Microprocessor control system for gasoline internal combustion engine ZMZ-40524.10 is intended for:

- - to ensure optimal engine operation in all modes, taking into account fuel efficiency, emissions of toxic substances in exhaust gases, starting and driving qualities of the car;

- - for automated monitoring of the technical condition of the engine and control system elements responsible for meeting toxicity standards, as well as for external diagnostics in accordance with the requirements of EOBD (European On-board Diagnostics - European on-board diagnostics).

A feature of the ZMZ-40524 engine control system is:

- - the use of a throttle module with an electric motor that allows you to adjust the throttle position electronically to obtain the optimal mixture and the required torque flow characteristics on the car;

- - the use of a drainless fuel line assembly with injectors with a working pressure in the line (400 ± 8 kPa), to reduce the evaporation of gasoline vapors.

- - use of individual ignition coils to reduce the level of interference;

- - implementation of the European on-board diagnostic system EOBB, which monitors the technical condition of the system components responsible for exceeding the limit values of harmful substances in the exhaust gases of a car.

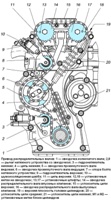

Sensors and components of the control system located on the engine

Synchronization sensor (engine crankshaft position) DG-6K0 261 210 302 Bosch (40904.3847010) or similar, inductive type, located on the chain cover near the crankshaft pulley.

Generates an electrical signal when the magnetic field of the sensor interacts with a special toothed disk (60-2 teeth) mounted on the crankshaft pulley.

The mutual orientation of the synchronization disk and the sensor is such that the moment when the sensor axis passes the runoff of the twentieth tooth of the synchronization disk corresponds to the presence of the piston of the first and fourth cylinders at top dead center

The tooth number is counted from the gap in the direction opposite to the rotation of the engine crankshaft.

The sensor is designed to determine the angular position and speed of the engine crankshaft by the control unit.

Phase sensor (camshaft position) PG-3,8 0232103048 Bosch (40904.3847000) or similar, on the Hall effect, located on the cylinder head.

Generates a signal when the magnetic field of the sensor interacts with a marker (bent plate) mounted on the exhaust camshaft.

The moment of the beginning of signal generation by the phase sensor, in the presence of coincidence of the run-off of the first tooth of the disk 60-2 with the axis of the synchronization sensor, indicates the beginning of the compression stroke in the first cylinder

Tooth number reading - from the gap in the direction opposite to the rotation of the engine crankshaft (see crankshaft position sensor).

The phase sensor is designed to determine the phase of the working cycle in the engine cylinders by the control unit.

Throttle module with electric drive and throttle position sensor ETB TS A2C5 330 30 f. Siemens (40624.1148090).

The drive is a DC motor with the voltage of the on-board network, the position sensor damper control - magnetoresistive (two-channel).

The throttle module is located on the intake pipe.

The throttle module is designed to control the filling of engine cylinders with air during start-up, warm-up, idle, when turning on / off external power consumers, at various loads - in order to optimize torque.

The sensor is designed to determine the angular position of the throttle by the control unit.

Coolant temperature sensor (engine temperature condition) TF-W0 280 130 093 Bosch or similar, (40904.3828000).

The sensor is located on the thermostat housing.

The sensor is designed to measure the engine coolant temperature by the control unit.

Knock sensor KS-4-S0 261 231 176 Bosch (40904.3855000) or similar, piezoelectric, located on the cylinder block on the intake side, in the area of the 4th cylinder.

The sensor is designed to detect knocking combustion in the engine by the control unit.

Ignition coils ZS-K-1x1 0 221 504 027 Bosch (40904.3705000*) or similar, individual, four, transformer type, mounted on the valve cover.

Designed to generate high voltage energy for spark plugs.

Spark plugs DR17YC Bosch or similar, small size, with noise suppression resistor, four, screwed into the cylinder head in the center of the combustion chambers

Fuel rail (fuel distribution line) with solenoid injectors ZMZ6354 (DEKA1D) Siemens assembly (40624.1100010*).

Intake pipe placement. Drainless ramp, steel, with fitting for quick coupling.

The fuel rail is designed to supply fuel to the engine cylinders.

Sensors and control units located on the vehicle

Mass air flow sensor DMRV 20.3855-10 (HFM62C / 19 Siemens), hot-film, film, located between the air filter and the engine throttle.

DMRV is designed to determine the air flow (cylinder filling) of the engine by the control unit.

The DMRV has a built-in temperature sensor, thermistor type.

The sensor is designed to measure the intake air temperature by the control unit.

Oxygen concentration sensors

Oxygen sensors (lambda probes) OSP+ 25368889 f. Delphi, two, zirconium, with controlled electrical heating.

- - (1) the main lambda probe, located before the converter, on the exhaust pipe of the car exhaust system.

Designed to determine the composition of the mixture before the converter (at the engine outlet) by the control unit.

- - (2) additional lambda probe, located in the converter housing, at its outlet.

Designed to determine the composition of the mixture after the converter by the control unit.

Oxygen sensor heating circuits are controlled directly from the control unit.

Accelerator pedal module 6PV010 033-00 f. Hella, accommodation in the car.

Designed to set the engine load by the driver.

The pedal position sensor, potentiometric, two-channel, is built into the pedal mechanism.

Designed to determine the accelerator pedal position by the control unit.

Rough road sensor 2123.1413130-0Z or 28.3855000, piezoelectric, located on the car body, in the area of the shock-absorbing cups of the front suspension.

The sensor measures the acceleration that occurs when the vehicle is moving on a rough road.

The sensor is designed to detect vibrations of the car body transmitted to the transmission by the control unit.

Vehicle speed sensor 343.3843 or ADS-6 NK, on the Hall effect, placed on the gearbox speedometer drive.

Designed to measure the vehicle speed by the control unit.

Gasoline vapor adsorber 21103-1164010 with purge valve 21103-1164200, electromagnetic, placed in the engine compartment of the car.

Designed to capture fuel vapors from the gas tank and accumulate them in the adsorber.

On command from the control unit, the valve switches the line connecting the adsorber and the engine intake pipe (supply - through the fitting, behind the throttle module).

The valve is designed to purge (regenerate) the adsorber.

Submersible fuel pump module with electric drive, fuel pressure regulator (400±8 kPa), coarse filter and fuel level sensor, placed in the car's gas tank

The module is designed to maintain constant fuel pressure in the line.

Fuel fine filter, 315195-1117010 (FTO15-1117010) or 315195-1117010-01 (NF-014-T), located in the fuel line, between the fuel pump module and the fuel rail.

The filter is designed to filter out particles in the fuel.

Clutch engagement sensor 15.3720, switch, switches the on-board network voltage +12 V, as a sign of clutch engagement, to the control unit, placed on the clutch pedal.

Designed for identification by the control unit of the moment of switching on/off the gear to determine the engine operating mode (idling, transmission engaged) and throttle control parameters.

Brake sensor 21.3720, two-channel switch, placed on the brake pedal.

Switches two signals simultaneously when pressing the brake pedal:

- - breaks the voltage circuit of the +12 V on-board network to the control unit (sign of pressing the brake pedal),

- - switches the +12 V on-board network voltage supply to the “stop lamp” and to the control unit (sign of turning on the “stop lamp”).

The sensor is designed for both safety monitoring function of the throttle control by the control unit.

Diagnostic connector — 16-pin OBD-II J1962 connector, placed in the car on the accelerator pedal bracket.

The connector is designed to provide information exchange of the control unit with diagnostic equipment via a single-wire K-line communication line in accordance with ISO9141-2.

The memory of the control unit stores the vehicle operation parameters and information on malfunctions in the form of fault codes, available for reading by diagnostic equipment through the diagnostic connector.

Electromagnetic relay, placement in the engine compartment of a car, 90.3747000 -10 or another type.

Designed to switch the voltage of the car's on-board network on command from the control unit:

- - (Main) - for actuators, control system sensors and control unit

- - (Gasoline pump) - to the electric drive of the submersible gasoline pump;

- - (Fan clutches) - on the electromagnetic clutch of the cooling system fan drive.

Diagnostic indicator is a yellow (orange) lamp with a motor symbol, placed on the dashboard of a car.

The indicator is designed to indicate malfunctions in the functioning of the control system and perform the functions of on-board diagnostics EOBD.

The fault indicator operates in three modes:

- - disabled (no faults);

- - continuous glow (fault present) - serious violations affecting emissions of toxic substances and control functions that need to be eliminated;

- - flashing indication (0.5 sec - on, 0.5 sec - off) - when an unacceptable level of misfiring is detected, followed by turning off the fuel supply to the engine cylinder (continuous glow), indicating an immediate stop of the car to prevent damage to the converter and traffic safety violations.

When the ignition is turned on, the indicator should turn on, and if the on-board diagnostics does not detect any malfunctions, it should turn off after 3...5 seconds.

The absence of a lamp indication before starting the engine indicates violations in the indicator control circuit, which is unacceptable during operation.

If the indicator stays on after the ignition switch is turned on, this indicates a malfunction.

Starting the engine and driving the car when the malfunction lamp is on, in order to prevent damage to the converter or disruption of control functions, without prior system diagnostics is undesirable

Control unit371.3763 Mikas 11ET, microprocessor, located in the engine compartment of the car.

The design of the control unit may vary depending on the vehicle equipment.

Wiring harness for control system, 3302-3761581 or other name, depending on the vehicle equipment.

The control system prevents emergency operation:

- - exceeding the maximum crankshaft speed (with the exception of forced engine cranking) - by turning off the fuel supply to the cylinders,

- - detonation combustion,

- - maintains the temperature of the coolant within the operating range by controlling the operation of the electromagnetic fan clutch,

- - detects misfires and calculates the temperature of the exhaust gases at the engine outlet, with subsequent shutdown of the fuel supply in the faulty cylinder when the misfire limit is reached,

- - calculates the temperature of the converter, and in case of exceeding the threshold temperature value, enriches the air-fuel mixture (during normal operation of the engine cylinders),

- - registers and stores in memory information about emergency operation conditions.

The control system provides the ability to move the car with faulty sensors, without guaranteeing the preservation of the passport characteristics of the engine and the car:

- - if the mass air flow sensor fails,

- - if the intake air temperature sensor fails,

- - in case of failure of the coolant temperature sensor,

- - on failure one of the throttle position sensors,

- - in case of minor malfunctions of the throttle actuator,

- - if one of the electric accelerator pedal position sensors fails,

- - in case of failure of one oxygen sensor (or its heater circuit) - to the neutralizer,

- - in case of failure of the oxygen sensor (or its heater circuit) - after the converter,

- - if the knock sensor fails,

- - in case of failure of the camshaft position sensor (transition to pair-parallel fuel injection and ignition),

- - in case of malfunction of the fuel vapor recovery system and the canister purge valve,

- - if the vehicle speed sensor fails,

- - if one of the brake limit switches fails,

- - if the brake pedal switch fails,

- - if the clutch limit switch fails,

- - in case of failure of the air conditioning compressor clutch relay,

- - when the rough road sensor fails.

During the operation of the control system, maintenance of its individual components, including the control unit, is not provided.

Restoring the normal functioning of the control system is carried out by replacing its elements.

To diagnose the ZMZ-40524 engine control system, the ASKAN-10 diagnostic tester with the PM Mikas 11 Euro 3 (DM11 E3) software module and the OBDII connection cable is used.