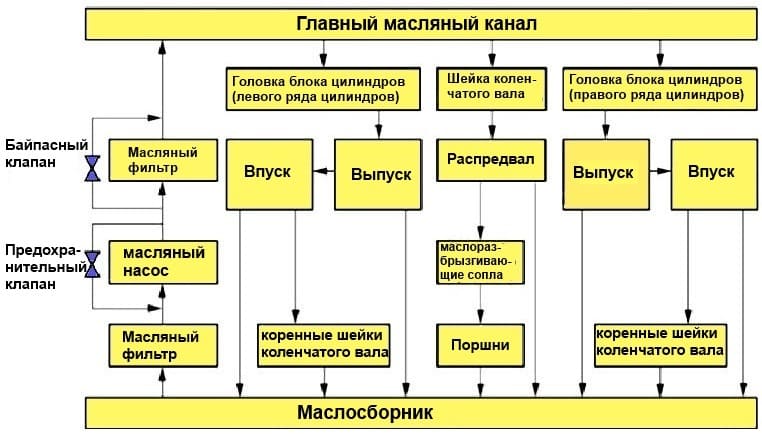

The lubrication system works under pressure, the oil passes through the oil filter

The engine uses a lubrication system with full-flow oil cleaning and pressurized oil supply to the main moving parts and assemblies of the engine.

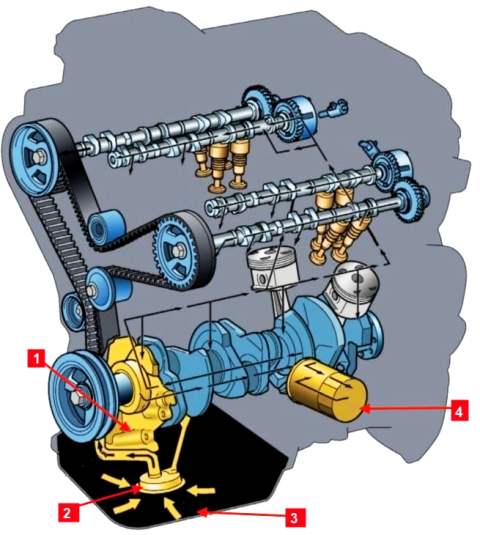

The system consists of an oil sump, a gear oil pump with an oil receiver, a full-flow oil filter, an oil pressure sensor and oil valves.

The oil pump draws oil from the engine sump and delivers it to the oil filter.

There is a bypass valve on the pressure side of the oil pump.

If the oil pressure is too high, the valve opens and some of the oil flows back into the engine sump.

Through the middle of the oil filter element, clean oil enters the main oil line.

When the filter becomes clogged, a bypass valve located in the oil filter housing supplies unfiltered oil directly to the main oil line.

There is a non-return valve in the oil filter pipe, which prevents the oil channels and hydraulic valve lifters from emptying the engine.

Channels for lubrication of crankshaft bearings depart from the main oil line.

Through the inclined holes in the crankshaft, oil is supplied to the connecting rod bearings, and from there it is sprayed onto the piston pins and cylinders.

At the same time, oil is supplied through ascending channels to the cylinder head and ensures lubrication of the camshaft bearings and the operation of hydraulic tappets.

On vehicles equipped with engines with a catalytic converter, make sure that the oil level on the dipstick does not exceed the maximum mark.

If too much oil has been poured into a car with a catalytic converter, the excess must be removed from the crankcase by draining or suction (with a special vacuum pump), otherwise unburned oil will enter the exhaust system and may destroy the catalytic converter.

Filling volume of the 1MZ-FE engine lubrication system:

- - filling dry system - 5.5 l;

- - with oil filter - 4 l;

- - without oil filter - 4 l.

Oil pump

Oil pump with trochoidal gears is driven by a chain from the crankshaft.

Through the pump, the oil receiver takes oil from the engine sump and supplies it under pressure to various friction units.

The oil receiver with a strainer is located in front of the oil pump inlet.

Oil pressure regulator (reducing valve)

The oil pressure regulator (reducing valve) has the function of preventing excess oil supply.

At low speeds, the regulator valve closes the bypass channel under the action of a spring.

While at high speeds, the oil pressure increases, the oil pressure force overcomes the spring force and the governor valve opens.

Excess oil returns to the sump through the valve.

Oil filter

Camry vehicles use a full-flow type oil filter with a replaceable paper filter element.

The filter is installed on the outside of the engine, which allows for relatively quick replacement of the filter element.

A bypass valve is installed in front of the filter element, which opens with an increase in pressure in front of the filter that occurs when the filter element is clogged with contaminants.

The bypass valve opens when the oil pressure exceeds the force of the valve spring.

In this case, the oil passes through the bypass channel, bypassing the oil filter, and goes directly to the main engine oil line.