An electromagnetic nozzle is an electromechanical valve that works on the principle of an electromagnet

When voltage is applied to the nozzle winding, an electromagnetic field is created that draws the core along with the locking device needle and passes fuel to the spray holes

An additional fuel filter is installed in the injector inlet.

Checking the injector without removing it from the engine

To check the health of the injector, turn off the ignition and remove the "negative" terminal of the battery.

To check the health of the injector, turn off the ignition and remove the "negative" terminal of the battery.

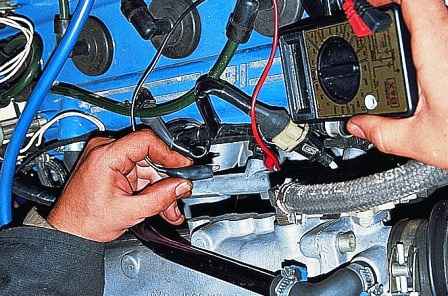

With an awl or a thin screwdriver, snap off the spring clip of the shoe.

Disconnect the connector from the injector.

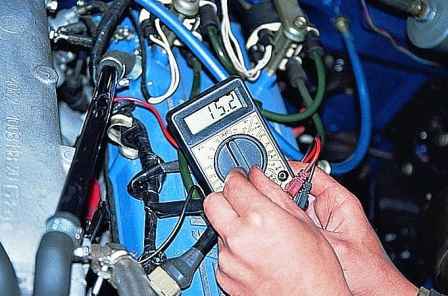

Having connected an ohmmeter to the injector terminals, we measure the resistance of its winding.

The winding of a working injector should have a resistance of 15-16 ohms between the central and side pins of the connector.

Further tests are carried out on the nozzle removed from the engine.

When the voltage is applied briefly from the battery, a distinct click should be heard.

Remove the sealing collar from the nozzle flange and connect the nozzle with a rubber hose with a clamp to a source of compressed air (a compressor with a pressure gauge or a foot pump).

Having lowered the nozzle sprayer into kerosene, we supply air to it at a pressure of 3 kgf / cm2.

For a working nozzle, air should not pass through the atomizer.

We connect the ground wires that were removed from the intake manifold studs during the removal of the injectors.

Having tightened the nuts, with a key of 13 we tighten the contact with the ground.

We put the inlet hose of the fuel rail on the nozzle flange and tighten the clamp with a screwdriver.

We connect two wires with a length of at least 1 meter to the injector terminals.

After making sure that the ignition is off, we connect the "negative" terminal of the battery.

Turn on the ignition and, after waiting for the fuel pump to stop working, turn off the ignition.

Having fixed the nozzle over the container, we connect the wires to the battery terminals for a short time

The nozzle should produce a conical jet of finely atomized fuel.

If the nozzle does not work, reverse the polarity of the wires.

Relieve the pressure in the fuel line by applying voltage to the injector. Drain the gasoline into a suitable container.

We replace the defective nozzle.

Removing and installing the injector

Disconnect the secondary air regulator connector.

Remove the air supply hose and disconnect the throttle cable from the throttle body.

Use a screwdriver to loosen the clamp of the lower (outlet) hose of the idle speed regulator.

Using a screwdriver, loosening the clamp, remove the hose of the crankcase ventilation system.

Loosen the clamp, remove the vacuum brake booster hose.

Using a screwdriver, loosening the clamp, remove the fuel pressure regulator hose

Using the “13” key, unscrew the nut that secures the tip of the “ground” wire to the first intake manifold stud

Similarly, disconnect the wire from the last intake manifold stud.

Then, having unscrewed the remaining nuts of the intake manifold studs with the “13” wrench, remove the receiver.

Loosening the clamp, remove the supply hose from the fuel rail fitting.

Loosen the clamp, remove the crankcase ventilation hose from the idle system pipe.

Loosen the clamp and remove the drain hose from the fuel pressure regulator fitting.

Using the “10” key, unscrew the two bolts securing the fuel rail to the intake manifold and remove the rail

Prying off the spring latch of the block with an awl, disconnect the connector from the nozzle.

Remove the nozzle from the manifold.

Install the nozzle in reverse order.