We remove the gearbox for repair or replacement

We prepare the car for the task and install it on a lift or a viewing ditch

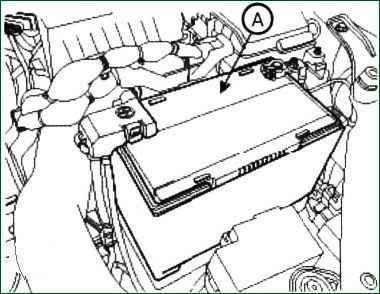

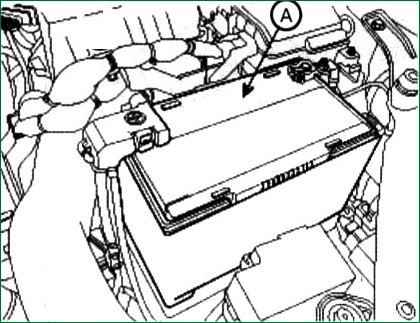

Disconnect the battery terminals and remove the battery

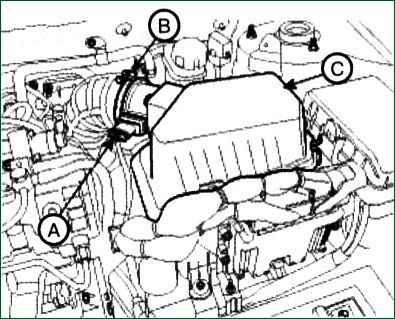

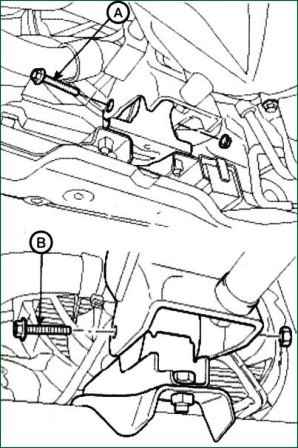

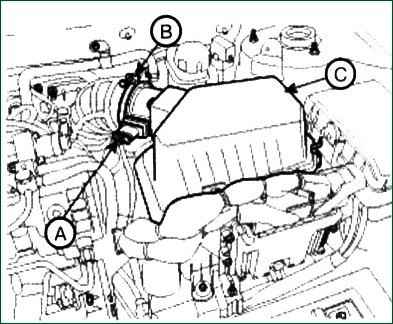

Unscrew the mounting bolts and remove the air duct assembly (A)

We unscrew the mounting bolts and disconnect the control unit (ECM) (A)

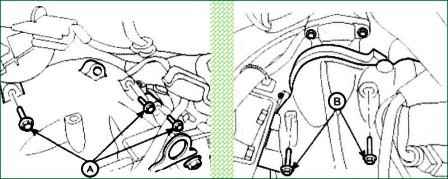

Remove the air filter assembly (C) after disconnecting the ground wire connector (A) and clamp (B)

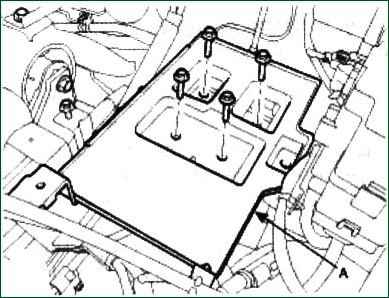

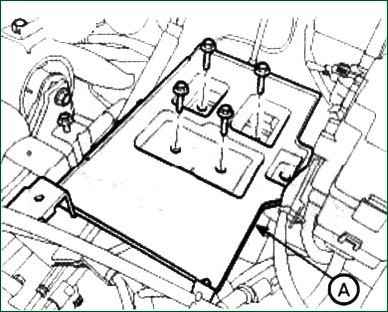

Remove the battery shelf (A)

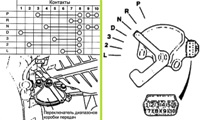

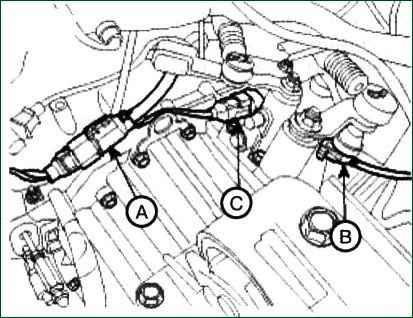

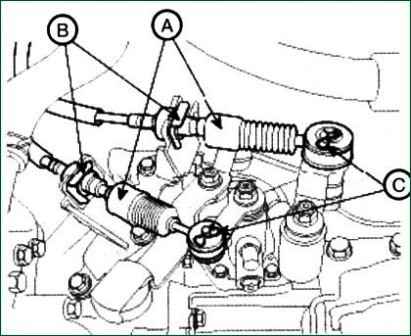

Disconnect the joint connector of the vehicle speed sensor (A), reverse lamp switch (B) and neutral switch (C)

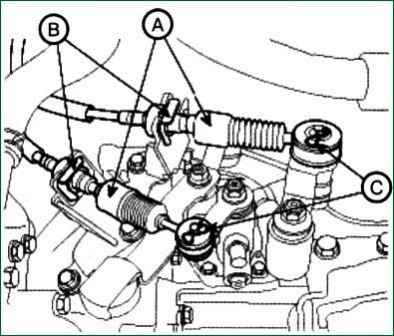

Remove the spring pins (C), remove the clips (B), then disconnect the select and shift cables (A).

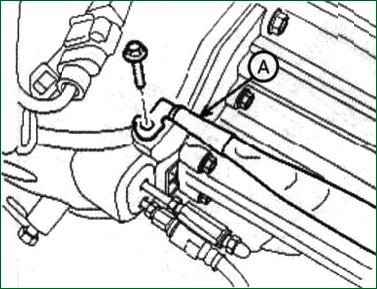

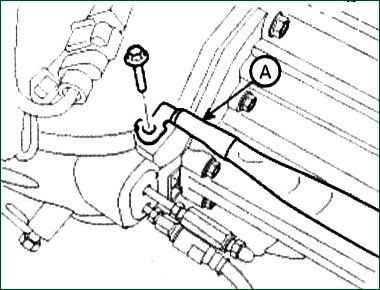

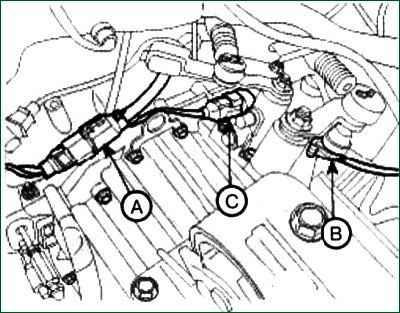

Unscrew the bolt and disconnect the ground wire (A)

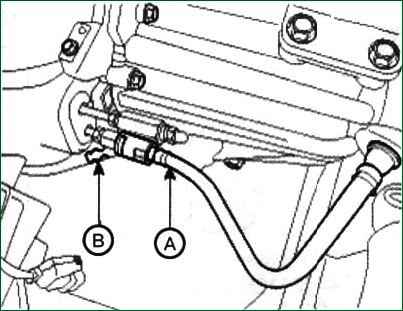

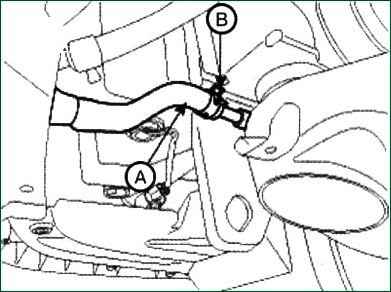

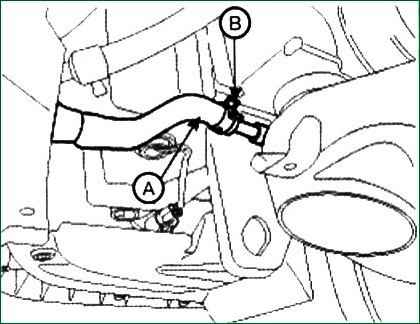

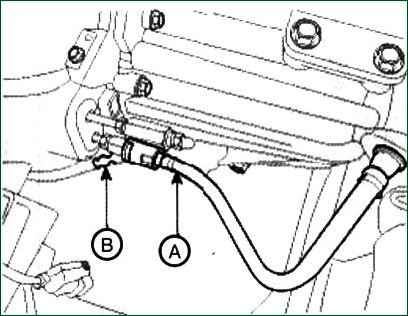

After removing the clamp (B) with the auxiliary cylinder nozzle, disconnect the nozzle (A)

Unscrew the upper gearbox mounting bolts

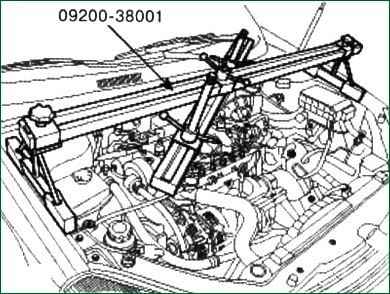

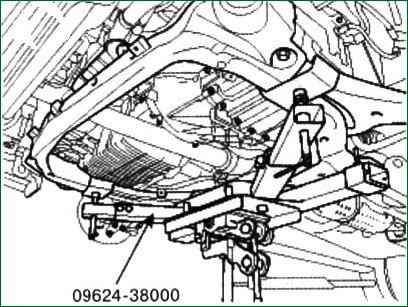

Using tool 09200-38001, we fix the power plant

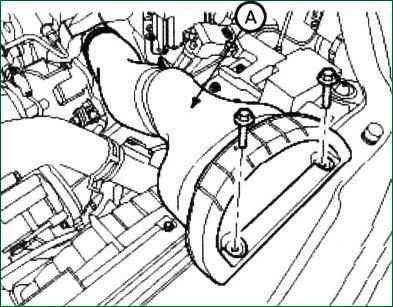

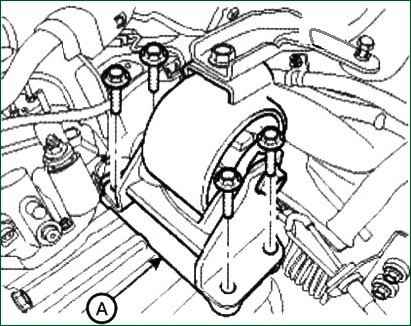

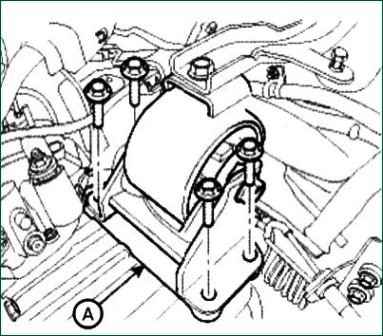

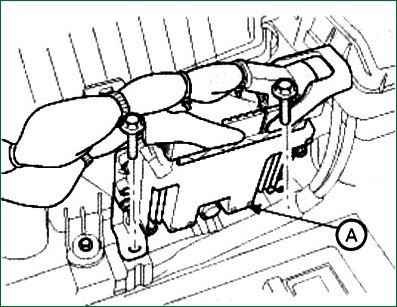

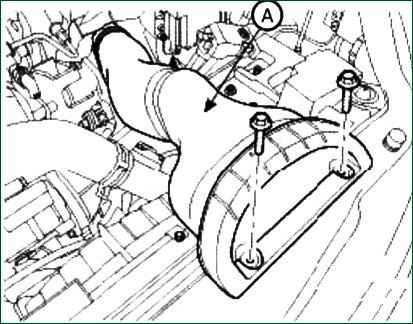

We unscrew the four bolts and remove the gearbox mounting bracket (A)

Remove the front wheels

Unscrew the bolt securing the steering column shaft hinge

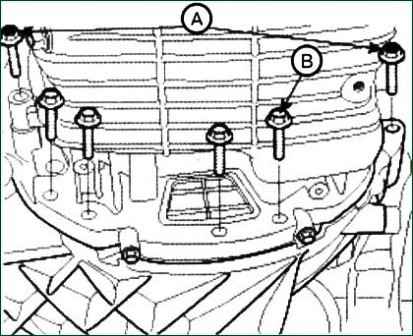

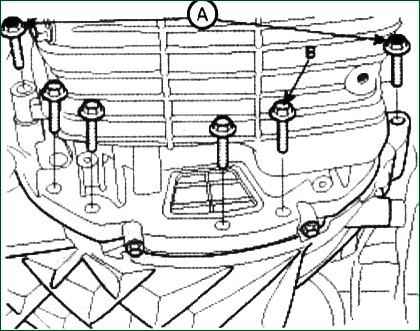

Remove from power plant protection

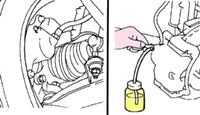

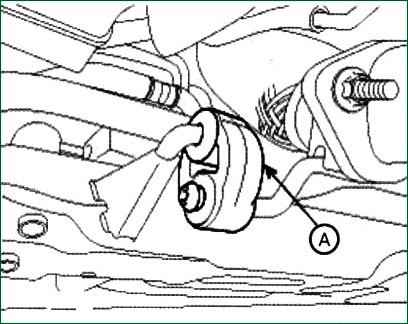

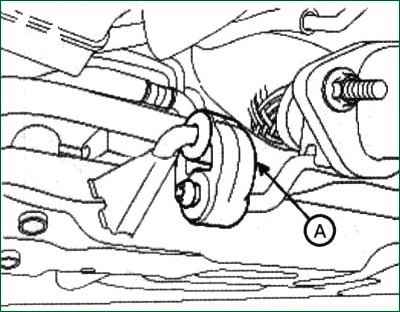

Unscrew the plug (A) and drain the gear oil. Unscrew the filler cap

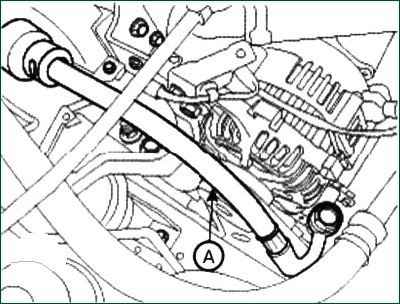

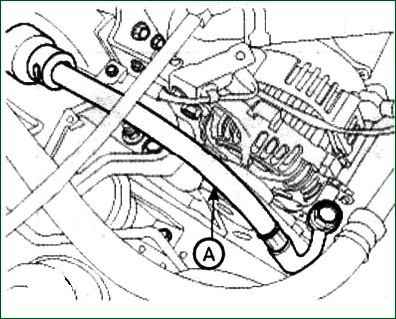

Unscrew the bolt (B) of the pressurized fluid supply hose (A)

We unscrew the bolts of the ball joint of the lower arm

We unscrew the bolts of the anti-roll bar strut

After removing the steering knuckle and nut from the tie rod end, disconnect it

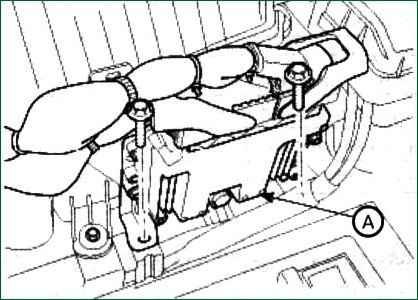

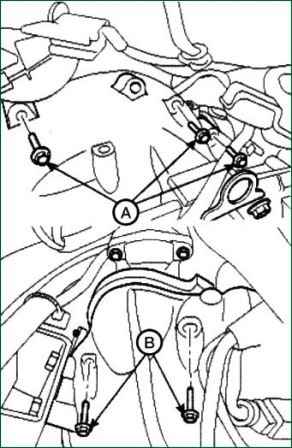

Unscrew the engine mounting bolts (A, B)

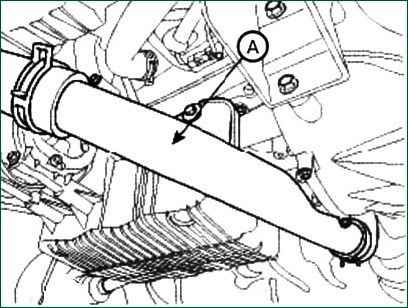

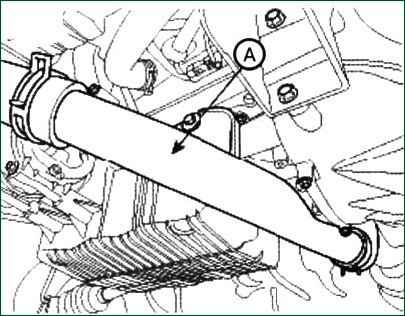

Disconnect the rubber muffler mounting bracket (A)

We support the subframe with a jack and unscrew the fastening bolts

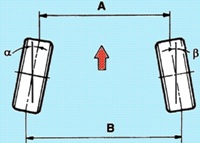

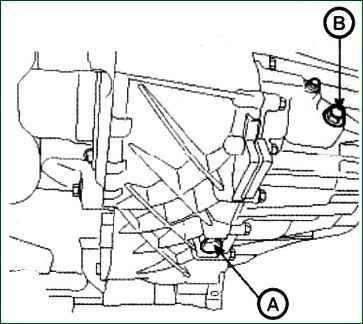

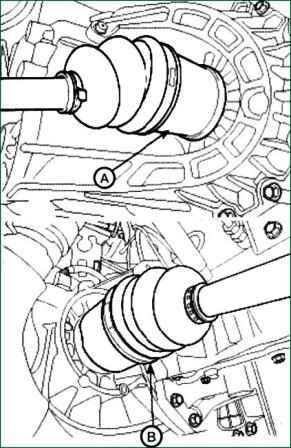

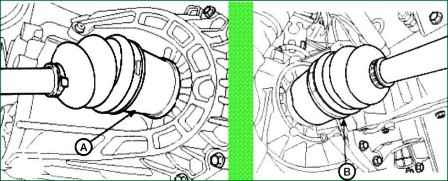

Disconnect the drive shafts (A, B) from the gearbox as shown

We unscrew the two bolts and remove the clamp, then remove the intercooler pipe (A)

Supporting the gearbox with a jack, unscrew the lower bolts of the gearbox

Slowly lowering the jack, disconnect the gearbox from the engine

Installing the gearbox

We connect the gearbox to the engine and bait the lower mounting bolts

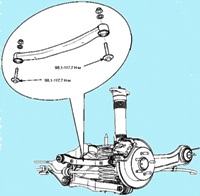

Tighten the bolts with a torque of 80-100 Nm (bolt A), 30-42 Nm (bolt B)

We connect the drive shafts (A, B) to the gearbox

We screw in two bolts and tighten the clamp, then install the intercooler tube (A)

We support the subframe (A) with a jack, then install the support bolts. Tightening torque 140-160 Nm

Connect the rubber muffler mounting bracket (A)

Install the support bracket mounting bolts. Tighten the fastening bolts to a torque of 50-65 Nm

Tighten the clamp (B), then connect the tie rod return hose (A)

Install the rod on the hinge. We tighten the fastening bolts with a torque of 24-34 Nm

We screw in the stabilizer strut mounting bolts. Tightening torque 100-120 Nm

We screw in the bolts of the ball joint of the lower arm

Fill transmission fluid through the filler hole. Plug tightening torque 30-35 Nm

We screw in the tie rod joint bolt. Tightening torque 18-25 Nm

Installing the protection of the power plant

We screw in the bolts (A) of the box mounting bracket. Tightening torque 60-80 Nm

Remove support 09200-38001

We screw in the upper bolts of the box (A, B). Tightening torque 43-55 Nm

Install the power steering high pressure hose (A). Tightening torque 55-65 Nm

We connect the branch pipe of the auxiliary cylinder (A), install the clamp (B)

Connect the ground wire (A)

We connect the cables for selecting and shifting gears (A), install the clamps (B) and locking fingers (C)

Connect the vehicle speed sensor connector (A), tail light switch (B) and neutral position switch (C)

Installing the battery shelf

Install the electronic engine control unit

Install the air filter assembly (C) and connect the ground wire connector (A), then tighten the clamp (B)

Installing the air filter (A)

Install the battery and connect the terminals. First the positive terminal, then the negative terminal.