The Niva Chevrolet controller (electronic control unit), located under the instrument panel on the right side, is the control center of the fuel injection system

It continuously processes information from various sensors and manages systems that affect exhaust emissions and vehicle performance.

The controller receives the following information:

- - about the position and frequency of rotation of the crankshaft;

- – about the mass air consumption of the engine;

- – coolant temperature;

- - throttle position;

- - about the oxygen content in the exhaust gases;

- - about the presence of detonation in the engine;

- - about the voltage in the vehicle's on-board network;

- – vehicle speed;

- - about the position of the camshaft (in a system with sequential distributed fuel injection);

- – about the request to turn on the air conditioner (if it is installed on the car).

Based on the information received, the controller controls the following systems and devices:

- - fuel supply (injectors and electric fuel pump);

- - ignition system;

- - idle control;

- – adsorber of the gasoline vapor recovery system;

- - fans of the engine cooling system;

- - air conditioning compressor clutch (if it is on the car);

- – diagnostic system.

The controller turns on the output circuits (injectors, various relays, etc.) by shorting them to ground through the output transistors of the controller.

The only exception is the fuel pump relay circuit. The controller supplies +12 V only to the winding of this relay.

The controller has a built-in diagnostic system. It can recognize malfunctions in the system, warning the driver about them through the "CHECK ENGINE" warning lamp.

In addition, it stores diagnostic codes indicating fault areas to help repair technicians.

There are three types of memory in the controller: random access memory (RAM), one-time programmable read-only memory (PROM), and electrically programmable memory (EPROM).

Random Access Memory is the "notebook" of the controller.

The microprocessor of the controller uses it for temporary storage of measured parameters, for calculations and for intermediate information.

The microprocessor can input or read data as needed.

The RAM chip is mounted on the controller PCB. This memory is volatile and requires an uninterruptible power supply to maintain.

When the power supply is interrupted, the diagnostic trouble codes and calculated data contained in the RAM are erased.

Programmable Read Only Memory (PROM)

The PROM contains a common program that contains a sequence of operating commands (control algorithms) and various calibration information.

This information is control data for injection, ignition, idle, etc., depending on vehicle weight, engine type and power, transmission ratios, and other factors. PROM is also called a calibration memory.

The contents of the PROM cannot be changed after programming.

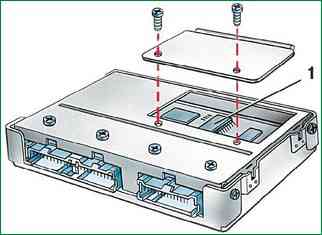

This memory does not need power to store the information stored in it, which is not erased when the power is turned off, i. this memory is non-volatile. The PROM is installed in the socket on the controller board 1 (Fig. 1) and can be removed from the controller and replaced.

EPROM is individual for each vehicle configuration, although the same unified controller can be used on different car models.

It is therefore important to set the correct model number and vehicle equipment when replacing the PROM. And when replacing a defective controller, you must leave the old PROM (if it is working).

Electrically Programmable Memory is used for temporary storage of vehicle anti-theft (immobilizer) password codes.

The password codes received by the controller from the immobilizer control unit (if available on the car) are compared with the codes stored in the EEPROM, and the engine start is allowed or prohibited. This memory is non-volatile and can be stored without power to the controller.