Remove the right lower engine cover

Remove the drain plug with gasket and drain the transmission fluid

Install a new gasket and drain plug.

Tightening torque: 49 Nm.

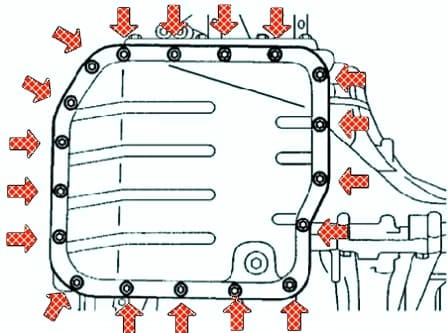

Remove 18 bolts and carefully remove the oil pan (fig. 1).

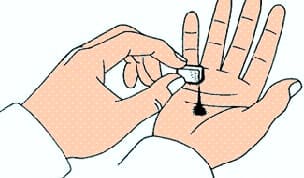

Examine the wear particles in the sump.

Remove 2 magnets and use them to collect steel chips.

Carefully inspect the chips and particles in the sump and on the magnet to assess the wear on the gearbox.

If the suspension is dominated by steel chips and particles that react to the magnet, the bearings, gears and plates are worn out.

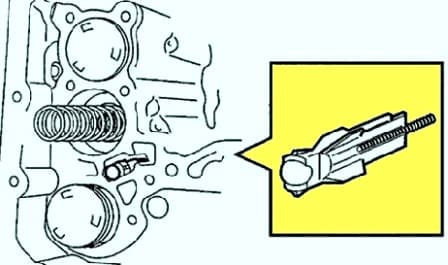

If the suspension is dominated by brass chips and particles that do not react to the magnet, the bearings are worn out (Fig. 2).

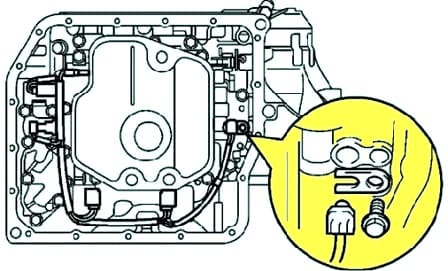

Disconnect the 5 shift solenoid valve connectors.

Remove the bolt and retainer plate and disconnect the transmission fluid temperature sensor (fig. 3)

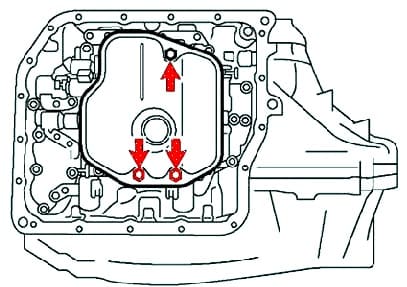

Remove the 3 mounting bolts and remove the oil filter (Fig. 4).

When removing the oil filter, be prepared for some liquid to leak out of it

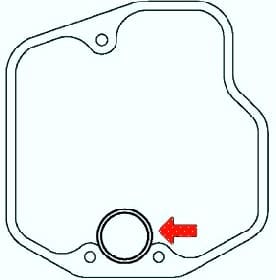

Remove the oil filter O-ring (fig. 5).

Removing the automatic transmission valve block

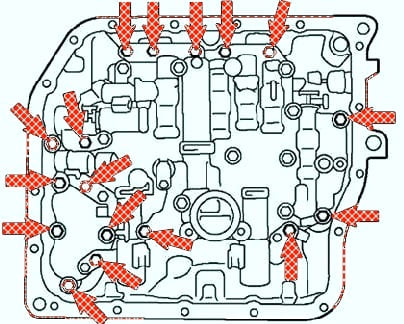

Supporting the valve block, unscrew the 17 mounting bolts and remove the valve block (fig. 6).

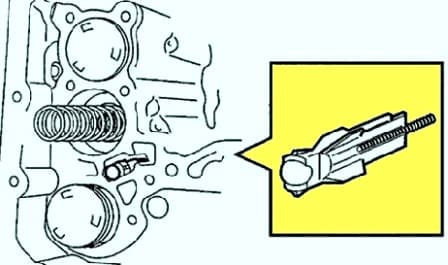

Make sure that the check valve body, spring and accumulator piston do not fall out.

Remove the check valve body and spring (fig. 7).

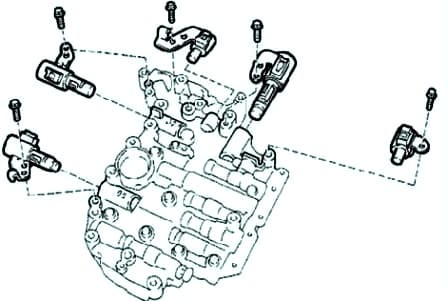

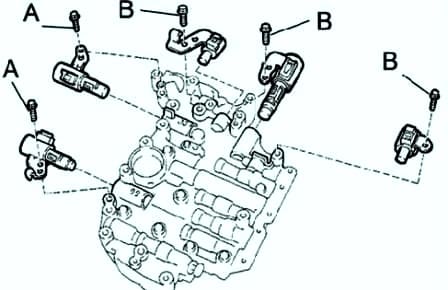

Remove the 5 mounting bolts and remove the 5 shift solenoid valves (fig. 8)

Installing the valve block

Install the 5 shift solenoid valves and secure with 5 bolts (fig. 9).

- Tightening torque: bolt A: 6.6 Nm; bolt B: 10.8 Nm.

- Bolt length: Bolt A: 12mm; bolt B: 45 mm.

Install the spring and check valve body.

Align the groove of the manual valve with the pin on the lever (see fig. 10).

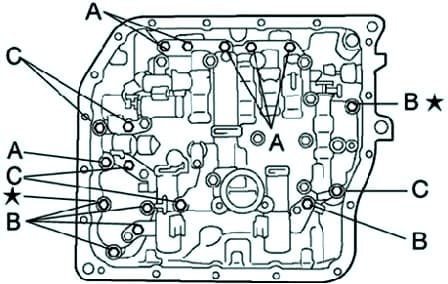

Install the 17 mounting bolts. Tightening torque: 10.8 Nm.

To install the valve, push the valve block against the accumulator piston spring and check valve body.

First, temporarily tighten the bolts marked with an asterisk in figure 11, as they are installation bolts.

Bolt length: Bolt A: 25mm; bolt B: 41 mm; bolt C: 45 mm.

Lubricate the new oil filter O-ring with automatic transmission fluid.

Install the oil filter O-ring.

Install the oil filter and secure with 3 bolts. Tightening torque: 10.8 Nm.

Lubricate the new transmission fluid temperature sensor O-ring with automatic transmission fluid.

Install the sensor, bolt and lock plate. Tightening torque: 6.6 Nm.

Connect the 5 shift solenoid connectors.

Install 2 magnets in the oil pan.

Lubricate the pan mounting bolts with sealant. Sealant: THREE BOND 2430 or equivalent.

Install the oil pan, gasket and tighten the 18 bolts. Tightening torque: 7.8 Nm.

Because the bolts must be tight, apply sealant to them and tighten 15 minutes after applying the sealant.

Fill and check automatic transmission fluid.