Bleeding the power system

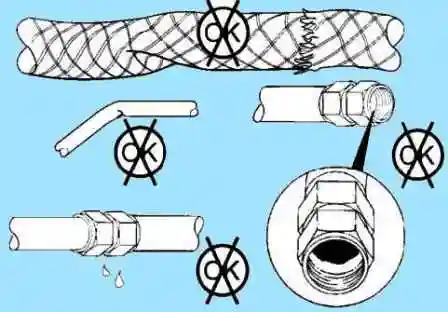

It is necessary to bleed the engine power system after replacing fuel filters and during other work related to the removal of parts of the power system, as well as when air enters the system

To complete the task, you will need a key for 12 and rags.

We put a piece of cloth (rags) around the fine filter.

Unscrew the air bleed plug.

We press the button of the manual priming pump several times until the fuel starts to come out of the hole.

Removing water from the fuel filter

In the instrument cluster there is a warning light for the presence of water in the fuel.

If this lamp does not go out after starting the engine, then there is water in the fuel.

In this case, stop the engine and drain the water from the fuel filter.

We install a container for draining fuel under the drain cock.

Open the drain cock by turning the wing nut counterclockwise 2 turns

To facilitate draining, unscrew the plug on the filter housing lid

Drain the fuel from the filter along with the sludge.

After that, press the booster pump button several times until the fuel flows out of the filter completely.

Close the faucet by turning it clockwise.

After that, we pump the power system, as described above.

We screw the bleed plug back in place.

Checking for air in the fuel system

When replacing the fuel supply lines, fuel filters, high pressure fuel pump, high pressure fuel lines and injectors, air enters the fuel system.

This results in starting problems, engine roughness, misfiring in the cylinders, reduced power and uneven fuel delivery.

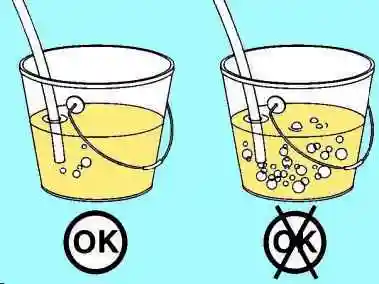

A few air bubbles found in the fuel line during the test are considered normal.

The appearance of many small bubbles (foam) indicates air leakage into the system, high resistance at the inlet, which causes cavitation, or that the system is not filled with fuel properly.

If the resistance at the fuel inlet does not exceed the norm, the source of air ingress should be identified among the following nodes:

- - intake fuel lines;

- - OEM fuel lines;

- - input side of fuel filters;

- - intake pipes in fuel tanks.

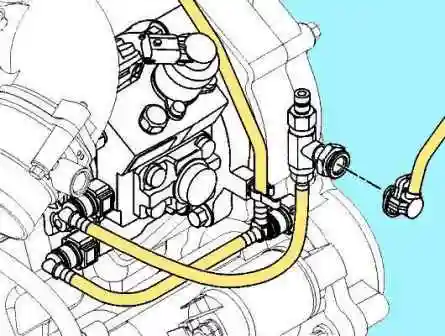

Disconnect the fuel supply line of the booster pump.

Instal a pressure gauge adapter (catalog no. 4918462) or equivalent between the OEM fuel supply line and the fuel pump at the pump inlet.

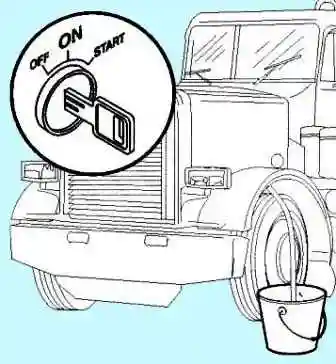

We start the engine and, several times switching from low to high speeds, remove the air that got into the system when connecting the test hose.

We let the engine idle, watching the flow of fuel flowing out of the transparent hose.

If air continues to bubble in the hose for several minutes, then the fuel system is air gets in.

Check the fuel system for damaged fuel lines and loose connections.

Replace damaged fuel lines and tighten loose connections

Checking the resistance of the fuel drain line

The fuel drain line resistance is measured at the drain manifold located near the drain line connection.

You can find it by going through the fuel drain lines from where they supply fuel (common high pressure fuel line relief valve, injector drain fittings, or high pressure pump drain port) to where they connect to another unit.

This node will be the drain manifold.

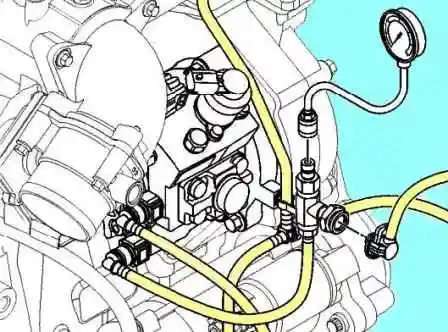

Disconnect the fuel drain line installed between the fuel pump and the manifold.

We install an adapter, catalog No. 4918462, or its equivalent, between the drain manifold and the drain fuel line.

Install the pressure gauge on the adapter fitting.

Turn on the starter, or switch the engine to low idle and measure the pressure.

We observe the readings of the manometer. The maximum resistance of the drain pipe is 50 kPa (7.3 psi).

In case of high resistance of the fuel drain line, check the following components:

- - compliance with the norm of the size of the fuel lines of the complete equipment going to the tank, as well as the absence of leaks, kinks and blockages in them;

- - absence of clogging in the ventilation ducts of the fuel tank