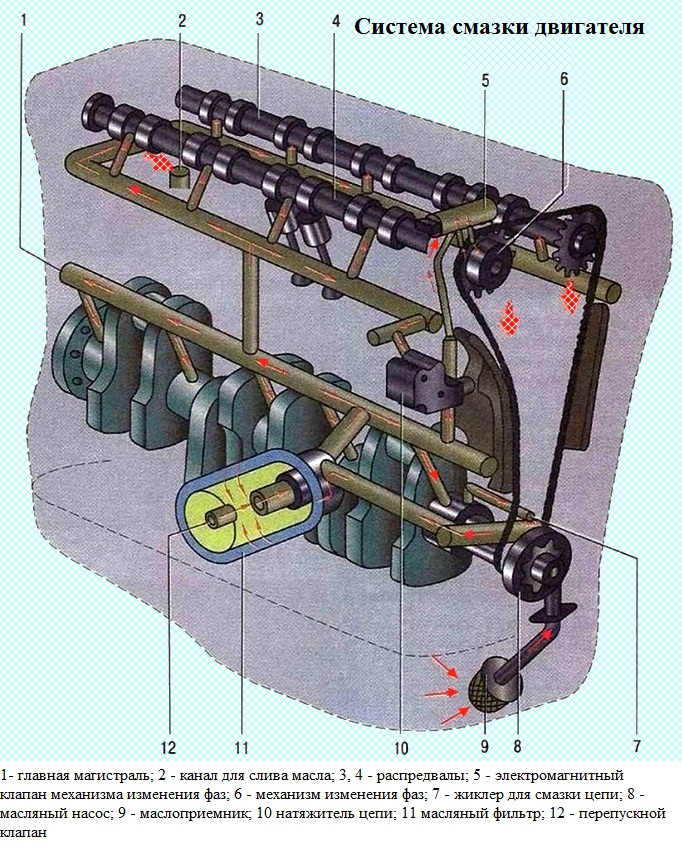

Oil system design features

Combined engine lubrication system: the most loaded parts are lubricated under pressure, the rest - by spraying

The pressure in the lubrication system is generated by a gear oil pump installed in the engine oil sump at the front of the cylinder block and driven by a chain drive from the crankshaft.

The pump draws oil from the engine oil sump through an oil receiver with a strainer and then through a full-flow oil filter with a porous paper filter element to the main oil line located in the body of the cylinder block on the left side.

The channels for supplying oil to the main bearings of the crankshaft depart from the main line.

Oil is supplied to the connecting rod bearings through channels made in the body of the crankshaft.

A channel for supplying oil to the camshaft departs from the main oil line.

In addition, from the main engine line, oil is supplied under pressure to the timing chain tensioner and to the intake valve timing system.

To lubricate the camshaft bearings, oil from the vertical channel through a radial hole in the neck of the third bearing flows through a hollow bolt into the axial hole of the rocker arm axis, through which it is distributed between the remaining camshaft bearings and the rocker arms of the valve drive.

The camshaft cams are lubricated with oil sprayed through holes in the rocker arms.

From the head of the block, excess oil is drained into the oil sump through vertical drainage channels.