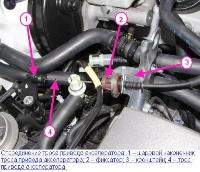

- - state of the hoses connected to the intake manifold;

- - condition of the intake manifold gaskets;

- - condition of the throttle pipe gaskets;

- - tightness of the vacuum brake booster;

- - the presence of calibration jets in the crankcase ventilation system;

- - gaps in the valve drive mechanism and the setting of the gas distribution phases.

If no remarks are found, replace the idle speed control.

Repeat conformity check after troubleshooting.

ET297 - Pressure sensor in the power steering system

Diagnostic hints

There must be no current or stored faults.

Perform this interpretation only if the result of the conformity check is negative.

Check the reliability of the connection and the condition of the pressure sensor connector in the power steering system.

Troubleshoot if necessary.

Using a universal contact board, check for an open and short circuit in the circuit:

- - ECM, pin "85" - pin "1" of the pressure sensor in the power steering system;

- - "ground" - contact "2" of the pressure sensor in the power steering system.

Troubleshoot if necessary.

If the problem persists, replace the pressure sensor in the power steering system.

Repeat conformity check after troubleshooting.

ET298 - Low speed electric fan of the engine cooling system

Diagnostic hints

There must be no current or stored fault in the coolant temperature sensor circuit.

Check:

- - electric fan ground circuit;

- - power circuit between the electric fan and the electric fan resistor;

- - power circuit between the electric fan resistor and contact "A5" of the electric fan low speed relay.

Troubleshoot if necessary.

Check the reliability of the connection and the condition of the block to the low speed electric fan relay.

Troubleshoot if necessary.

Check for the presence of 12 V voltage on the contact "A3" of the electric fan low speed relay.

If necessary, repair the fault in the circuit up to the fuse.

Check with the ignition on the presence of 12 V voltage on the contact "A1" electric fan low speed relay.

If necessary, eliminate the malfunction in the circuit up to contact "A5" of the relay of actuators.

Check the low speed relay winding for an open circuit.

Replace the relay if necessary.

Using a universal contact board, check for an open and short circuit in the circuit:

-ECU, terminal "8" - terminal "A2" of the low speed fan relay.

Troubleshoot if necessary.

Repeat conformity check after troubleshooting.

ET299 - High speed electric fan of the engine cooling system

Diagnostic hints

There must be no current or stored fault in the coolant temperature sensor circuit.

Check:

- - electric fan ground circuit;

- - power supply circuit between the electric fan and contact "5" of the high speed relay of the electric fan.

Troubleshoot if necessary.

Check the reliability of the connection and the condition of the block to the high speed relay of the electric fan.

Troubleshoot if necessary.

Check for the presence of 12 V on pin "3" of the high speed fan relay.

If necessary, repair the fault in the circuit up to the fuse.

Check, with the ignition on, the presence of 12 V voltage on pin "1" of the high speed electric fan relay.

If necessary, eliminate the malfunction in the circuit up to contact "A5" of the relay of actuators.

Check the winding of the high speed relay of the electric fan for an open circuit.

Replace the relay if necessary.

Using a universal contact board, check for an open and short circuit in the circuit:

- ECU, terminal "38" - terminal "2" of the high speed fan relay.

Troubleshoot if necessary.

Repeat conformity check after troubleshooting.

ET300 - Regulation of the composition of the working mixture

Diagnostic hints

There must be no current or stored faults.

Check the connection and condition of the upstream oxygen sensor connector.

Troubleshoot if necessary.

Check:

- - ignition system (see p. Additional information in the article Diagnostic codes and troubleshooting methods for ECM Lada Largus);

- - tightness of the exhaust system;

- - tightness of the intake manifold;

- - fuel pressure.

If the engine is unstable at idle, check the clearances in the valve drive mechanism and the valve timing.

Troubleshoot if necessary.

With the ignition on, check for 12 V voltage on track "4" of the harness block to the upstream oxygen sensor.

If necessary, troubleshoot the circuit up to the actuator relay.

Perform an Oxygen Sensor Diagnostic Test (Oxygen Sensor Diagnostics, p.)

Replace the oxygen sensor if necessary.

Using a universal contact board, check for open and short circuits in the circuits:

- - ECU, terminal "45" - terminal "2" of the upstream oxygen sensor;

- - ECU, terminal "80" - terminal "1" of the upstream oxygen sensor.

Troubleshoot if necessary.

Repeat conformity check after troubleshooting.

ET321 - A/C compressor

Diagnostic hints

There must be no current or stored faults.

Using a universal contact board, check for an open and short circuit in the circuit:

- ECU, terminal "10" - terminal "B2" of the air conditioning compressor relay.

Troubleshoot if necessary.

If the problem persists, diagnose the air conditioning system.

Repeat conformity check after troubleshooting.

Parameter interpretation

PR058 - Air temperature

Diagnostic hints

There must be no current or stored faults.

If the temperature value read by the device does not correspond to the actual value, check that the resistance of the sensor changes with temperature.

Compare the resistance values of the sensor with the values given in the article "Diagnostic codes and troubleshooting methods for ECM Lada Largus "Additional information".

If necessary, replace the air temperature sensor.

Using a universal contact board, check for open and short circuits in the circuits:

- - ECU, terminal "49" - terminal "1" of the air temperature sensor;

- - ECM, terminal "77"- contact "2" of the air temperature sensor.

Troubleshoot if necessary.

Repeat conformity check after troubleshooting.

PR064 - Coolant temperature

Diagnostic hints

There must be no current or stored faults.

If the temperature value read by the device does not correspond to the actual value, check that the resistance of the sensor changes with temperature.

Compare the sensor resistance values with the values provided in the Lada Largus ECM Diagnostic Codes and Troubleshooting "More Information" article.

If necessary, replace the coolant temperature sensor.

Using a universal contact board, check for open and short circuits in the circuits:

- - ECU, terminal "13" - terminal "B1" of the coolant temperature sensor;

- - ECU, terminal "73" - terminal "B2" of the coolant temperature sensor.

Troubleshoot if necessary.

Repeat conformity check after troubleshooting.

PR071 - ECU supply voltage

Diagnostic hints

There must be no current or stored faults.

When the ignition is on

If the supply voltage is less than the minimum allowable value, then the battery is discharged:

- check the battery charging circuit.

If the supply voltage is greater than the maximum allowable value, then the battery charge voltage is over the allowable range:

- check the battery charge voltage both when the power consumers are turned off and on.

Idling

If the supply voltage is less than the minimum allowable value, then the battery charge voltage is less than the allowable range:

- check the battery charging circuit.

If the supply voltage is greater than the maximum allowable value, then the battery charge voltage is over the allowable range:

- check the generator voltage regulator.

If the battery and charging circuit are OK, refer to the interpretation of fault DF587 "+5 V sensor supply voltage".

Repeat conformity check after troubleshooting.

PR139 - Adaptive correction of the composition of the working mixture in load conditions

PR140 - Adaptive idle mixture control

Diagnostic hints

There must be no current or stored faults.

Programming of the adaptive mixture correction parameters must be completed:

- to perform this programming, it is necessary to carry out a road test, observing the required pressure ranges in the intake manifold (see paragraph "Adaptive mixture correction").

Check the canister purge circuit for leaks.

Troubleshoot if necessary.

Check these parameters on a running warm engine when adjusting idle speed:

- - if one of these parameters approaches its maximum value, then this indicates a lack of fuel or excess air;

- - if one of these parameters approaches its minimum value, then this indicates an excess of fuel or a lack of air.

Check:

- - fuel filter and fuel pump for contamination;

- - fuel injectors for contamination;

- - air intake system for suction and limited patency;

- - air filter for pollution.

Fix comments, if necessary.

Check:

- - compression in the engine cylinders;

- - gaps in the valve drive mechanism;

- - ignition system (see p. "Additional information").

Fix comments, if necessary.

Repeat conformity check after troubleshooting.

PR421 - Intake manifold pressure

Diagnostic hints

There must be no current or stored faults.

If the manifold pressure value read by the gauge does not correspond to the actual value, or if the manifold pressure value is less than the minimum pressure at idle, use the universal contact board to check for an open or short circuit in the circuits:

- - ECU, terminal "15" - terminal "A" of the absolute pressure sensor;

- - ECU, terminal "16" - terminal "B" of the absolute pressure sensor;

- - ECM, terminal "78" - terminal "C" of the absolute pressure sensor.

Troubleshoot if necessary.

If the problem persists, replace the MAP sensor.

If the manifold pressure read by the gauge is greater than the maximum idle pressure, check:

- - tightness of the sensor mounting absolute pressure on the intake manifold;

- - gaps in the valve drive mechanism;

- - compression in the engine cylinders;

- - lack of air leakage in the intake manifold;

- - no restriction on the patency of the exhaust gas system.

Troubleshoot if necessary.

If the problem persists, replace the MAP sensor.

Repeat conformity check after troubleshooting.

PR429 - Measured throttle position

Diagnostic hints

There must be no current or stored faults.

Throttle position "idle" (status ET278) or throttle position "full load" (status ET279) is not detected.

Check the position of the throttle position sensor mechanical stop.

Check the throttle cable for signs of friction, binding.

Troubleshoot if necessary.

Check that the resistance of the sensor changes smoothly when moving the throttle from the "idle" position to the "full load" position.

Replace the throttle position sensor if necessary.

Using a universal contact board, check for open and short circuits in the circuits:

- - ECU, terminal "43" - terminal "C" of the throttle position sensor;

- - ECU, terminal "74" - terminal "B" of the throttle position sensor;

- - ECM, terminal "75" - terminal "A" of the throttle position sensor.

Troubleshoot if necessary.

Error in parameter PR429 Throttle position measured.

Check the mechanical connection of the sensor with the throttle valve.

Troubleshoot if necessary.

Repeat conformity check after troubleshooting.

Command Interpretation

Command / Name

- AC015 Fuel pump relay

- AC017 Canister purge solenoid valve

- AC018 Upstream oxygen sensor heater

- AC019 Downstream oxygen sensor heating

- AC038 Low speed fan motor relay

- AC039 Engine cooling fan high speed relay

- AC047 OBD warning light

- AC070 A/C compressor

- AC109 Idle speed control

- AC116 Coolant temperature warning light

AC015 - Fuel pump relay

Diagnostic hints

There must be no current or stored faults.

Check for 12 volts at terminal "B3" of the fuel pump relay. If necessary, troubleshoot the circuit up to the fuse.

With the starter engaged, check for 12 V on terminal "B5" of the fuel pump relay.

Replace the fuel pump relay if necessary.

Check for open and short circuits in circuits:

- - fuel pump relay, contact "B5" - contact "C1" of the fuel pump;

- - "ground" - contact "C2" of the fuel pump.

Troubleshoot if necessary.

If the problem persists, replace the fuel pump.

Repeat conformity check after troubleshooting.

AC116 - Warning lamp for emergency coolant temperature

Diagnostic hints

- There must be no current or stored faults.

- Check for ground in the signal light circuit when the control signal is applied.

- Troubleshoot if necessary.

- If the problem persists, run a fault finding on the instrument cluster.

- After the fault has been eliminated, repeat the conformity check.

Troubleshooting Algorithm (FLT)

APN 1- No communication with ECM

No diagnostic hints

Check for 12 V voltage on pin "16" of the diagnostic connector.

If necessary, repair the fault in the circuit up to the fuse.

Check for the presence of "ground" on pins "4" and "5" of the diagnostic connector.

Troubleshoot if necessary.

Using a universal contact board, check for open and short circuits in the circuits:

- - ECU, terminal "28" - "ground";

- - ECU, terminal "33" - "ground";

- - ECU, pin "3" - "ground";

- - ECU, pin "56" - pin "7" of the diagnostic connector;

- - ECU, pin "26" - pin "15" of the diagnostic connector;

- - ECU, terminal "29" - fuse;

- - ECU, terminal "30" - fuse.

Troubleshoot if necessary.

After troubleshooting, perform a system check using the diagnostic tool.

APN 2- Engine does not start or starts with difficulty

Diagnostic hints

- Perform after a full system check using the diagnostic tool.

- Make sure the starter is good.

- Check if there is fuel in the tank (if the fuel level sensor is faulty).

- Check for kinked hoses (especially after removal).

- Check the condition of the fuel filter.

- Check the condition of the fuel tank.

- Make sure the atmosphere tank's message is intact.

- Check the power supply to the fuel pump.

- Check idle speed control.

- Disconnect the hose from the canister purge solenoid valve to the intake manifold. Plug the hose to avoid air leaks.

- If the normal operation of the engine is restored, then the violation is caused by a malfunction of the canister purge valve.

- Check the condition of the spark plugs and ignition coil.

- Ensure that the correct type of spark plugs and ignition coils are installed on the vehicle.

- Check the compression in the engine cylinders.

- Check the valve timing.

- After troubleshooting, perform a system check using the diagnostic tool.

APN 3- Engine idling error

Diagnostic hints

- Perform after a full system check using the diagnostic tool.

- Check if there is fuel in the tank.

- Check for kinked hoses (especially after removal).

- Check the condition of the fuel filter.

- Check the condition of the fuel tank.

- Make sure the atmosphere tank's message is intact.

- Check the connection and condition of the idle speed control connector.

- Troubleshoot if necessary.

- With the ignition on, run command AC109 using a scan tool and test the idle speed control.

- Troubleshoot if necessary.

- Disconnect the hose from the canister purge solenoid valve to the intake manifold. Plug the hose to avoid air leaks.

- If the normal operation of the engine is restored, then the violation is caused by a malfunction of the canister purge valve.

- Check the condition of the spark plugs and ignition coil.

- Ensure that the correct type of spark plugs and ignition coils are installed on the vehicle.

- Check with the dipstick

APN 4 - Deterioration of driving performance of the car (failures during acceleration, interruptions in engine operation, etc.)

Diagnostic hints

- Perform after a full system check using the diagnostic tool.

- Check that the air filter is not dirty or deformed.

- Check if there is fuel in the tank.

- Check for kinked hoses (especially after removal).

- Check the condition of the fuel filter.

- Check the condition of the fuel tank.

- Make sure the atmosphere tank's message is intact.

- Disconnect the hose from the canister purge solenoid valve to the intake manifold. Plug the hose to avoid air leaks.

- If the normal operation of the engine is restored, then the violation is caused by a malfunction of the canister purge valve.

- Check the condition of the spark plugs and ignition coil.

- Ensure that the correct type of spark plugs and ignition coils are installed on the vehicle.

- Check the exhaust system (catalytic converter) for capacity limitation.

- Check with the dipstick that the oil level is correct.

- Make sure the brake booster is sealed.

- Make sure there is no air leak in the intake manifold.

- Check the throttle tube for contamination.

- Check the compression in the engine cylinders.

- Check the valve timing.

After troubleshooting, perform a system check using the diagnostic tool.