Belt tension should be checked at every maintenance

The belt must be replaced if the belt is inspected to reveal:

- - signs of wear of the serrated surface, cracks, cuts, folds or delamination of fabric from rubber;

- - traces of oil on the surface of the belt.

If traces of oil are found on the belt, you need to find out the cause (usually this is a violation of the tightness of the seals) and eliminate the cause of the oiling of the belt.

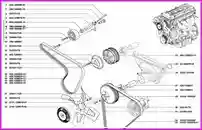

Checking and adjusting the tension of the alternator and water pump drive belts

We need keys for 10 and 13

Loosen the tension roller mounting bolt

We adjust the belt tension with the adjusting bolt

We achieve a deflection of the drive belt of the generator and the water pump, equal to 13-15 mm with a load of 80 N (8 kgf) applied in the middle of the belt branch between the generator and the water pump.

Tension can be controlled by pulling back a branch of the belt with spring balances such as steelyards.

After adjustment, tighten the tension roller mounting bolt.

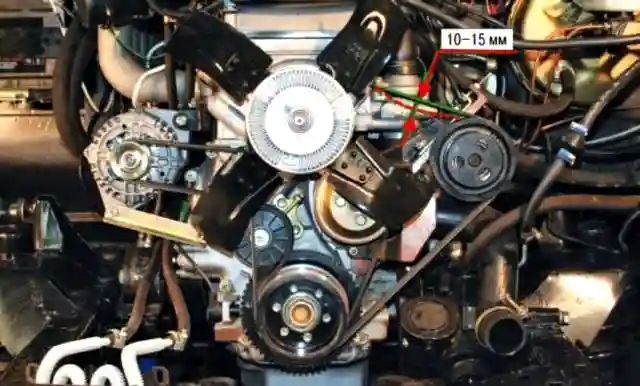

Checking and adjusting the fan drive belt and power steering pump

Proper adjustment of the belt affects its service life.

A normally adjusted belt sags by 10-15 mm when a load of 80 N (8 kgf) is applied in the middle of the belt branch between the fan pulley and the power steering pump

The tension of the fan drive belt and power steering pump is adjusted by moving the power steering pump.

Loosen the two bolts securing the pump to the bracket

By turning the adjusting bolt, we adjust the belt tension by moving the pump along the guides of the bracket.

After that, tighten the mounting bolts

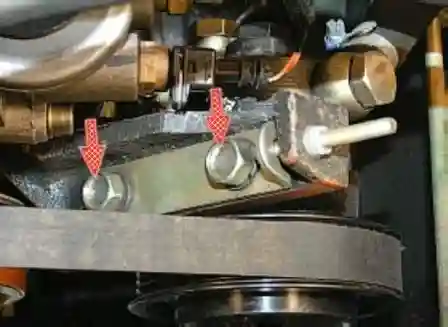

Some vehicles do not have power steering

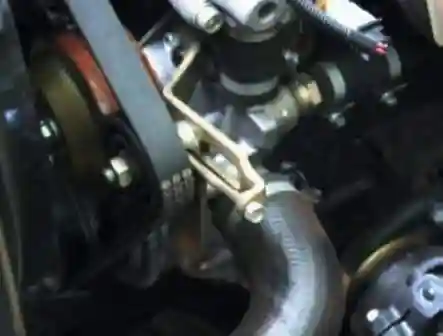

And instead of the power steering pump, a roller is attached to the engine, which ensures the correct coverage of the pulleys and belt tension

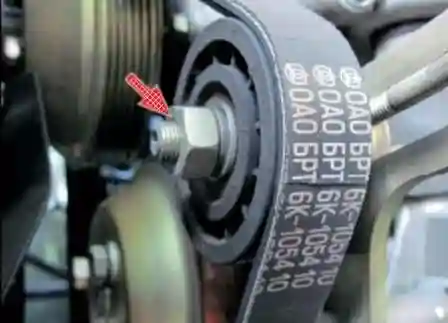

To remove the belt or adjust the tension, loosen the roller axle nut

Turn the tension bolt and adjust the belt tension

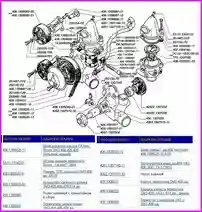

The drive belt of the water pump and the generator of the ZMZ-409 engine (environmental class 3) is tensioned using an automatic tensioner.

It is not necessary to adjust the belt tension during operation.

Only the automatic tensioner is checked with the belt removed.

In case of binding, the belt tensioner is replaced.

Part numbers according to the spare parts catalog