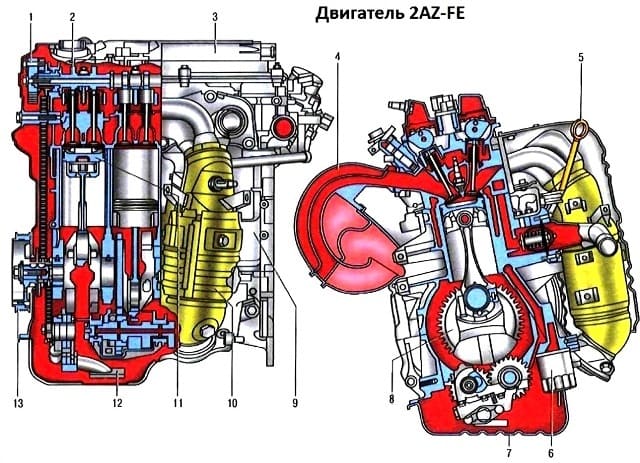

The engine is equipped with an ignition system with individual ignition coils, an intelligent electronic variable valve timing system and an electronic throttle control system

These systems improve the power and dynamic characteristics of the engine, as well as its fuel efficiency and reduce the toxicity of exhaust gases

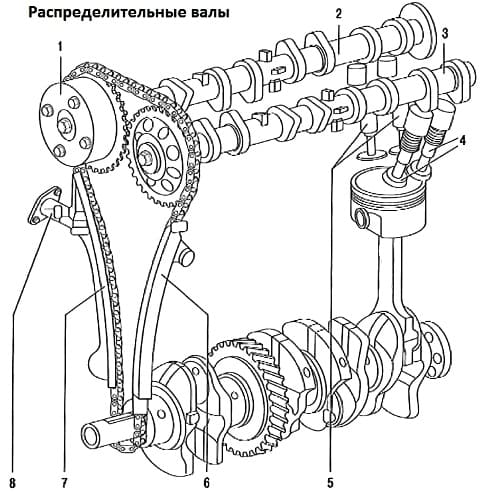

An overhead five-camshaft engine has four valves per cylinder

The camshafts are driven by a roller chain in 8 mm increments

The timing chain is lubricated by an oil spray nozzle

Tensioning the chain with a hydraulic tensioner

The valves are driven directly from the camshafts through cylindrical tappets, which simultaneously serve as adjusting elements of the gaps in the drive

The cylinder head is made of magnesium alloy according to the transverse cylinder scavenging pattern (inlet and outlet channels are located on opposite sides of the head)

Saddles and valve guides are pressed into the cylinder head

The intake and exhaust valves have one spring each, fixed through the plate with two crackers

The cylinder head is centered with two bushings and attached with ten bolts

A non-shrink metal-reinforced gasket is installed between the block and the head

In the upper part of the cylinder head, there are five bearing supports for two camshafts

The lower parts of the supports are made integral with the cylinder head, and the upper parts (covers) are attached to the head with screws

The support holes are machined complete with covers, so the covers are not interchangeable, and each cover has a serial number

To ensure high knock resistance and fuel efficiency of the engine, the combustion chamber is wedge-shaped

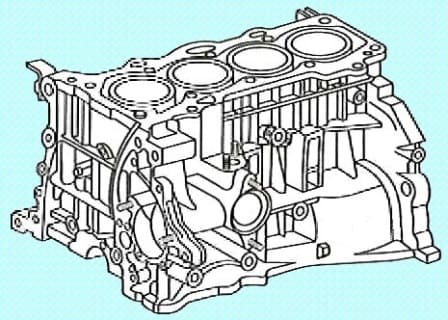

The cylinder block is a single casting of a special lightweight aluminum alloy that forms the cylinders, the cooling jacket, the upper part of the crankcase and the five crankshaft bearings

Thin-walled cast-iron liners are installed in the cylinder block

In the lower part of the block there are five beds of main bearings with removable covers bolted to the block

Main bearing caps machined complete with block and non-interchangeable

The cylinder block has special lugs, flanges and holes for fastening parts, components and assemblies, as well as channels of the main oil line

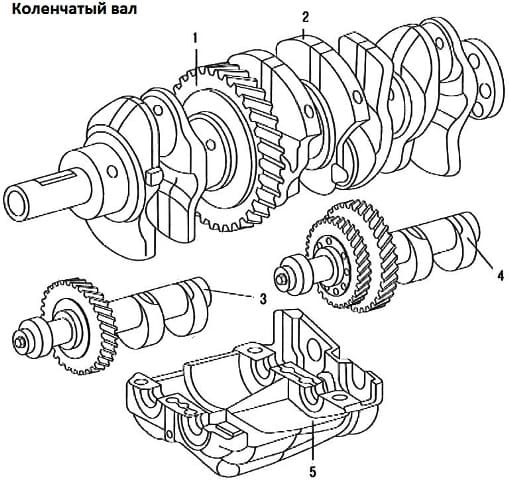

The crankshaft is all-wheel drive, rotates in main bearings with thin-walled steel liners with an anti-friction layer

Eight counterweights are used to optimize the distribution of the load on the crankshaft bearings

A helical gear is installed on the crankshaft to drive the balancing mechanism, the gear is made of plastic

At the front end of the crankshaft is a timing sprocket and an accessory drive belt pulley

Pistons are made of aluminum alloy with a short skirt

On the cylindrical surface of the piston head, there are annular grooves for two compression rings and an oil scraper ring has drillings to drain oil removed from the cylinder walls

Tubular cross-section piston pins are installed in the piston bosses with a gap and are pressed with an interference fit into the upper heads of the connecting rods, which are connected by their lower heads to the connecting rod journals of the crankshaft through thin-walled liners having the same design as the main bearings

Forged steel connecting rods with I-section shank

The connecting rods are processed assembled with donuts

The side surfaces of the connecting rods and caps are marked with the serial number of the cylinder

Casted iron camshafts

The intake camshaft has a timing rotor that powers the camshaft position sensor

An oil channel is provided in the intake camshaft, through which oil is supplied under pressure to the system regulator, which provides a change in valve timing

The gas distribution mechanism is closed by an aluminum cylinder head cover. It has an oil separator of the crankcase ventilation system

Combined lubrication system

A stamped steel oil sump is attached to the bottom of the cylinder block

The oil sump flange is sealed with a sealant-gasket

The crankcase has an oil drain hole

Full-flow oil filter, non-separable, with bypass and anti-drain valve

The crankcase ventilation system is closed, forced, with the removal of crankcase gases through the oil separator into the air filter cavity

The engine cooling system is sealed, with an expansion tank

The engine power system consists of an electric fuel pump installed in the fuel tank, a throttle assembly, a fine fuel filter and a fuel pressure regulator installed in the fuel pump module, a fuel pulsation compensator, injectors and fuel lines and an air filter

Microprocessor ignition system, consists of ignition coils and spark plugs

The ignition coil is controlled by the electronic engine control unit

The power unit (engine with gearbox) is mounted on four supports with elastic rubber elements - two side ones, which take the bulk of the power unit, as well as front and rear, compensating for the torque from the transmission and the loads that occur when the car starts off, acceleration and deceleration

Possible engine malfunctions and solutions

Engine won't start

- no pressure in the fuel rail:

Clogged fuel lines

Rinse and blow out the fuel tank and fuel lines

- fuel pump is faulty

Replace pump

- clogged fuel filter

Change filter

- faulty fuel pressure regulator

Check the regulator, replace the defective one

- Faulty ignition system

Engine runs erratically or stalls at idle

- insufficient pressure in the fuel rail

See above (engine won't start)

- faulty idle speed controller

Replace idle speed control

- air leakage through the crankcase ventilation hoses, a hose connecting the intake pipe to the vacuum brake booster

Tighten the clamps, replace damaged hoses

- clearances in the valve drive mechanism are broken

Check the hydraulic gap compensators, replace the faulty ones

- the ignition system is broken

The engine does not develop full power and does not have sufficient throttle response

- not full throttle opening

adjust throttle actuator

- faulty throttle position sensor

Replace sensor

- insufficient pressure in the fuel rail

We look at the malfunction "Engine does not start"

- air filter dirty

Replace filter element

- - the ignition system is broken

- - clearances in the valve drive mechanism are violated

Check the hydraulic gap compensators, replace the defective hydraulic compensators

- insufficient compression - below 1 MPa (10 kgf/cm2):

Cylinder head gasket broken

Replace gasket

Burn-out pistons, breakage or sticking of piston rings

Clean the rings and grooves of the pistons from carbon deposits, replace the damaged rings and the piston

- poor fit of valves to the seats

Replace damaged valves, grind seats

- excessive wear of cylinders and piston rings

Replace pistons

Insufficient oil pressure in a warm engine

- using the wrong brand of oil

Change the recommended oil

- dilution or foaming of the oil due to the penetration of fuel into the oil sump or coolant

Remove causes of fuel or coolant intrusion. Change oil

- pollution of the working cavity or wear of the oil pump

Flush or repair the oil pump

- clogged oil filter

Change the oil filter

- loosening or clogging of the oil receiver

Fix the oil receiver, wash its filter

- increased clearance between the main or connecting rod bearing shells and the crankshaft journals

Sand the necks and replace the liners

- cracks, pores in the walls of the oil channels of the cylinder block or clogging of the oil lines

Repair the cylinder block. If it is impossible to eliminate the defect, replace the block

- loose installation of oil channel plugs or their absence

Restore the tightness of the plugs, install the missing plugs

Knock of crankshaft main bearings

- insufficient oil pressure

We look at the malfunction "insufficient oil pressure in a warm engine"

- loosened flywheel mounting bolts

Tighten the bolts to the recommended torque

- increased clearance between journals and main bearing shells

Sand the necks and replace the liners

- increased clearance between the thrust flanges of the middle main bearing shells and the crankshaft

Replace middle main bearing shells, check clearance

Rattle of connecting rod bearings

- insufficient oil pressure

See fault "insufficient oil pressure"

- excessive clearance between the connecting rod journals of the crankshaft and the liners

Replace the liners and sand the necks

The sound of pistons

- increased clearance between pistons and cylinders

Replace pistons, bore and hone cylinders

- a large gap between the piston rings and the grooves on the piston

Replace rings or pistons with rings

- the piston is incorrectly installed (the displacement of the hole for the piston pin is directed towards the left side of the engine)

Install the piston correctly

Increased noise of the gas distribution mechanism

- insufficient oil pressure

We look at the malfunction "insufficient oil pressure in a warm engine"

- wear of the working surfaces of the hydraulic clearance compensators in the valve drive, caused by the use of low-quality oil or its untimely replacement

Replace hydraulic lifters

- broken valve spring

Replace the spring

- Excessive clearance between valve stem and guide bushing caused by wear

Replace the valve with an oversize valve by reversing the valve guide hole accordingly

- camshaft lobes wear

Replace the camshaft

Knocking on a cold engine, audible for two to three minutes after starting and increasing with increasing crankshaft speed

- increased clearance between pistons and cylinders

Piston knocking that disappears after the engine warms up is not a sign of a malfunction. With constant knocking, replace the pistons, bore and hone the cylinders

- contamination of the working surfaces of the hydraulic compensators in the valve drive

Disassemble the valve drive, clean the working surfaces of the hydraulic lifters from dirt

- loosening of the vibration damper or pulleys

Tighten the mount

Short-term knocks immediately after starting the engine

- using the wrong brand of oil (low viscosity)

Change the recommended oil

- increased crankshaft clearance

Replace the middle main bearing shells

- increased clearance in the front main bearing

Replace front main bearing shells

Knocking in a warm engine at idle

- loosening or wear of auxiliary drive belts

Adjust or replace belts

- noise of parts of the gas distribution mechanism

See malfunction "increased noise of the gas distribution mechanism"

- using the wrong brand of oil

Change the recommended oil

- increased clearances between piston pins and holes in piston bosses

Replace pistons and pins

- increased clearances between crankshaft journals and liners

Replace the liners and sand the necks

- the axes of the upper and lower connecting rod heads are not parallel

Replace connecting rod

- the piston is incorrectly installed (displacement of the hole for the piston pin, directed to the left side of the engine)

Install the piston correctly

Strong knocks in a warm engine with an increase in the crankshaft speed

- failure of the torsional vibration damper or pulley hub

Replace damaged parts

- auxiliary drive belts are overtightened gaps or the appearance of breaks or cracks on them

Adjust belt tension, replace damaged belts

- loosened flywheel mount

Tighten the bolts to the recommended torque

- an excessive increase in the gaps between the shells of the connecting rod and main bearings of the crankshaft

Grind the crankshaft and replace the liners

Increased engine vibration

- crankshaft imbalance

Remove and balance the crankshaft

- pistons of different masses are installed

Disassemble the connecting rod and piston group, select pistons by weight

- unstable operation of hydraulic gap compensators in the valve drive

Disassemble the valve drive, clean the working surfaces of the hydraulic lifters, replace worn parts

- unequal compression values in cylinders

Replace worn parts

- the cushions of the suspension bearings of the power unit are badly worn or hardened

Replace supports

- the vibration damper or pulleys are loose

Tighten the bindings

Engine knocking when under load

- use of gasoline with a lower octane rating

Fill with the correct brand of gasoline

- spark plugs do not match the nominal

Replace spark plugs

- faulty electronic engine control unit

Replace block

Increased oil consumption

- oil leakage through the engine seals

Tighten fasteners or replace gaskets and seals

- the crankcase ventilation system is clogged

Clean the parts of the crankcase ventilation system

- wear of piston rings or engine cylinders

Rebore cylinders and replace pistons and rings

- breakage of piston rings

Replace rings

- coking of oil scraper rings or grooves in piston grooves

Clean the rings and grooves from soot, change the engine oil

- wear or damage to valve stem seals

Replace oil seals

- increased wear of valve stems or guide bushings

Replace valves, repair cylinder head

Engine overheating

- insufficient amount of liquid in the cooling system

Add coolant to the cooling system

- the outer surface of the radiator is heavily soiled

Clean the outer surface of the radiator with a jet of water

- the thermostat is faulty

Replace thermostat

- the electric fan of the cooling system is faulty

Check fan motor, replace defective parts

- the expansion tank plug valve is faulty (constantly open, due to which the system is under atmospheric pressure)

Replace expansion tank cap

- use of gasoline with a lower octane rating

Fill with qualified gasoline